Composite soft magnetic material thin film based on sendust soft magnetic material and preparation method thereof

A technology of composite soft magnetic and soft magnetic materials, which is applied in the direction of magnetic materials, inorganic material magnetism, and the application of magnetic films to substrates. It can solve the problems of high processing costs and long time-consuming sputtering molding processes, and reduce processing costs. , enhance process compatibility, and improve the performance of magnetic thin films

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The embodiments of the present invention are described in detail below. This embodiment is implemented on the premise of the technical solution of the present invention, and detailed implementation methods and specific operating procedures are provided, but the protection scope of the present invention is not limited to the following implementation example.

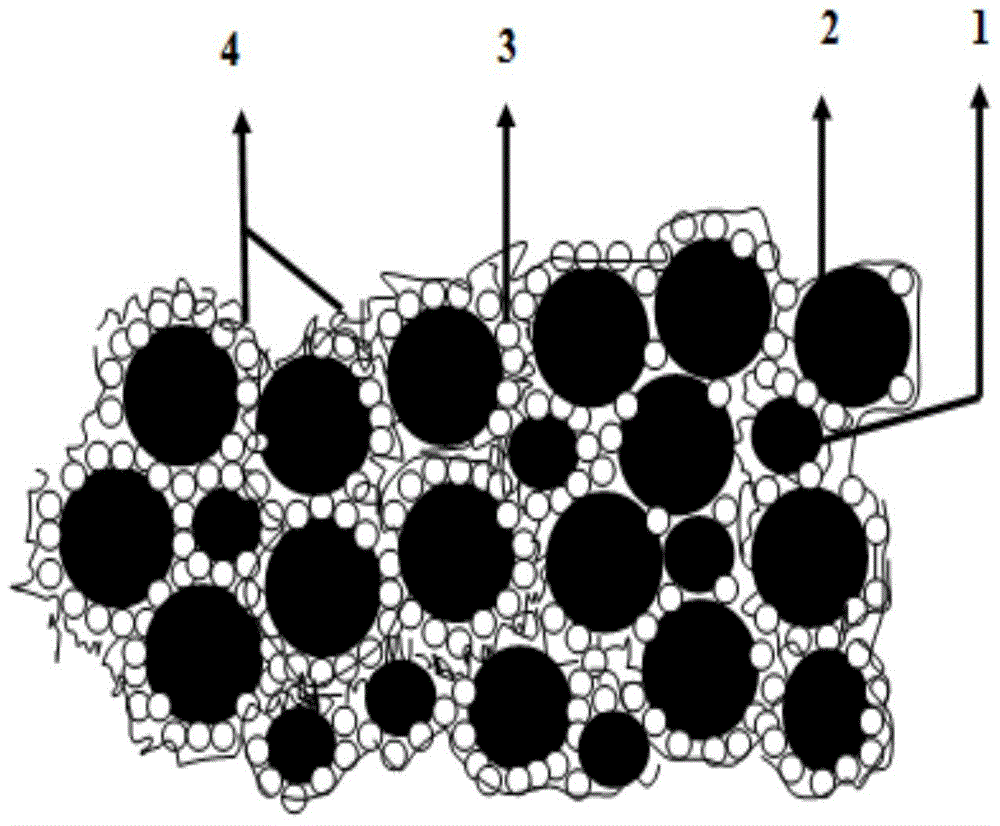

[0022] Such as figure 1 As shown, this embodiment includes: small sendust soft magnetic powder particles 1 , large sendust soft magnetic powder particles 2 , manganese zinc ferrite soft magnetic powder particles 3 , and silica hardened network structure 4 . Manganese zinc ferrite soft magnetic powder particles 3 are used as an insulating agent to coat the surfaces of sendust soft magnetic powder particles 1 and 2, and the particles are bonded by a hardened network structure 4 of silicon dioxide. The gaps between the large sendust soft magnetic powder particles 2 are mainly filled by the sendust soft magnetic powde...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com