Method for Industrialized Production of Ferrosilicon Alloy by Carbon Reduction from Senustin Mixed Ore

A technology for ferrosilicon alloy and ferrosilicon, which is applied in the field of industrialized production of ferrosilicon alloy from carbon reduction in ferrosilicon mixed ore, can solve the problem of obtaining qualified iron concentrate and ilmenite concentrate, there is no good way to deal with it, and it is difficult to beneficiation means and other problems, to achieve the effect of high comprehensive recycling rate, significant social and economic benefits, and no environmental pollution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

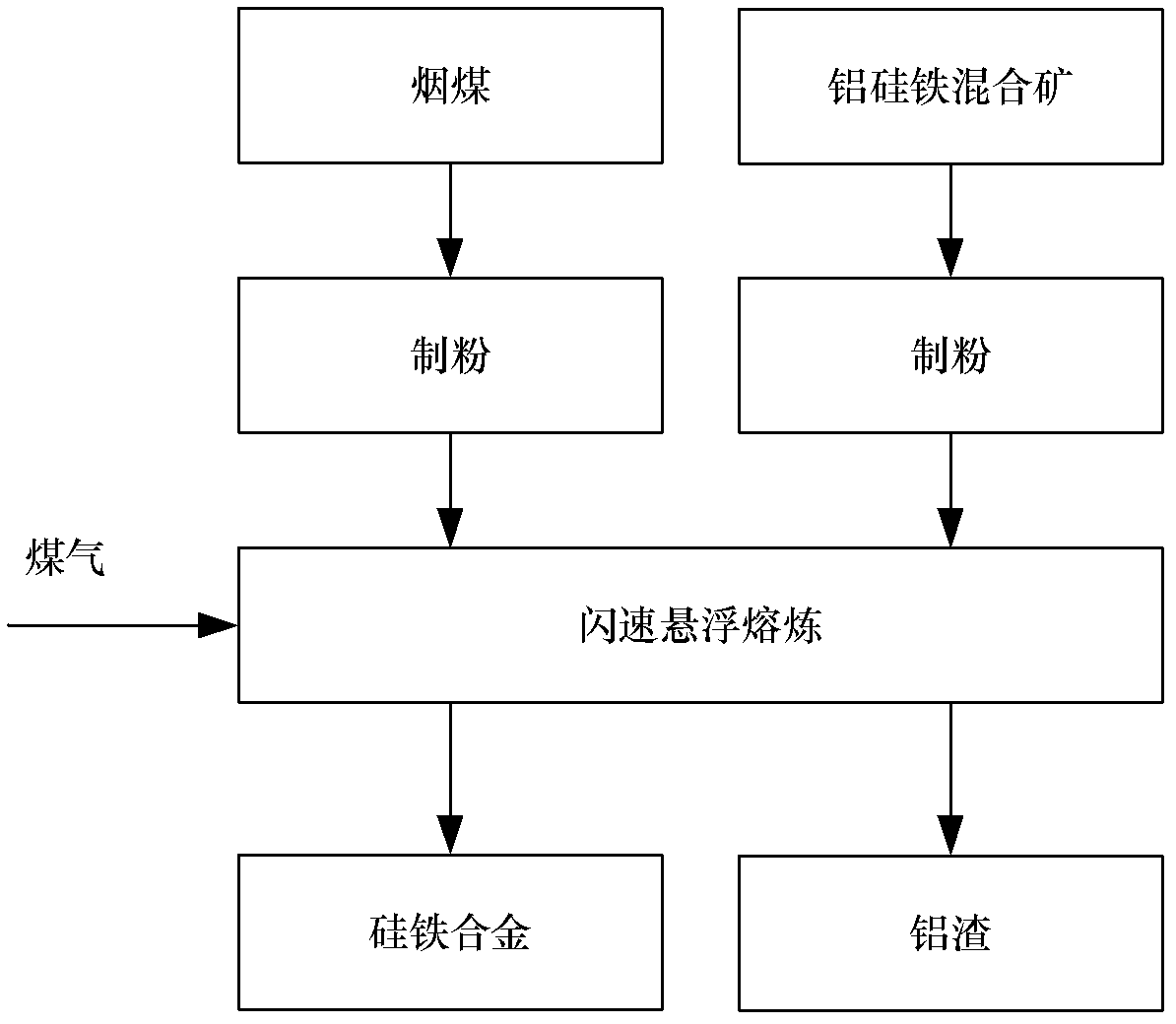

Method used

Image

Examples

Embodiment 1

[0048] Step 1: Preparation of AlSiFe mixed powder

[0049] The sendust mixed ore is crushed mechanically (XMQ-240×90 ball mill) to obtain a sendust mixed powder with a particle size of 280 mesh;

[0050] In the present invention, the main component (mass percentage) of sendustite: aluminum oxide (Al 2 o 3 )19.02%, silicon dioxide (SiO 2 ) 43.21%, total iron (TFe) 10.6%, titanium dioxide (TiO 2 ) 1.82%.

