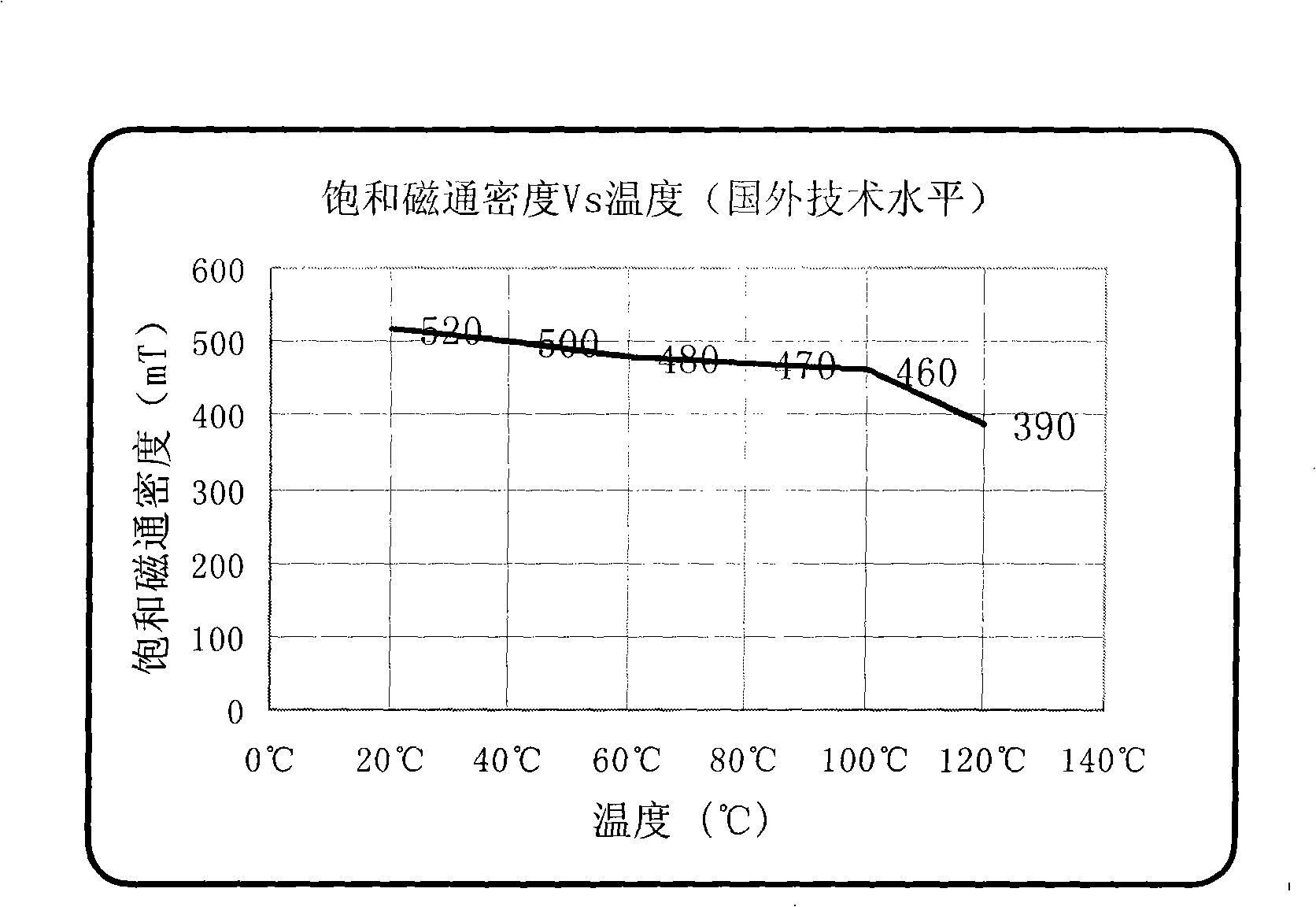

Manganese-zinc ferrite material of high performance and power, and manufacturing method therefor

A technology of manganese zinc ferrite and its manufacturing method, which is applied in the direction of magnetism of inorganic materials, and achieves the effect of low production cost and good innovation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] The present invention manufactures a certain specific method of high-performance power manganese-zinc ferrite soft magnetic material and magnetic core, successively through the following process:

[0029] (1) main ingredient ingredients;

