Unit block used in manufacturing core with soft magnetic metal powder, and method for manufacturing core with high current DC bias characteristics using the unit block

A technology of metal powder and unit block, applied in the direction of magnetic core/yoke, inductor/transformer/magnet manufacturing, circuit, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0030] The preparation of the soft magnetic metal powder of the present invention will be described below.

[0031] The sendust powder used in the present invention was prepared according to the same method of Korean Patent Application No. 1998-62927 done by the applicant of the present invention, and the preparation of the powder is briefly described below.

[0032]Use a jaw crusher, a rotary crusher or a hammer mill to crush the sendust aluminum alloy ingot, which has high magnetic permeability and low loss properties, and is composed of 9.6% Si, 5.4 % of aluminum and the rest of Fe; treated with a ball mill for 1 hour, heat treated at 800°C to 900°C for 8 hours in a mixed gas atmosphere of hydrogen and nitrogen. The sendust powder is prepared by treating the heat-treated powder by wet insulating coating using 1.0 wt% to 2.0 wt% insulating ceramic or by dry insulating coating using a low melting point ceramic binder.

[0033] The preparation of high-throughput powder consis...

Embodiment 1

[0046] A sendust ingot having high magnetic permeability and low loss characteristics and composed of 9.6% by weight of Si, Composition of 5.4% by weight of Al and the balance of Fe. Preparation of sendust powder is accomplished by treating sendust powder by wet insulating coating using 1.0% by weight of mixed ceramics or by dry insulating coating using glass frit (Korean Patent Application No. 1998 -62927).

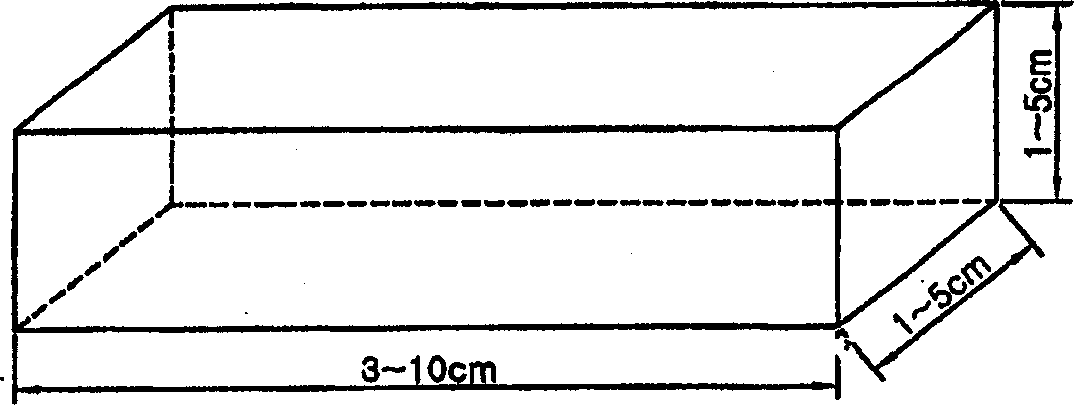

[0047] After adding a lubricant to the coated sendust powder, the obtained powder is pressed into a unit block with a length of 60 mm, a width of 30 mm and a height of 20 mm with a high pressing pressure of 100 tons to 500 tons, and then heated at 700 ° C Heat treatment at ~800° C. for 1 hour in a nitrogen atmosphere, so as to complete the manufacture of the unit block for the magnetic core.

Embodiment 2

[0049] Preparation of FeNiMo powder (Korean Patent Application No. 1997-0009412) was accomplished by treating the powder (FeNiMo) by wet insulating coating with 1.0% by weight of mixed ceramics, the powder (FeNiMo) Molybdenum) has a particle size equal to or less than 300 mesh (50 μm), is produced by a spray method, and consists of 2% Mo, 80% Ni and the balance Fe.

[0050] After adding stearic acid as a lubricant to the coated iron-nickel-molybdenum powder, the resulting powder is pressed into a unit block with a length of 60 mm, a width of 30 mm, and a height of 20 mm at a high pressing pressure of 100 tons to 500 tons, Then heat treatment at 700° C.-800° C. for 1 hour in a nitrogen atmosphere, so as to complete the manufacture of the unit block for the magnetic core.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size (mesh) | aaaaa | aaaaa |

| noise | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com