Magnetically enhanced resin

A technology for reinforcing resins and resins, applied in the direction of magnetic coatings, inorganic materials, coatings, etc., can solve the problems of low magnetic permeability and limited use, and achieve the effect of increasing magnetic permeability and reducing magnetoresistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0075] First, 8.0 parts by weight of the resin A, 91.9 parts by weight of the ferromagnetic material, and 0.1 parts by weight of Pc were blended. About 5 mL of butyl carbitol (manufactured by Wako Pure Chemical Industries, Ltd.) and about 3 mL of methyl ethyl ketone (MEK) (manufactured by Wako Pure Chemical Industries, Ltd.) were added thereto and mixed using a planetary mixer to prepare magnetic enhancement resin.

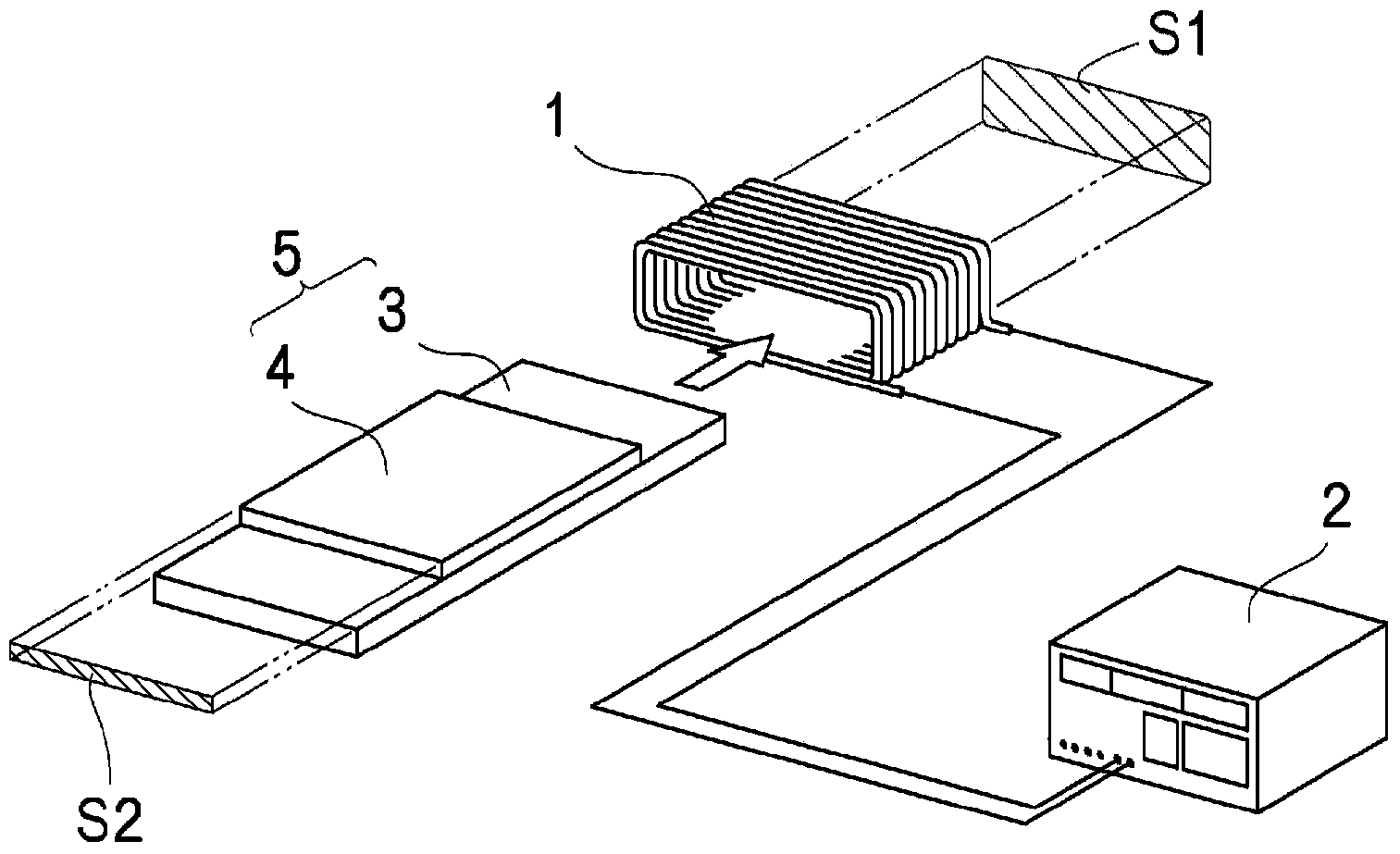

[0076] The thickness t of the optical microscope slide 3 (manufactured by As One Corp.) was measured with a micrometer (manufactured by Mitutoyo Co., Ltd., measuring range: 1 μm to 25 mm) 0 . The magnetic enhancement resin was applied to the optical microscope slide 3 in such a manner that the coating thickness was about 100 μm. It was calcined at about 160° C. for about 30 minutes using an electric oven to form the magnetic enhancement resin layer 4 . The slide glass 3 for an optical microscope and the magnetically enhanced resin layer 4 are collectively refer...

