Sendust powder integrated pressing inductor and production process thereof

A technology of sendust powder and suppressed inductance, which is applied in the direction of inductance with magnetic core, inductance/transformer/magnet manufacturing, circuit, etc., which can solve the problems of poor temperature characteristics of power induction, unstable electromagnetic performance, and limited application range , to achieve the effect of improving magnetic permeability, solving thermal aging, and good deglue performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] The present invention will be further described below with reference to the accompanying drawings and embodiments.

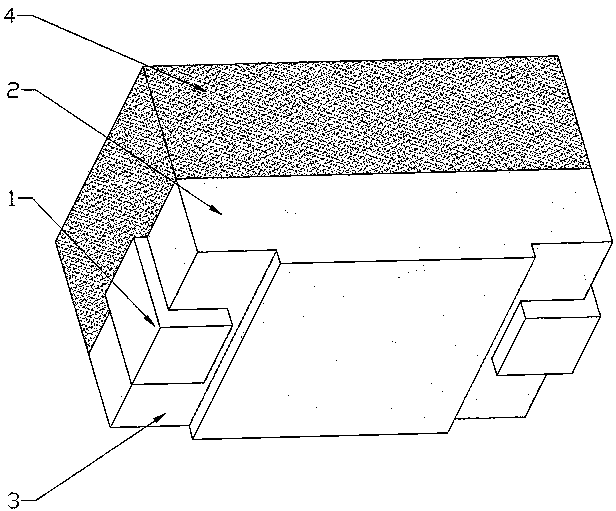

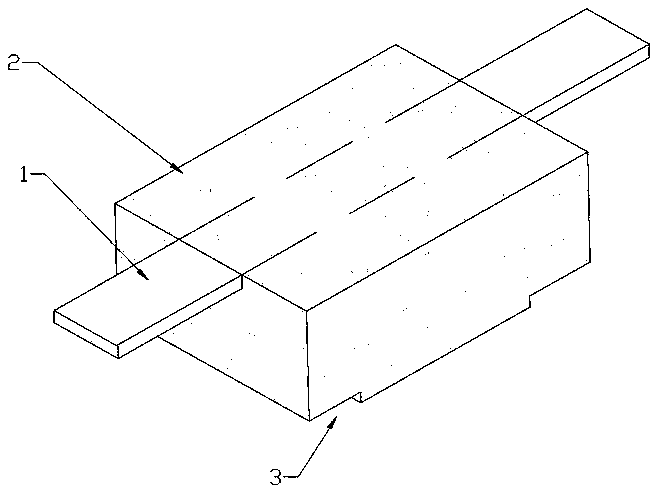

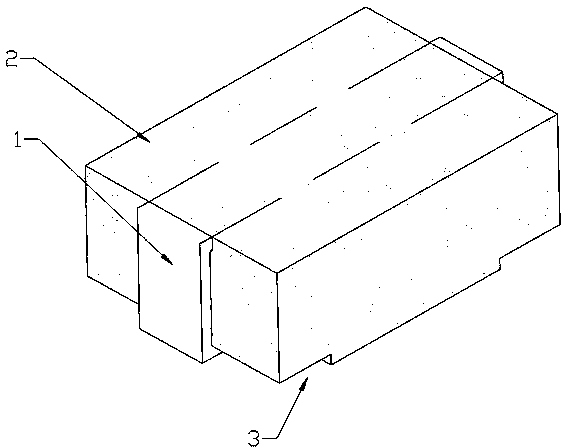

[0023] An iron-silicon-aluminum powder integrated pressing inductor is characterized in that: a red copper strip 1 is used as a coil, the middle part of the red copper strip 1 is wrapped in the iron-silicon-aluminum block 2, and the exposed parts at both ends are welding feet, the surface of which is plated There are nickel and tin; the cross section of the iron-silicon-aluminum block 2 is inverted "convex" shape, so that the shoulder position at the bottom of the iron-silicon aluminum block 2 forms two avoidance spaces 3; the red copper strip 1 The two welding feet are respectively bent down along the side of the iron-silicon-aluminum block 2, and are folded inside the bottom of the iron-silicon aluminum block 2, and the bent parts are correspondingly close to the positions of the above two avoidance spaces 3; The upper surface of the iron-silicon-alumin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com