[0051] Step 2: Making Bituminous Coal Powder

[0052] The bituminous coal is crushed mechanically (XMQ-240×90 ball mill) to obtain bituminous coal powder with a particle size of 100 mesh. The main components are: ash 12.64%, volatile matter 20.92%, moisture 3.70%, and fixed carbon 62.74%. The chemical composition of the ash is: 19.52% aluminum oxide, 49.84% silicon dioxide, 6.52% iron oxide, and 11.72% calcium oxide.

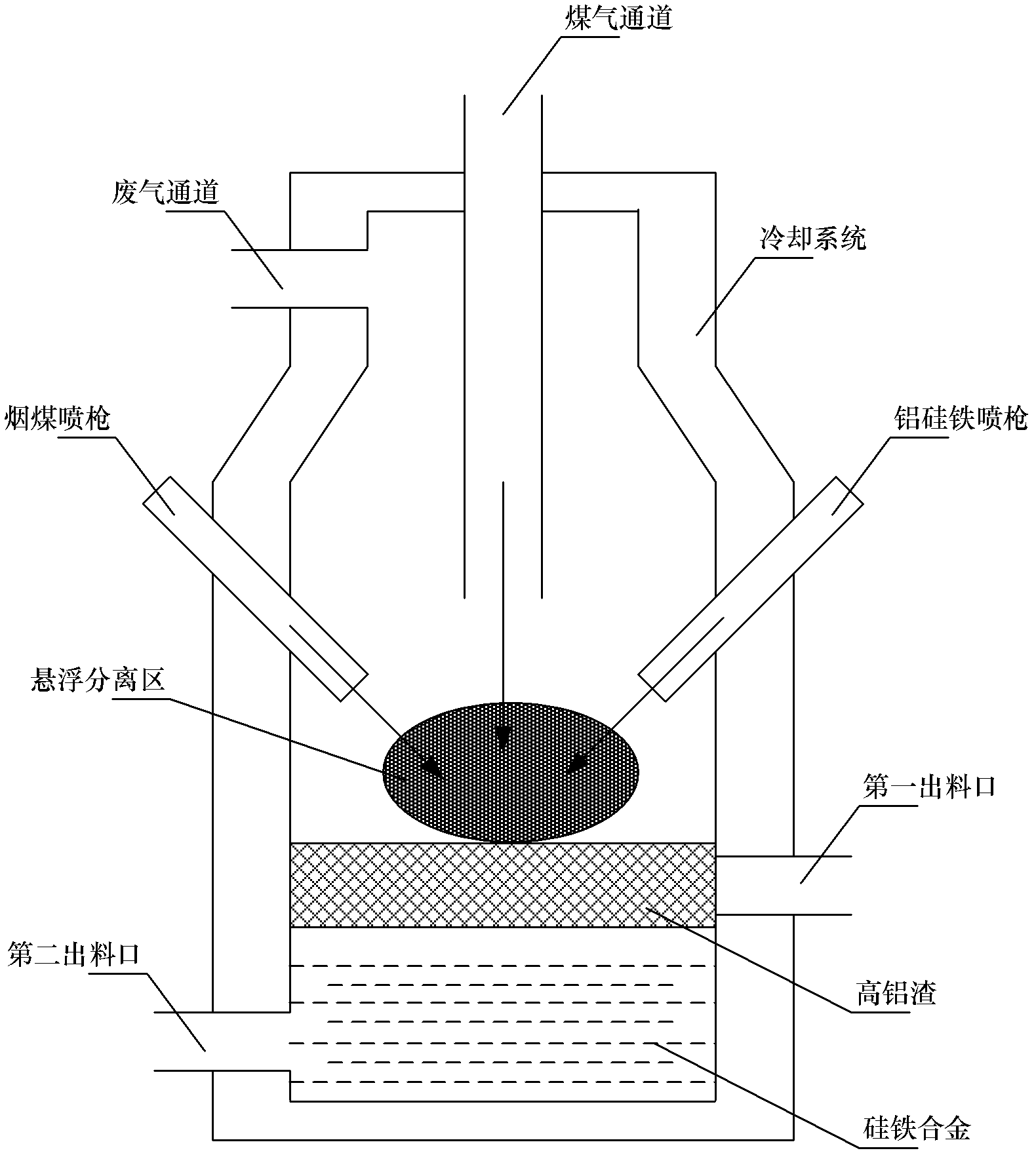

[0053] Step 3: Flash Suspension Reduction and Melting

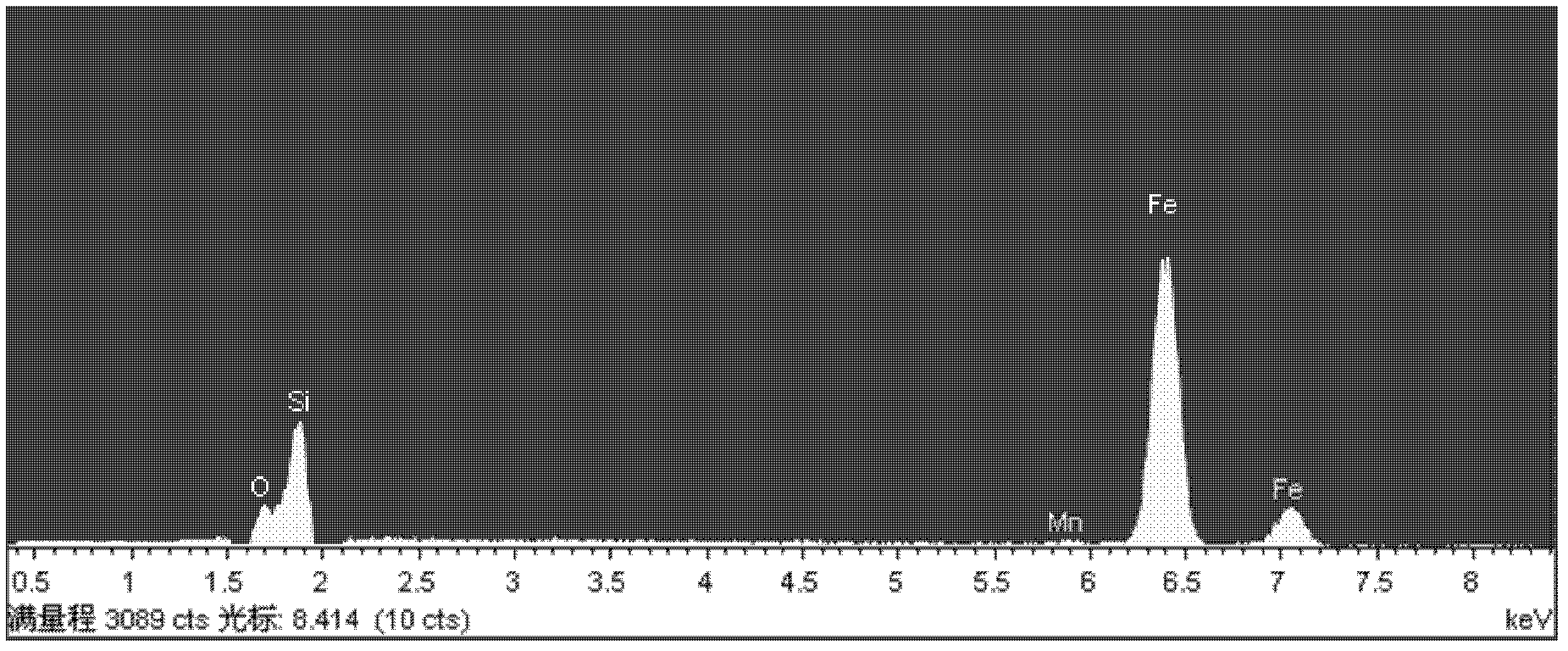

[0054] (A) sendust mixed powder is packed in wherein one spray gun container, regulates this spra...

Embodiment 2

[0062] Step 1: Preparation of AlSiFe mixed powder

[0063] The sendust mixed ore is mechanically crushed to obtain a sendust mixed powder with a particle size of 200 mesh;

[0064] In the present invention, the main component of sendust: aluminum oxide (Al 2 o 3 )19.02%, silicon dioxide (SiO 2 ) 43.21%, total iron (TFe) 10.6%, titanium dioxide (TiO 2 ) 1.82%.

[0065] Step 2: Making Bituminous Coal Powder

[0066] The bituminous coal is mechanically crushed to obtain bituminous coal powder with a particle size of 80 meshes. The main components are: 12.64% ash, 20.92% volatile matter, 3.70% moisture, and 62.74% fixed carbon. The chemical composition of the ash is: 19.52% aluminum oxide, 49.84% silicon dioxide, 6.52% iron oxide, and 11.72% calcium oxide.

