Method for preparing graphene doped polyaniline-based carbon coated nickel zinc ferrite mesoporous material

A technology of nickel-zinc ferrite and carbon-coated nickel, which is applied in ceramic products, applications, household appliances, etc., can solve the problems of narrow wave-absorbing frequency band and high density, and achieve excellent performance, high conductivity, and good size Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

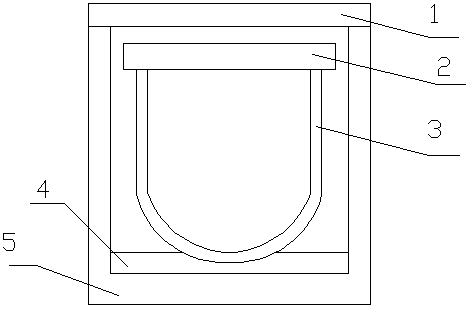

Image

Examples

Embodiment 1

[0028] A preparation method of graphene-doped polyaniline-based carbon-coated nickel-zinc ferrite mesoporous material, the specific steps are as follows:

[0029] (1) Preparation of Ni by self-propagating combustion method 0.6 Zn 0.4 Fe 2 o 4 magnetic nanoparticles

[0030] Weigh 0.03mol Ni(NO 3 ) 2 ·6H 2 O, 0.02mol Zn(NO 3 ) 2 ·6H 2 O and 0.1molFe(NO 3 ) 3 9H 2 Dissolve O in a three-necked flask with 100ml of deionized water, ultrasonically disperse, mix, then add 0.1mol of citric acid, adjust the pH to 7.0 with ammonia water, stir quickly for 5min, transfer the mixture to a 65°C water bath and oscillate with microwave until brown-red When the transparent sol appears, transfer the sol to a constant temperature drying oven at 75°C to dry until the xerogel is formed, add 1ml of absolute ethanol to the xerogel, ignite the xerogel in the air, and self-propagation can occur Combustion produces brown Ni 0.6 Zn 0.4 Fe 2 o 4 powder, and finally put the obtained powde...

Embodiment 2

[0038] A preparation method of graphene-doped polyaniline-based carbon-coated nickel-zinc ferrite mesoporous material, the specific steps are as follows:

[0039] (1) Preparation of Ni by self-propagating combustion method 0.6 Zn 0.4 Fe 2 o 4 magnetic nanoparticles

[0040] Weigh 0.03mol Ni(NO 3 ) 2 ·6H 2 O, 0.02mol Zn(NO 3 ) 2 ·6H 2 O and 0.1molFe(NO 3 ) 3 9H 2 Dissolve O in a three-necked flask with 100ml of deionized water, ultrasonically disperse, mix, then add 0.1mol of citric acid, adjust the pH to 7.0 with ammonia water, stir for 5 minutes, transfer the mixture to a 70°C water bath and oscillate with microwave until brown-red When the transparent sol appears, transfer the sol to a constant temperature drying oven at 80°C to dry to form a xerogel, add 2ml of absolute ethanol to the xerogel, and ignite the xerogel in the air, and self-propagation can occur Combustion produces brown Ni 0.6 Zn 0.4 Fe 2 o 4 powder, and finally put the obtained powder into a ...

Embodiment 3

[0048] A preparation method of graphene-doped polyaniline-based carbon-coated nickel-zinc ferrite mesoporous material, the specific steps are as follows:

[0049] (1) Preparation of Ni by self-propagating combustion method 0.6 Zn 0.4 Fe 2 o 4 magnetic nanoparticles

[0050] Weigh 0.03mol Ni(NO 3 ) 2 ·6H 2 O, 0.02mol Zn(NO 3 ) 2 ·6H 2 O and 0.1molFe(NO 3 ) 3 9H 2 Dissolve O in a three-necked flask filled with 100ml deionized water, ultrasonically disperse, mix, then add 0.1mol citric acid, adjust pH=7.0 with ammonia water, stir quickly for 5min, transfer the mixture to a 75°C water bath and oscillate with microwave until brown-red When the transparent sol appears, transfer the sol to a constant temperature drying oven at 85°C to dry until the xerogel is formed, add 3ml of absolute ethanol to the xerogel, and ignite the xerogel in the air, and self-propagation can occur Combustion produces brown Ni 0.6 Zn 0.4 Fe 2 o 4 powder, and finally put the obtained powder ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com