Magnetic spring induction type reciprocating motion counter

A reciprocating motion, reed sensor technology, used in engine components, engine lubrication, lubricating parts, etc., can solve problems such as the oil supply at the lubrication point being lower than the design value, the machining error of the connecting rod, and the assembly error of the piston rod. Achieve the effect of improving convenience, fewer assembly parts, and avoiding dynamic seal design

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

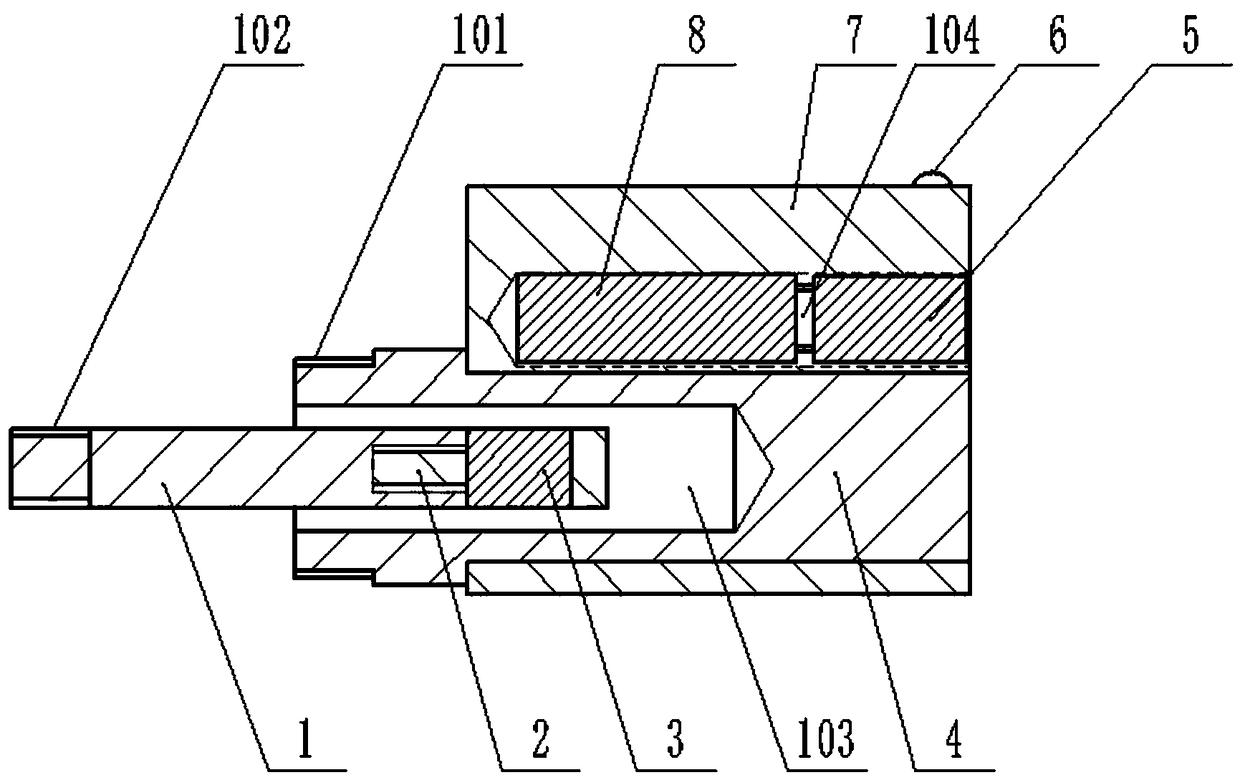

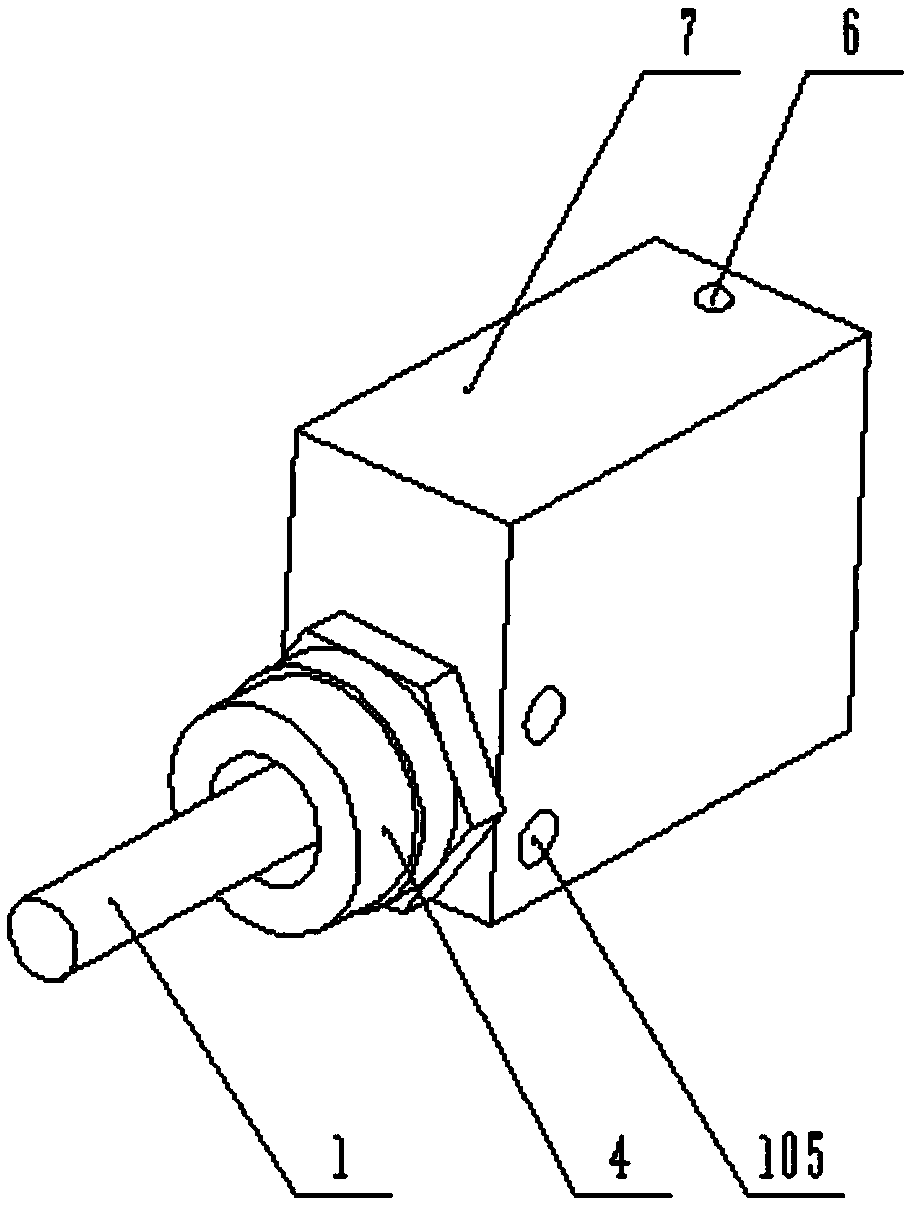

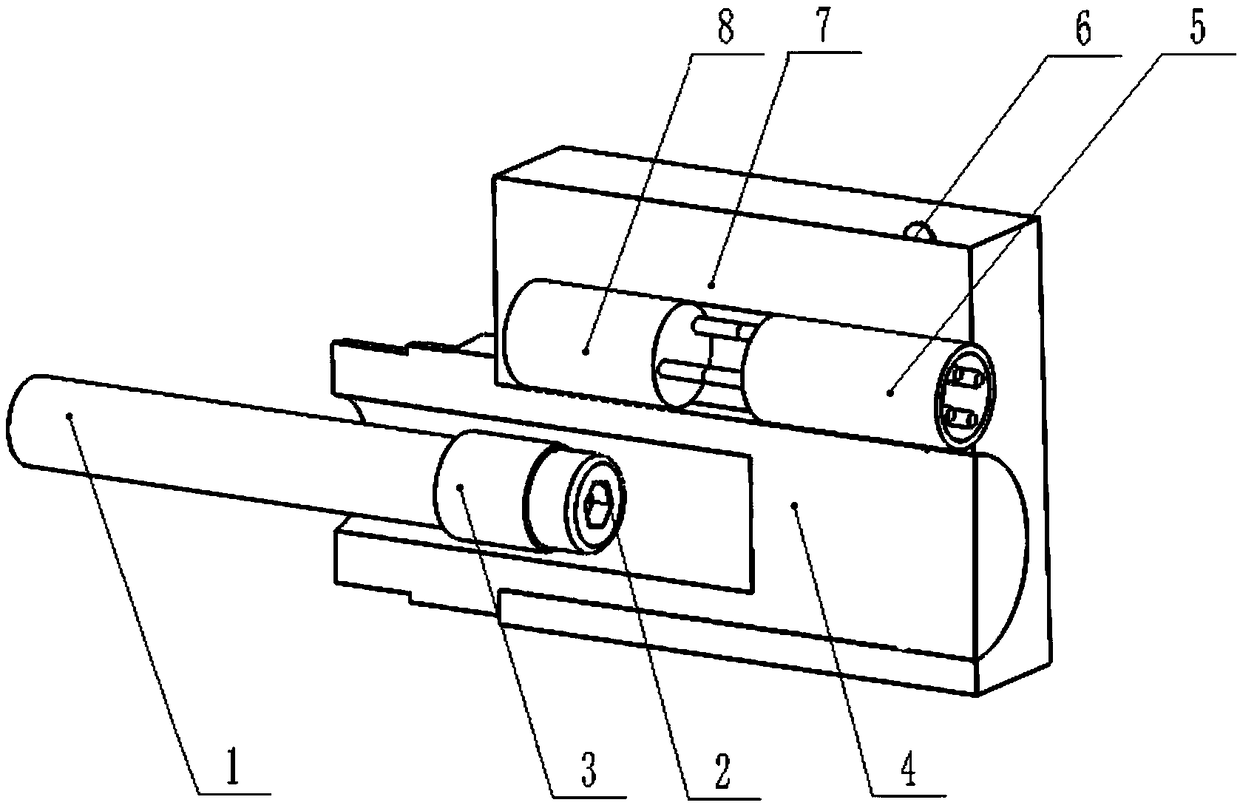

[0019] The main structure of the magnetic reed induction type reciprocating motion counter described in this embodiment includes a connecting rod 1, a bolt 2, a ring magnet 3, a connecting sleeve 4, an aviation plug 5, an indicator light 6, a casing 7, a magnetic reed sensor 8, a connecting sleeve External thread 101, connecting rod external thread 102, connecting sleeve cavity 103, reed sensor mounting hole 104, housing fixing thread 105, housing connecting sleeve mounting hole 106;

[0020] The left end of the cylindrical connecting rod 1 is connected with the piston rod in the progressive distributor, and the right end of the connecting rod is covered with a ring magnet 3, which is arranged on the right side of the ring magnet 3 to support and prevent the ring magnet 3 from connecting rod 1. Bolt 2 that slides down, the ring magnet 3 can reciprocate with the piston rod in the progressive oil volume distributor, the upper part of the ring magnet 3 is provided with a reed sens...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com