[0067] Step 3: Flash Suspension Reduction and Melting

[0068] (A) the sendust mixed powder is packed in one of the spray gun containers, the spray gun pressure is adjusted under 3MPa, the sendust mixed powder is inject...

Embodiment 3

[0076] Step 1: Preparation of AlSiFe mixed powder

[0077] The sendust mixed ore is crushed by mechanical crushing to obtain the sendust mixed powder with a particle size of 400 mesh;

[0078] In the present invention, the main component of sendust: aluminum oxide (Al 2 o 3 )19.02%, silicon dioxide (SiO 2 ) 43.21%, total iron (TFe) 10.6%, titanium dioxide (TiO 2 ) 1.82%.

[0079] Step 2: Making Bituminous Coal Powder

[0080] The bituminous coal is mechanically crushed to obtain bituminous coal powder with a particle size of 120 meshes. The main components are: 12.64% ash, 20.92% volatile matter, 3.70% moisture, and 62.74% fixed carbon. The chemical composition of the ash is: 19.52% aluminum oxide, 49.84% silicon dioxide, 6.52% iron oxide, and 11.72% calcium oxide.

[0081] Step 3: Flash Suspension Reduction and Melting

[0082] (A) sendust mixed powder is packed in wherein one spray gun container, regulates this spray gun pressure under 3MPa, makes sendust mixed powder...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Granularity | aaaaa | aaaaa |

| Granularity | aaaaa | aaaaa |

| Granularity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com