Special nickel-zinc ferrite material for integrated high frequency electrodeless discharge lamp inductive coupler and preparation method

An inductive coupler and nickel-zinc ferrite technology, which is applied in the field of nickel-zinc ferrite materials and preparation for the inductive coupler of an integrated high-frequency electrodeless lamp, can solve the problem of easy generation of electromagnetic radiation, difficulties in product miniaturization, and product heat generation. Concentration and other problems, to achieve the effect of improving electromagnetic loss characteristics, wide pre-burning and sintering temperature range, and good product consistency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

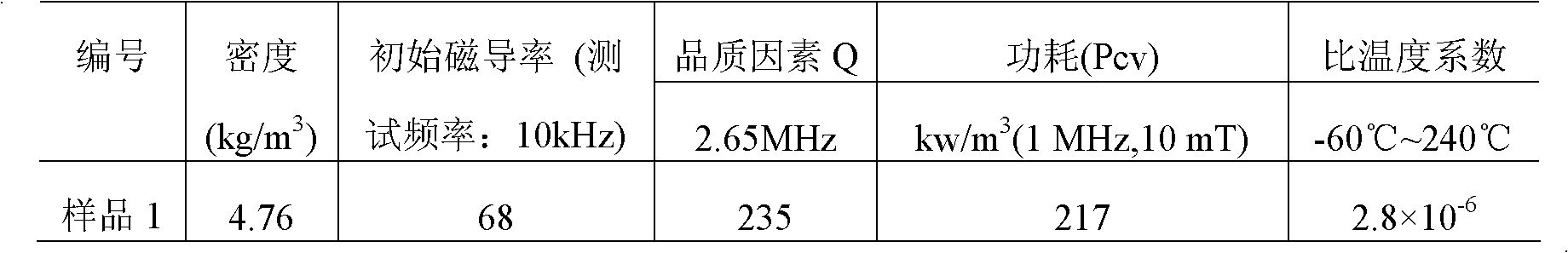

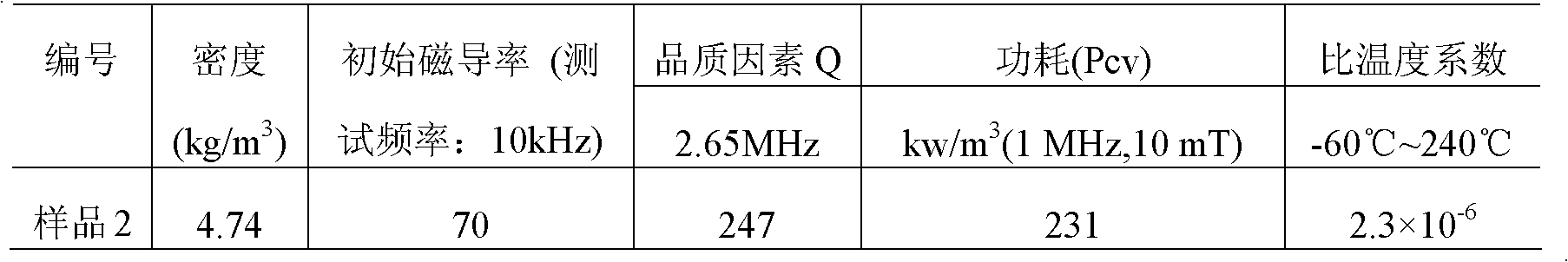

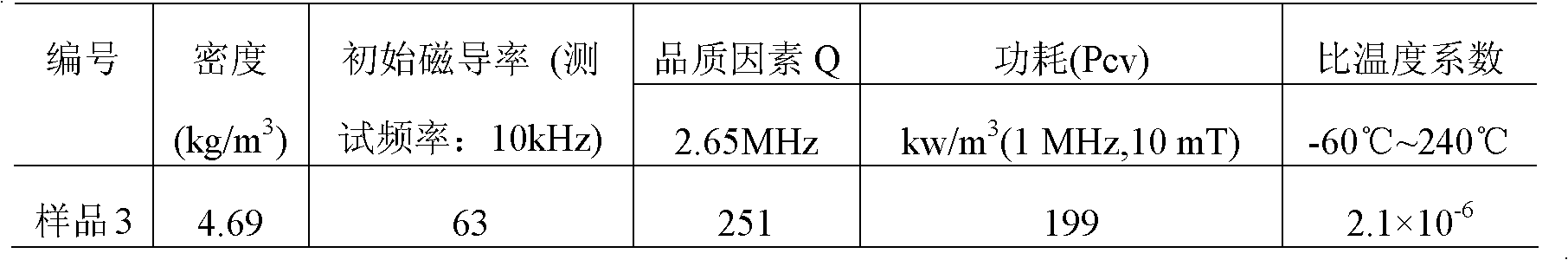

Embodiment 1

[0023] The nickel-zinc ferrite material for the integrated high-frequency electrodeless lamp inductive coupler provided in this embodiment has a spinel structure as its main phase, and its composition includes Fe 2 o 3 , ZnO, NiO and Co 2 o 3 , and its composition content is calculated as oxides: Fe 2 o 3 48mol%~56mol%; ZnO 15mol%~22mol%; NiO 20mol%~33mol%; Co 2 o 3 It is 0.001mol% to 0.004mol%, and it also contains 0.05wt% to 0.15wt% of the total weight as a sintering flux that has been surface-modified by a silane coupling agent. 2 o 5 ; Nano-MnCO surface-modified by silane coupling agent 3 and CaCO 3 powder as an improved additive, in which nano-MnCO 3 The amount added is 0.2wt% to 0.5wt% of the total weight; nano-CaCO 3 The added amount is 0.02wt%-0.05wt% based on the total weight.

[0024] The preparation method of the nickel-zinc ferrite material for the integrated high-frequency electrodeless lamp inductive coupler provided in this embodiment is as follows: ...

Embodiment 2

