Raise ha/zro 2 Method for Interfacial Bonding Force of Layered Composite Bioceramic Materials

A technology of bioceramic materials and composite bioceramics, applied in medical science, prosthesis, etc., can solve the problems of high price, heavy metal poisoning, and clinical application restrictions, and achieve the effect of low preparation cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0026] In this example, see Figure 1 ~ Figure 4 , an improved HA / ZrO 2 The method for interfacial binding force of layered composite bioceramic material comprises the following steps:

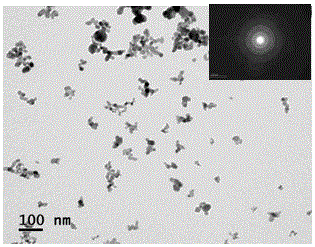

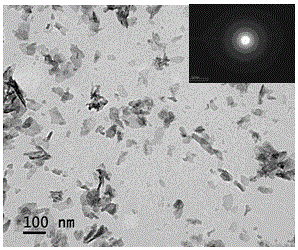

[0027] (1) Preparation of nano-ZrO by precipitation method 2 and HA powder, place the nano-powder in a drying oven and dry it completely for use, nano-ZrO 2 Powder and nano HA powder morphology see figure 1 ;

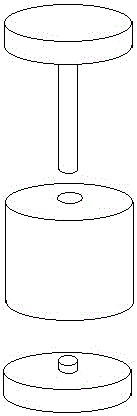

[0028] (2) Processing such as figure 2 The compression mold for the bioceramic disc specimen shown has a boss machined in the center of the male surface of the mold, see image 3 and Figure 4 , so that the surface of the male mold of the mold forms a convex pattern, which is processed by wire cutting, and its surface is polished on a polishing machine to remove burrs. The height of the processed boss is 0.5mm, the diameter is 5mm, and the shape of the boss is cylinder;

[0029] (3) Nano-ZrO prepared in step (1) 2 The powder is determined according to the required mass accordi...

Embodiment 2

[0034] This embodiment is basically the same as Embodiment 1, especially in that:

[0035] In this example, see Figure 5 , an improved HA / ZrO 2 The method for interfacial binding force of layered composite bioceramic material comprises the following steps:

[0036] (1) This step is the same as in Embodiment 1;

[0037] (2) Processing such as figure 2 The compression mold of the bioceramic disc sample shown, the wave pattern is processed on the surface of the male mold of the mold, see Figure 5 , so that the wavelength of the wave pattern processed on the surface of the male mold of the mold is 1mm, the amplitude is 0.5mm, and it is formed by wire cutting, and its surface is polished on a polishing machine to remove burrs;

[0038] (3) This step is the same as Embodiment 1;

[0039] (4) This step is the same as Embodiment 1;

[0040] (5) This step is the same as Embodiment 1;

[0041] (6) This step is the same as the first embodiment.

Embodiment 3

[0043] This embodiment is basically the same as the previous embodiment, and the special features are:

[0044] In this example, see Figure 6 , an improved HA / ZrO 2 The method for interfacial binding force of layered composite bioceramic material comprises the following steps:

[0045] (1) This step is the same as in Embodiment 1;

[0046] (2) Processing such as figure 2 For the pressing mold of the bioceramic disc sample shown, a grid pattern is processed on the surface of the male mold of the mold. The wavelength of the processed grid pattern is 1mm, and the amplitude is 0.5mm. See Figure 5 , when processing the grid pattern on the surface of the male mold, first process a wave pattern on the surface of the male mold of the mold, and then on the basis of the previous wave pattern, keep an inclination of 60 degrees with the previous wave pattern on the surface of the male mold The second wave pattern is processed at an angle of °, so that the two processed wave pattern...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com