Graphene-containing lightweight anti-electromagnetic pollution composite material plate and preparation method

A composite material board and graphene technology, applied in chemical instruments and methods, synthetic resin layered products, layered products, etc., can solve problems such as unsatisfactory microwave absorption, inability to form conductive networks, poor interface bonding, etc., to achieve Enhance interface scattering and polarization, increase interface bonding area, good damping effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

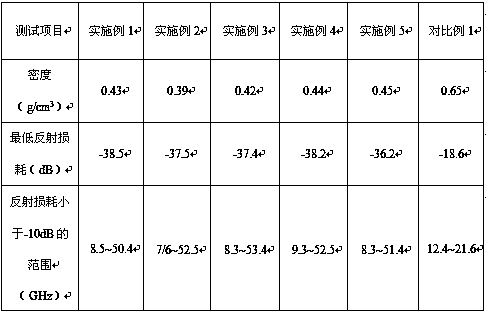

Examples

Embodiment 1

[0034] a. Mix graphene and foaming agent uniformly, add it to the temperature-sensitive capsule material, and spray-dry to prepare graphene / foaming agent microcapsules coated with temperature-sensitive capsule material, namely microcapsule A;

[0035] b. Mix the nano ferrite and the foaming agent uniformly, add them to the temperature-sensitive capsule material, and spray-dry to prepare the temperature-sensitive capsule material-coated nano ferrite / foaming agent microcapsules, namely microcapsules B;

[0036] c. Mix sendust and foaming agent uniformly, add them to the temperature-sensitive capsule material, and spray-dry to prepare the temperature-sensitive capsule material-coated sendust / foaming agent microcapsules, namely microcapsule C;

[0037] d. Mix the microcapsule A with polyolefin and processing aids to prepare the first polyolefin composition, namely composition A;

[0038] e. Mix the microcapsule B with polyolefin and processing aids to prepare the first polyolefin composit...

Embodiment 2

[0044] a. Mix graphene and foaming agent uniformly, add it to the temperature-sensitive capsule material, and spray-dry to prepare graphene / foaming agent microcapsules coated with temperature-sensitive capsule material, namely microcapsule A;

[0045] b. Mix the nano ferrite and the foaming agent uniformly, add them to the temperature-sensitive capsule material, and spray-dry to prepare the temperature-sensitive capsule material-coated nano ferrite / foaming agent microcapsules, namely microcapsules B;

[0046] c. Mix sendust and foaming agent uniformly, add them to the temperature-sensitive capsule material, and spray-dry to prepare the temperature-sensitive capsule material-coated sendust / foaming agent microcapsules, namely microcapsule C;

[0047] d. Mix the microcapsule A with polyolefin and processing aids to prepare the first polyolefin composition, namely composition A;

[0048] e. Mix the microcapsule B with polyolefin and processing aids to prepare the first polyolefin composit...

Embodiment 3

[0054] a. Mix graphene and foaming agent uniformly, add it to the temperature-sensitive capsule material, and spray-dry to prepare graphene / foaming agent microcapsules coated with temperature-sensitive capsule material, namely microcapsule A;

[0055] b. Mix the nano ferrite and the foaming agent uniformly, add them to the temperature-sensitive capsule material, and spray-dry to prepare the temperature-sensitive capsule material-coated nano ferrite / foaming agent microcapsules, namely microcapsules B;

[0056] c. Mix sendust and foaming agent uniformly, add them to the temperature-sensitive capsule material, and spray-dry to prepare the temperature-sensitive capsule material-coated sendust / foaming agent microcapsules, namely microcapsule C;

[0057] d. Mix the microcapsule A with polyolefin and processing aids to prepare the first polyolefin composition, namely composition A;

[0058] e. Mix the microcapsule B with polyolefin and processing aids to prepare the first polyolefin composit...

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

| porosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com