[0030] (2) Primary crushing: Put the raw materials prepared according to the composition into the sand mill tank for wet sanding for 30 minutes, let the three raw materials be fully mixed evenly, and add a certain proportion of dispersant before and after sanding;

[0031] (3) Pre-burning: dry the sanded powder and pre-fire, the pre-burning temperature is 800 ° C, keep warm for 2 to 3 hours;

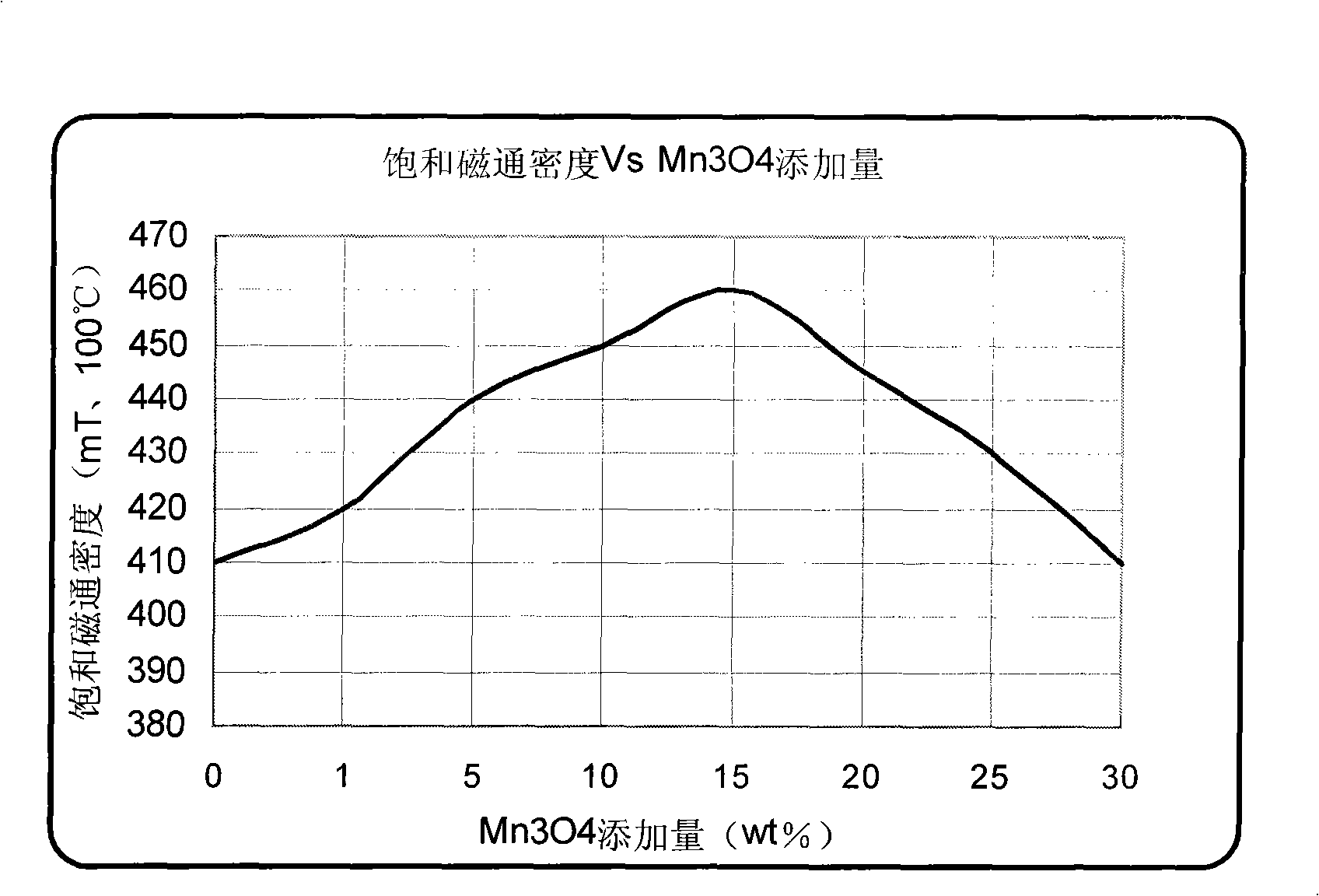

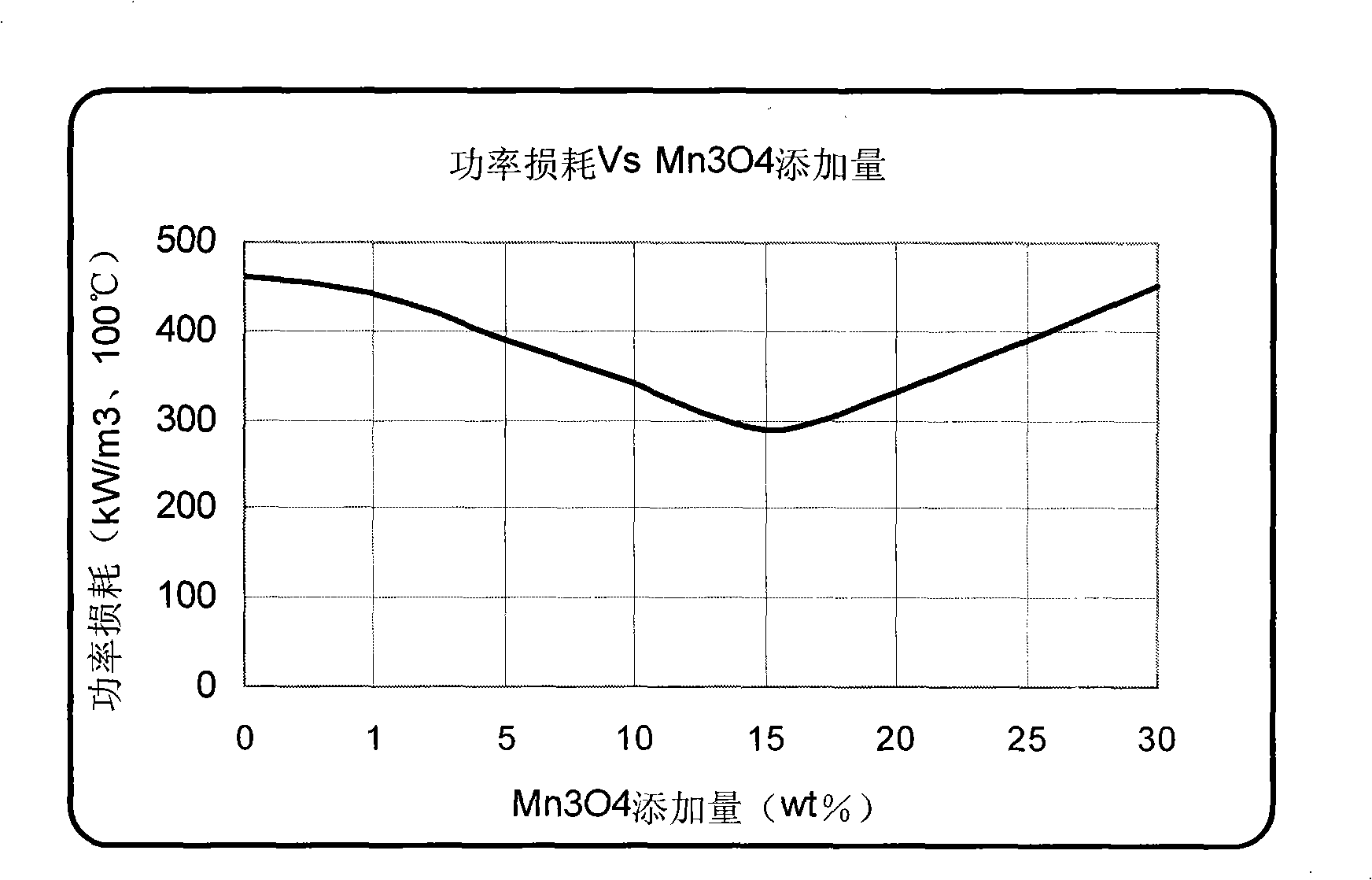

[0032] (4) Adding additives: adding a large amount of Mn 3 o 4 (1 ~ 20wt%, the best addition range is 13 ~ 18wt%) and 0.05 ~ 0.08wt% CaCO 3 , 0.03~0.06wt%V 2 o5 , 0.03~0.07wt% Nb 2 o 5 , 0.05~0.15wt%SnO 2 , the total amount added is between 1.15 and 20.25 wt%.

[0033] (5) Secondary crushing: Put the pre-burned main ingredients and addit...

PUM

| Property | Measurement | Unit |

|---|---|---|

| core loss | aaaaa | aaaaa |

| core loss | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com