Composite magnetic powder and preparation method therefor

A magnetic powder core and magnetic powder technology, applied in the manufacture of inductors/transformers/magnets, inorganic material magnetism, electrical components, etc., can solve the problems of improving magnetic permeability, high high frequency loss, unstable strength of insulating layer, etc. effect of increasing saturation magnetization and permeability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0028] The invention provides a kind of preparation method of composite magnetic powder, comprises the following steps:

[0029] a) Using a melt quenching method to prepare sendust aluminum alloy strips; during the preparation process, applying a directional magnetic field when the strips are thrown; breaking the prepared sendust aluminum alloy thin strips to obtain sendust aluminum alloy fragments;

[0030] b) Mixing and ball milling the sendust powder and ferrite powder to obtain composite magnetic powder.

[0031] In the preparation method provided by the present invention, sendust aluminum strips are firstly prepared. The invention adopts the melt rapid quenching method to prepare the iron-silicon-aluminum alloy thin strip, and always applies a directional magnetic field during the strip throwing process. In the present invention, the magnetic field strength of the orientation magnetic field is preferably 500-2000 Oe, more preferably 1000-1200 Oe. In the present inventio...

Embodiment 1

[0055] (1) In the induction type melt quenching equipment, prepare a standard composition iron-silicon-aluminum alloy strip (5.4wt% Al, 9.6wt% Si, the rest Fe) with a thickness of 5-15 μm. During the preparation of the alloy strip, the strip The rotational speed of the copper roller is 60m / s, and a directional magnetic field of 1000Oe is always applied during the belt throwing process. After the sendust strip is obtained, it is crushed in a stainless steel tank to obtain sendust fragments.

[0056] (2) with FeCl 3 , ZnCl 2 and MnCl 2 4H 2 O is the raw material, according to Mn 0.4 Zn 0.6 Fe 2 o 4 Middle Fe 3+ , Zn 2+ , Mn 2+ The molar ratio n[Fe 3+ ]:n[Zn 2+ ]:n[Mn 2+ ]=10:3:2 Weigh the required raw materials respectively, add an appropriate amount of deionized water, stir continuously to dissolve the raw material particles completely, and obtain a Fe-Zn-Mn mixed salt solution, heat it to 80°C, and drop in a concentration of 2mol / L of NaOH solution, stirred cons...

