Magnetic metal powder with high forming density, low molding pressure and surface insulation

A technology of magnetic metal powder and molding pressure, applied in the field of magnetic metal powder, can solve the problems of high hardness, incomplete performance of magnetic powder core, low molding pressure, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

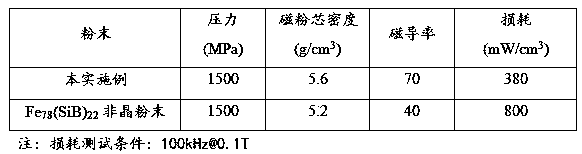

[0018] This example uses Fe 78 (SiB) 22 Atomized amorphous powder, approximately spherical in shape, with an average particle size D50 of 26um, and then using an anodic plating process to form a metal aluminum film with a thickness of 0.2um on its surface, and then heating it to 100°C in a phosphoric acid solution with a pH of 2.0 to react for 10 A layer of aluminum phosphate compound is formed in minutes, with a thickness of 0.05um; finally, the magnetic powder core is prepared by pressure molding and heat treatment. For comparison, Fe 78 (SiB) 22 Magnetic powder cores were prepared by water atomizing amorphous powder and the same process. Its performance is as follows:

[0019]

[0020] It can be seen from the above table that the use of the composite structure amorphous powder of the present invention can effectively reduce the loss of the magnetic powder core and increase the magnetic permeability, because the middle aluminum metal layer effectively relieves the str...

Embodiment 2

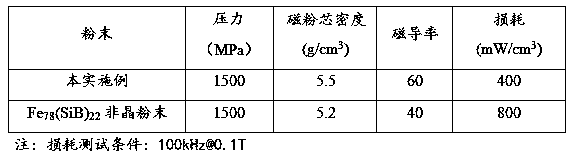

[0022] This example uses Fe 78 (SiB) 22 Water-atomized amorphous powder, approximately spherical in shape, with an average particle size D50 of 26um, and then a metal iron film with a thickness of 0.1um is formed on the surface by electroplating, and then heated to 100°C in a phosphoric acid solution with pH=2.0 to react for 10 A layer of iron phosphate compound is formed in minutes, with a thickness of 0.05um; finally, the magnetic powder core is prepared by pressure molding and heat treatment. For comparison, Fe 78 (SiB) 22 Magnetic powder cores were prepared by water atomizing amorphous powder and the same process. Its performance is as follows:

[0023]

[0024] It can be seen from the above table that the use of the composite structure amorphous powder of the present invention can effectively reduce the loss of the magnetic powder core and increase the magnetic permeability, because the iron metal layer in the middle effectively relieves the stress concentration an...

Embodiment 3

[0026] This example uses Fe 78 Si 9.6 al 5.4 The crushed powder is approximately spherical in shape, with an average particle size D50 of 45um; after that, a metal aluminum film with a thickness of 0.2um is formed on the surface by anodic plating process, and then heated to 100°C in a phosphoric acid solution with pH=2.0 for 10 minutes to form a A layer of aluminum phosphate compound with a thickness of 0.05um; finally, the magnetic powder core is prepared by pressure molding and heat treatment. For comparison, Fe 78 Si 9.6 al 5.4 Magnetic powder cores were prepared by water atomizing amorphous powder and the same process. Its performance is as follows:

[0027]

[0028] As can be seen from the above table, the use of the composite structure amorphous powder of the present invention can effectively reduce the loss of the magnetic powder core, because:

[0029] (1) The iron metal layer in the middle effectively relieves stress concentration;

[0030] (2) The plastic ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Volume average particle size | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com