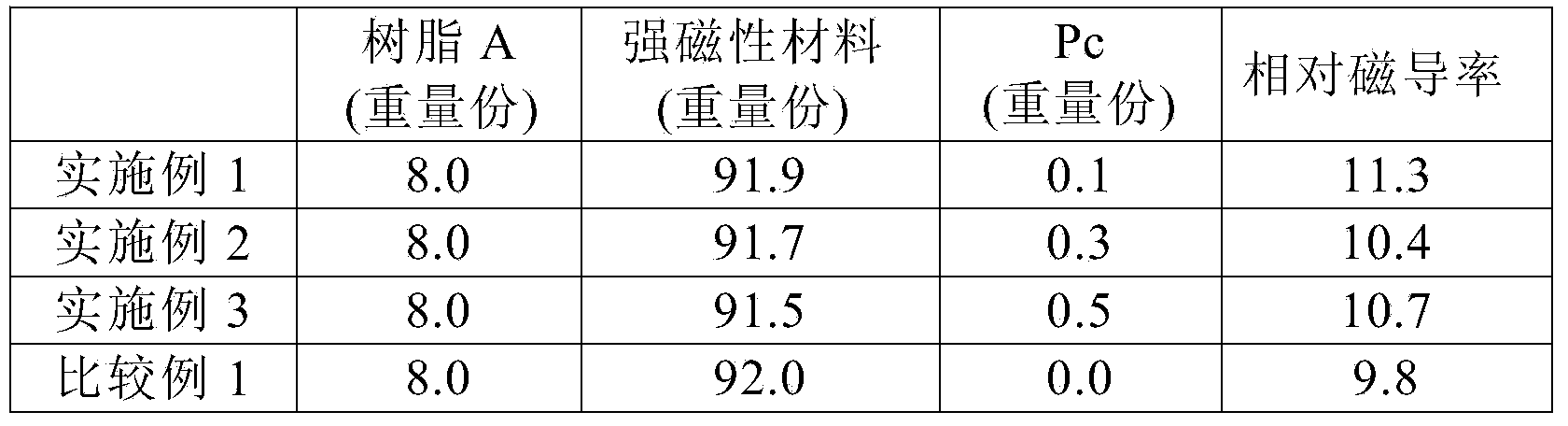

Embodiment 2 and 3 and comparative example 1

[0081] The operation was carried out in the same manner as in Example 1 except that the blending ratio of the materials used was as shown in Table 1. The blending ratio and the results are shown in Table 1. The amounts of each blended material in Table 1 are expressed in parts by weight relative to 100 parts by weight of solid content.

[0082] Table 1

[0083]

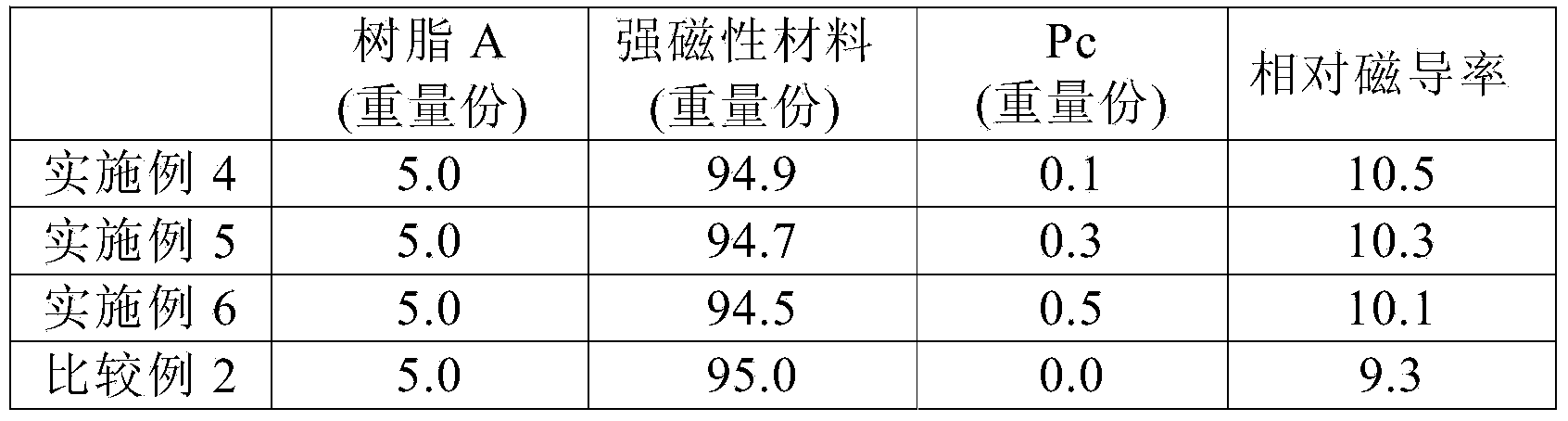

Embodiment 4~6 and comparative example 2

[0085] In order to prepare a test body, the operation was carried out in the same manner as in Example 1 except that the blending ratio of the materials used was as shown in Table 2. The blending ratios and results are shown in Table 2.

[0086] Table 2

[0087]

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com