Manganese-zinc ferrite material and preparation method thereof

A technology of manganese zinc ferrite and powder, which is applied in the field of manganese zinc ferrite material and its preparation, can solve the problems of large Curie temperature of 150°C and low temperature coefficient, and achieve high Curie temperature and low temperature The effect of the coefficient

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

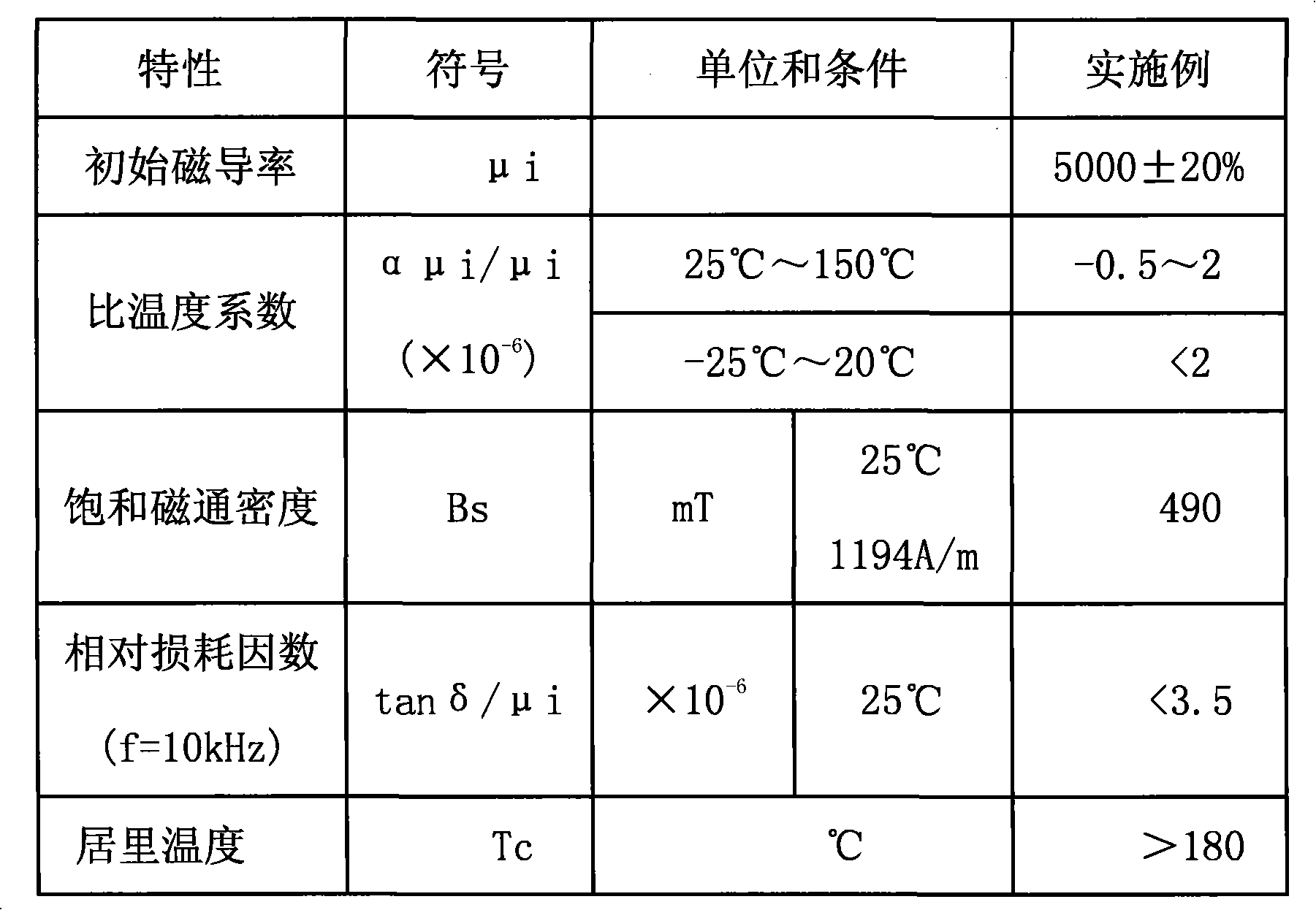

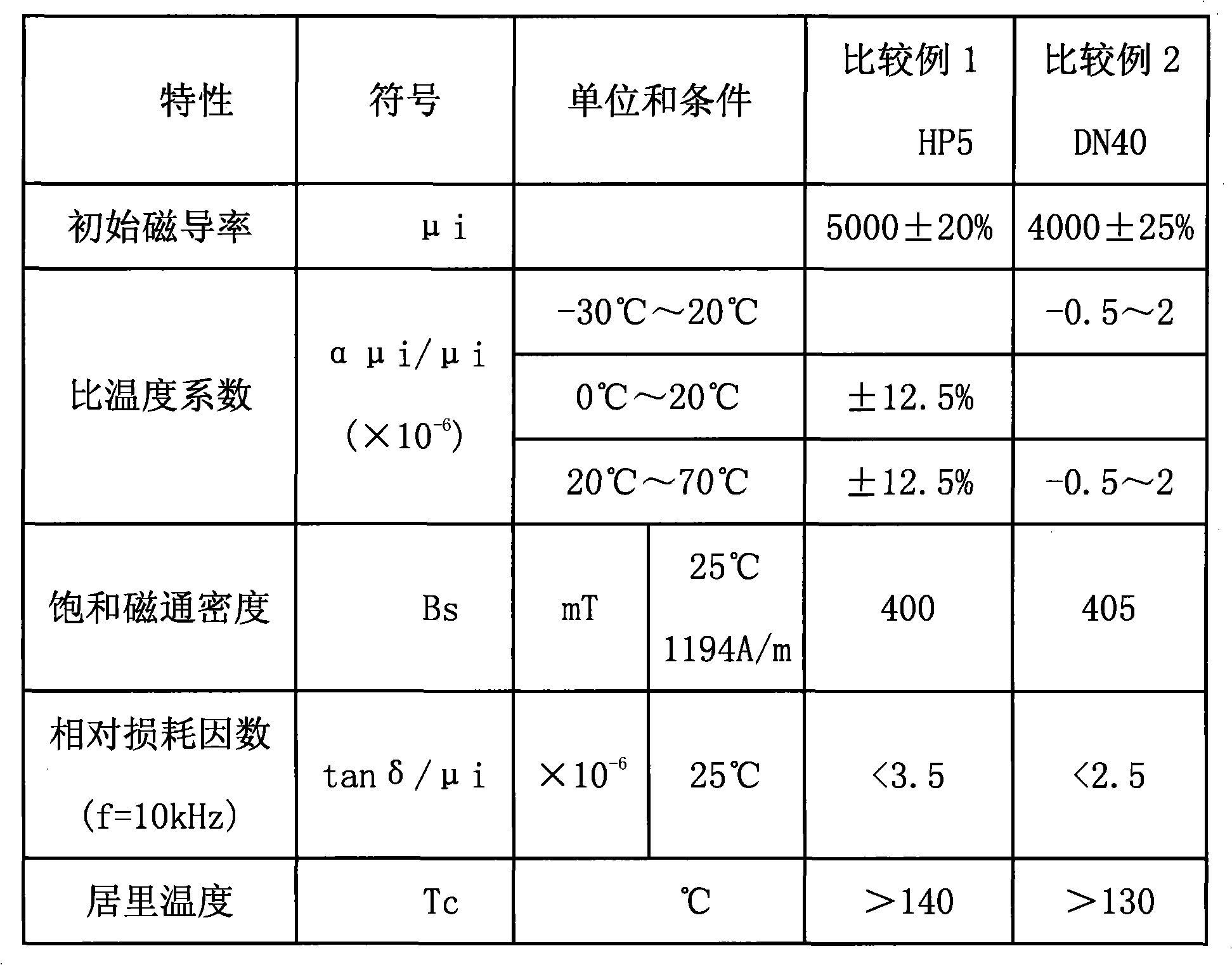

Examples

Embodiment 1

[0024] Embodiment 1 Manganese zinc ferrite material is made up of main component and additive, and its main component (mol percentage) is: 52.5% Fe 2 o 3 Powder, 10% ZnO powder, 37.5% MnO powder; additives (accounting for the percentage of the total weight of main components) include 0.01% CaO powder, 0.1% TiO 2 Powder, 0.01% Co 2 o 3 Powder; additives also include 0.01% V 2 o 5 , 0.01% Bi 2 o 3 , 0.01% MoO 3 .

Embodiment 2

[0025] Embodiment 2 Manganese zinc ferrite material is made up of main component and additive, and its main component (mol percentage) is: 53.5% Fe 2 o 3 Powder, 15% ZnO powder, 31.5% MnO powder; additives (accounting for the percentage of the total weight of main components) include 0.05% CaO powder, 0.2% TiO 2 Powder, 0.15% Co 2 o 3 Powder; additives also include 0.05% V 2 o 5 , 0.05% Bi 2 o 3 .

Embodiment 3

[0026] Embodiment 3 Manganese zinc ferrite material is made up of main component and additive, and its main component (mol percentage) is: 55% Fe 2 o 3 Powder, 18% ZnO powder, 27% MnO powder; Additives (accounting for the percentage of main component total weight) include 0.2% CaO powder, 0.5% TiO 2 Powder, 0.5% Co 2 o 3 Powder; additives also include 0.2% V 2 o 5 .

[0027] The preparation method of manganese zinc ferrite material of the present invention comprises the following steps:

[0028] 1) Prepare the main component powder and mix the main component powder evenly;

[0029] 2), pre-burn the powder obtained in step 1) at 800-1150°C, and the holding time for pre-burning is 0.2-4 hours;

[0030] 3), adding additives to the powder obtained in step 2) according to the mass percentage and further pulverizing, then adding PVA solution and sanding it into slurry;

[0031] 4), the slurry obtained in step 3) is spray-dried, granulated, and pressed into a green sample.

...

PUM

| Property | Measurement | Unit |

|---|---|---|

| The average particle size | aaaaa | aaaaa |

| Curie temperature | aaaaa | aaaaa |

| Curie temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com