A method for preparing aluminum/magnesium/aluminum composite panels at a three-dimensional layer interface

A technology of aluminum composite panels and composite slabs, applied in the direction of manufacturing tools, metal rolling, welding equipment, etc., can solve the problems of difficult deformation, difficult to achieve metal sheet composite, limited application of corrugated rolling, etc., to achieve smooth surface, reduce The effect of combining interface defects and increasing the interface bonding area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment 1

[0036] Specific example one: use this method to prepare 2024 / AZ31 / 2024 composite board:

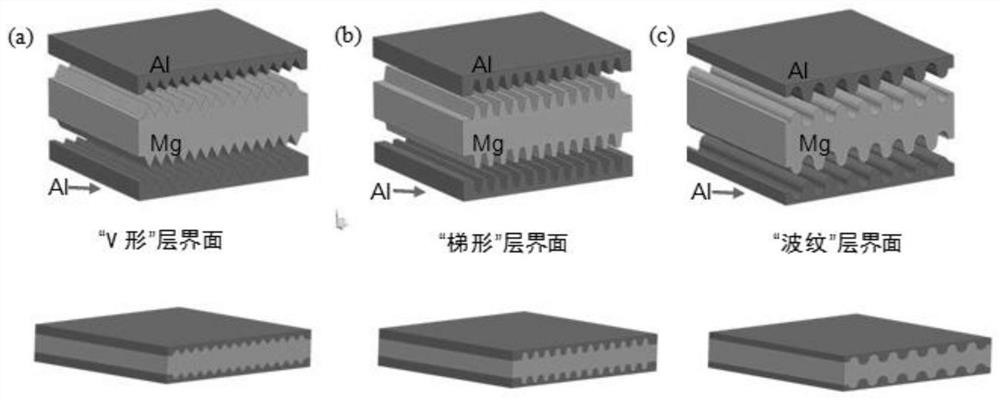

[0037] one, such as figure 1 As shown in (a), the surface of AZ31 and 2024 is machined with V-shaped layer interface protrusions that cooperate with each other. The size of the hot pressing die used is 60×100mm, so the machining size of AZ31 and 2024 alloys is 60×60;

[0038] 2. Clean the surface to be bonded of AZ31 and 2024, lightly brush the bonded surface with a brush, then use ultrasonic cleaning in alcohol solution and dry it;

[0039] 3. According to the order of 2024 / AZ31 / 2024, they are intermeshed and stacked to form composite slabs;

[0040]4. Put the composite slab into the hot-pressing mold, and the side perpendicular to the direction of the trapezoidal section is stuck in the mold. Before hot-pressing, apply boron nitride suspension on the surface of the mold to facilitate demoulding. When hot-pressing, the composite slab Keep warm in the mold at 400°C for 15min, then hot p...

specific Embodiment 2

[0045] Specific embodiment two: the difference between this embodiment and specific embodiment one is that in step one such as figure 1 As shown in (b) and (c), the V-shaped layer interface and corrugated layer interface protrusions that cooperate with each other are machined on the surface of AZ31 and 2024.

specific Embodiment 3

[0046] Specific embodiment three: the difference between this embodiment and specific embodiment one is that the magnesium described in step one is pure magnesium or any other plastically deformable magnesium alloy, aluminum is pure aluminum or any other plastically deformable aluminum alloy, and other It is the same as in the first embodiment.

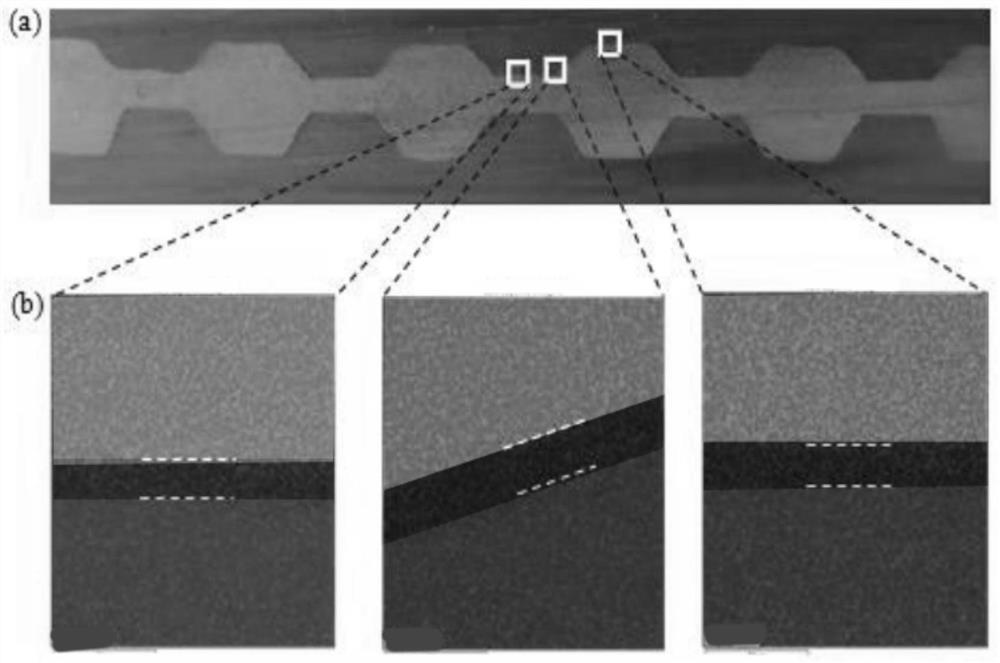

[0047] like figure 2 As shown, it is a schematic diagram of the composite slab after multiple unidirectional ultrasonic waves at the interface of the trapezoidal layer with variable temperature, variable load and heat pressing + rolling; where (a) is the physical cross-sectional view of the composite slab, and (b) is the white box in figure (a) Surface scan of elements in the region shown.

[0048] It can be seen from the figure that the use of multiple unidirectional ultrasonic variable temperature and load hot pressing + rolling two-step thermal deformation method can enhance the overall strength and plasticity of the laminate and...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com