Directly driving screw pump device

A technology for driving screw and pump devices, which is applied in the direction of pumps, axial flow pumps, non-variable pumps, etc. It can solve the problems of damage to the reduction box, mechanical loss, and large volume, so as to eliminate oil leakage and reduce oil production costs. , the effect of reducing the volume

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

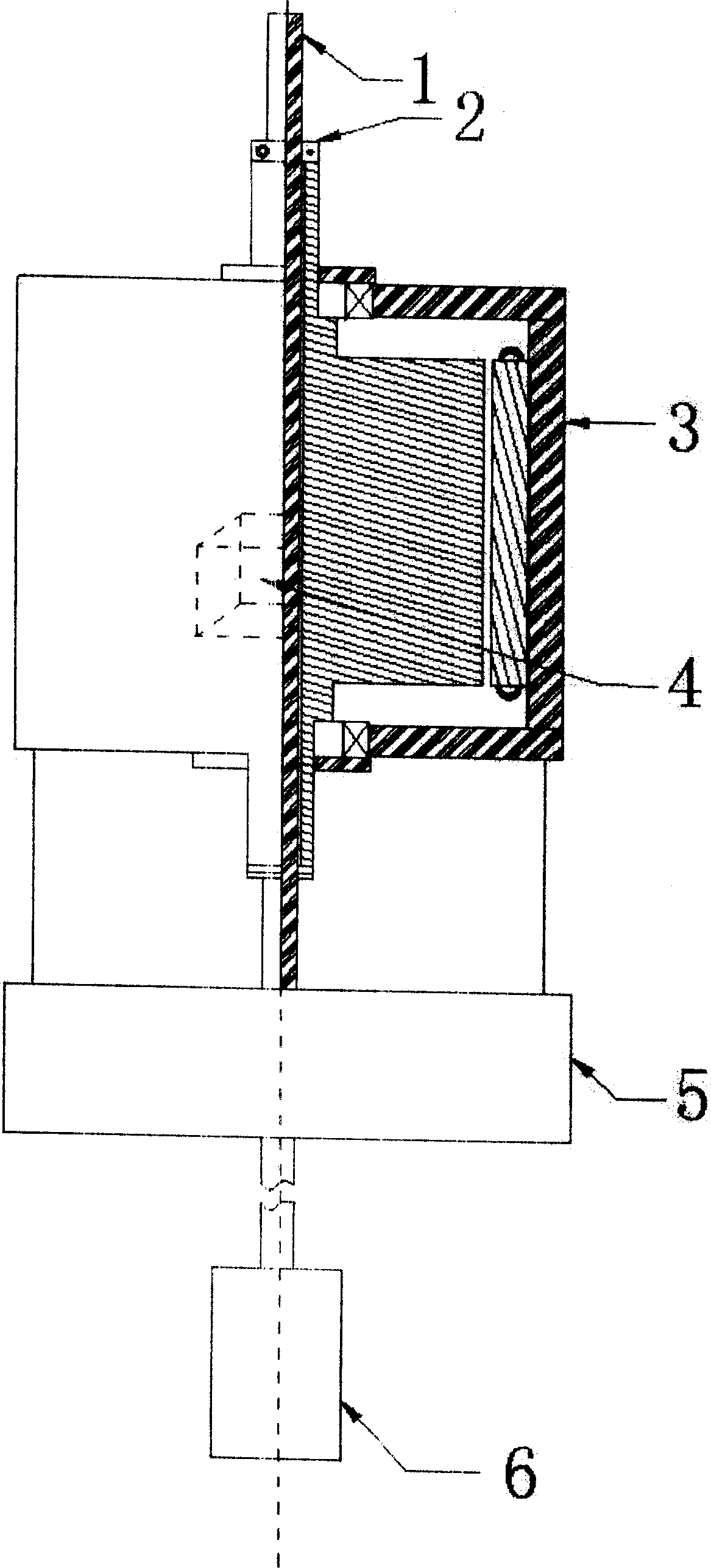

[0010] As shown in Figure 1, the fixed seat 5 is the basic installation base, the low-speed motor 3 is installed on the fixed seat 5, the motor controller is directly installed inside the low-speed motor 3, and the output line of the motor controller is connected to the incoming line of the low-speed motor 3 , the incoming line of the motor controller is connected to the power grid. The polished rod 1 passes through the hollow shaft of the low-speed motor 3 and the center of the fixing seat 5. The polished rod 1 is fixedly connected with the hollow shaft of the low-speed motor 3 through the coupling 2. Connected with the output shaft of the low-speed motor 3, the screw pump body 6 is at the lowest end of the device.

[0011] The rotating shaft of the low-speed motor 3 is a hollow structure, and is vertically placed on the holder 5 . The motor controller is used in conjunction with the low-speed motor 3, and the low-speed motor 3 outputs a lower speed under the control of the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com