[0044] 1) Selection of raw materials: The present invention provides ultra-wide temperature, high stability and extremely low electromagnetic loss at high frequency and high current, and can be applied to the production of nickel-zinc ferrite materials for integrated high-frequency electrodeless lamp power couplers. Raw materials choose industrially pure Fe 2 o 3 , ZnO, NiO and Co 2 o 3 .

[0045] 2) Composition design and weighing: according to Fe 2 o 3 is 56mol%, ZnO is 15mol%, NiO is 28.999mol% and Co 2 o 3 It is 0.001 mol%.

[0046] 3) Mixing of raw materials: Put the weighed raw materials into a sand mill, add deionized water, the weight of deionized water is 1.2 times of the total weight of raw materials, and the ball milling time is 2 hours.

[0047] 4) Pre-burning: Dry the raw materials that have been ball-milled once, and put them into an electric furnace for pre-burning. The pre-burning temperature is 1020°C, and the pre-burning time is 3.5 hours. After pre-b...

Embodiment 3

[0057] 1) Selection of raw materials: The present invention provides ultra-wide temperature, high stability and extremely low electromagnetic loss at high frequency and high current, and can be applied to the production of nickel-zinc ferrite materials for integrated high-frequency electrodeless lamp power couplers. Raw materials choose industrially pure Fe 2 o 3 , ZnO, NiO and Co 2 o 3 .

[0058] 2) Composition design and weighing: according to Fe 2 o 3 is 48mol%, ZnO is 22mol%, NiO is 29.994mol% and Co 2 o 3 It is 0.004 mol%.

[0059] 3) Mixing of raw materials: Put the weighed raw materials into a sand mill, add deionized water, the weight of deionized water is 1.2 times of the total weight of raw materials, and the ball milling time is 1 hour.

[0060] 4) Pre-burning: Dry the raw materials that have been ball-milled once, and put them into an electric furnace for pre-burning. The pre-burning temperature is 1180°C, and the pre-burning time is 1.5 hours. After pre-bu...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Average particle size | aaaaa | aaaaa |

| Size | aaaaa | aaaaa |

| Melting point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com