Novel thermal insulation and heat preservation structure for complex building and construction technique

A technology of thermal insulation and thermal insulation layer, applied in building components, building structure, thermal insulation, etc., can solve problems such as falling off, hollow tiles, cracks, etc., achieve high durability and strength, save raw materials, and reduce costs Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

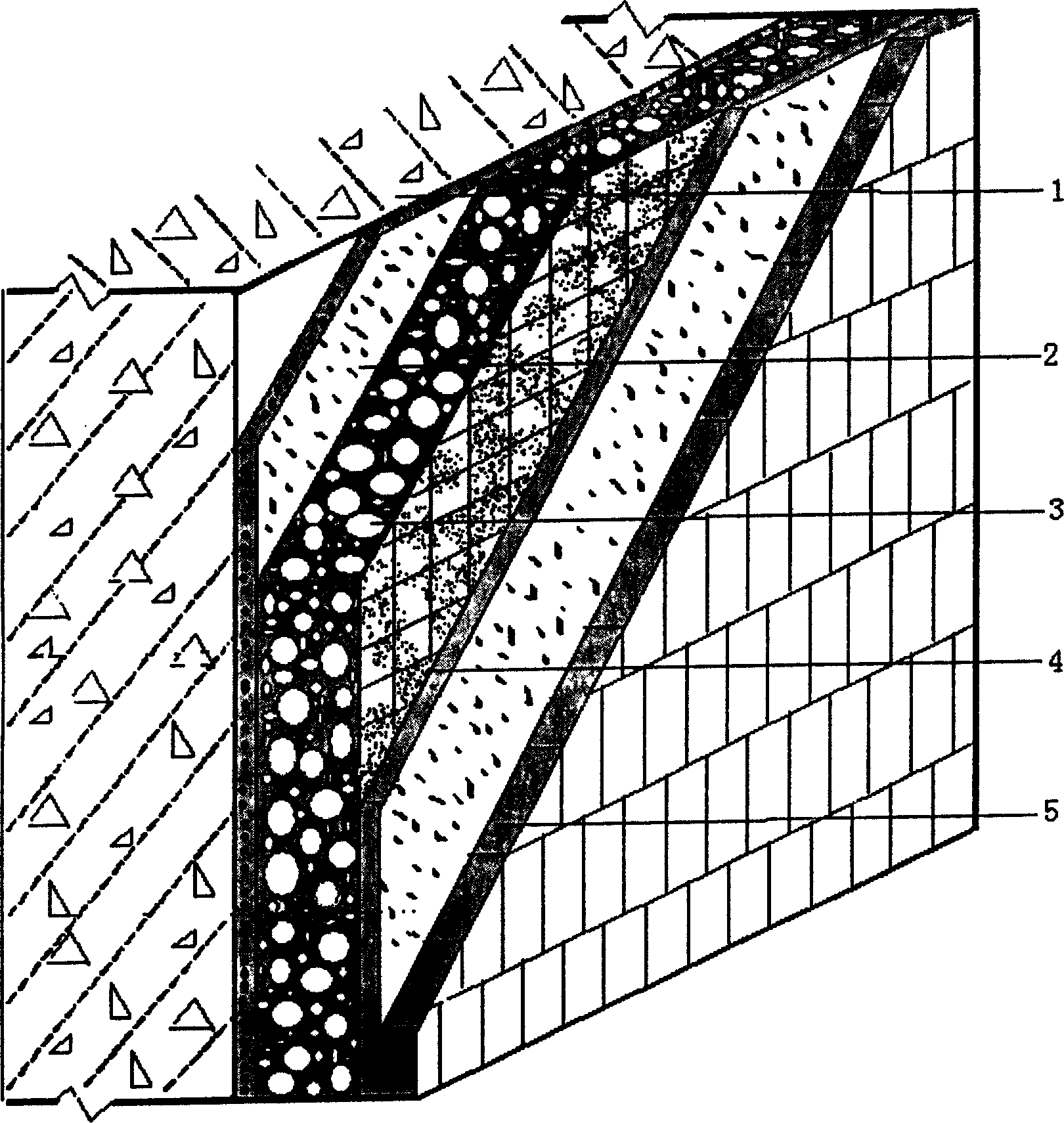

[0020] A new type of composite building heat insulation structure, the heat insulation structure has a building matrix, a heat insulation layer, a reinforced anti-crack layer, and a heat reflection decorative layer from the inside to the outside. Material A and polystyrene foam particles B are composed of two parts, the composite dry powder material A is composed of 60% cement, and the specific surface area is 400-5000m 2 / kg silica-alumina glass hollow sphere material 35%, air-entraining agent 0.05%, modifier%, water reducing agent 0.95%, fiber 2%, tackifier 2%, reinforced anti-crack layer is made of hot-dip galvanized steel mesh and Fiber-reinforced polymer modified anti-cracking matrix is coagulated. The components and weight content of the anti-cracking matrix are: 1 part of anti-cracking rubber powder, 2.5 parts of cement, 12 parts of sand, 2.5 parts of water, and the composition of anti-cracking rubber powder Parts and weight content: inorganic mineral powder 40%, alka...

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com