Embodiment 2~5

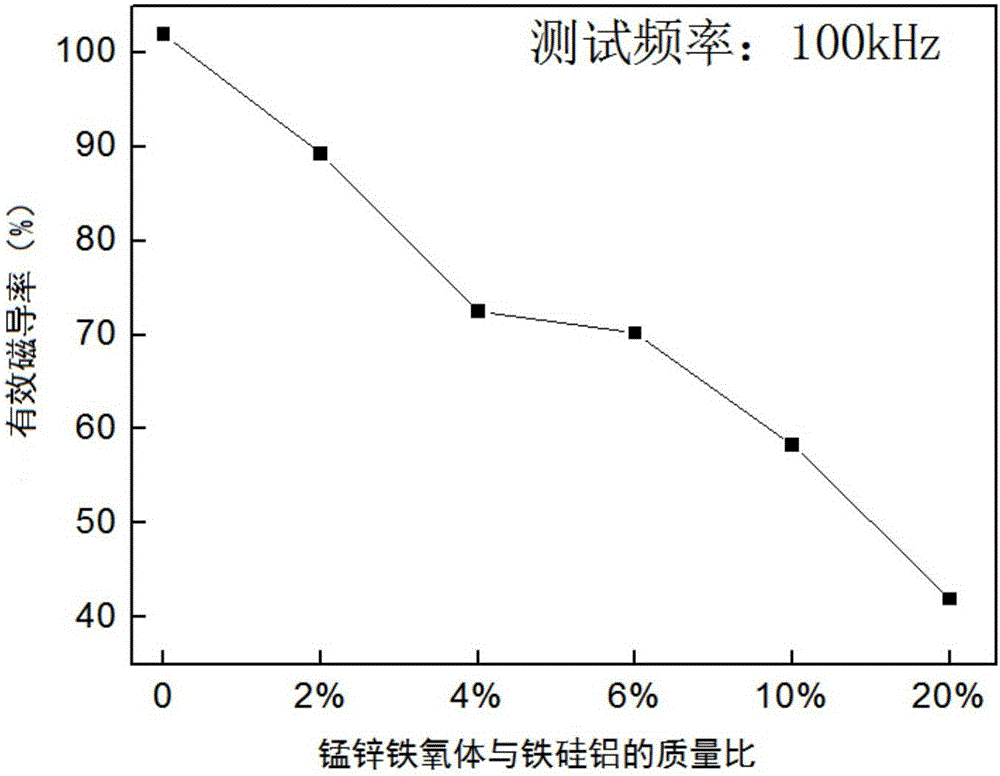

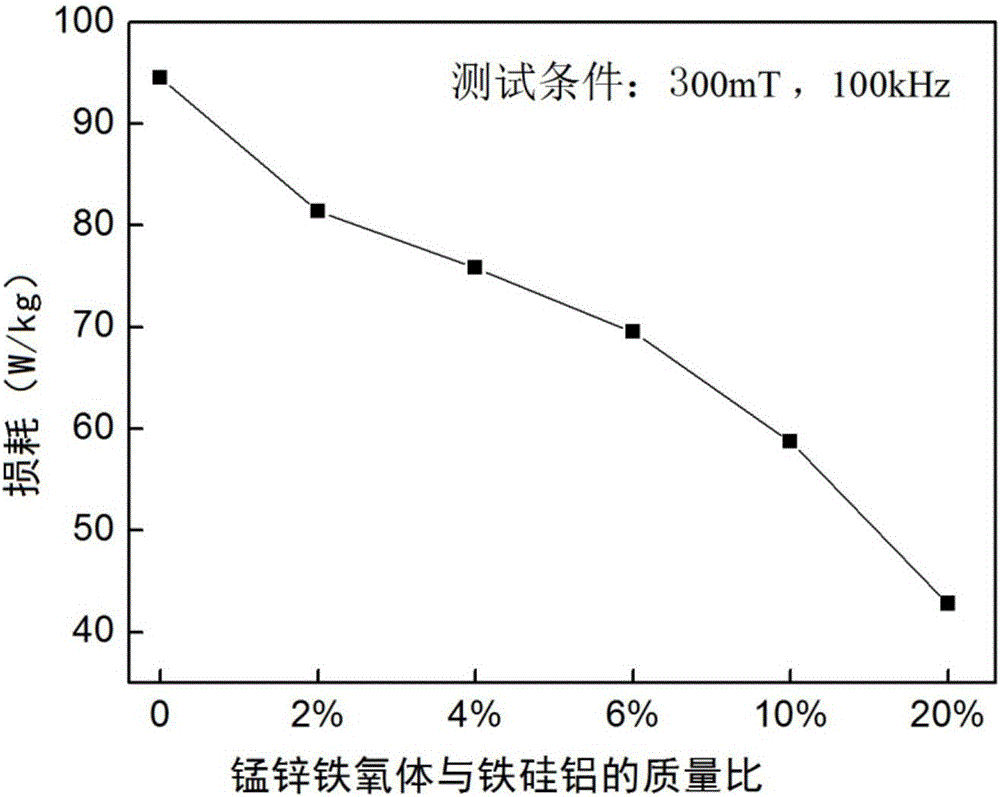

[0061] Referring to the preparation method of Example 1, the mass ratios of manganese-zinc-ferrite powder and sendust-aluminum fragments were sequentially adjusted to 4%, 6%, 10%, and 20%, to prepare composite magnetic powder core products.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Magnetic field strength | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com