A non-contact reciprocating rotary motion counter

A rotary motion and counter technology, which is applied to engine components, engine lubrication, signal processing, etc., can solve the problems of large movement resistance of cylindrical magnets, limited service life, and processing errors of connecting rods, so as to save replacement man-hours and costs , improve the convenience of maintenance, and avoid the effect of dynamic seal design

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

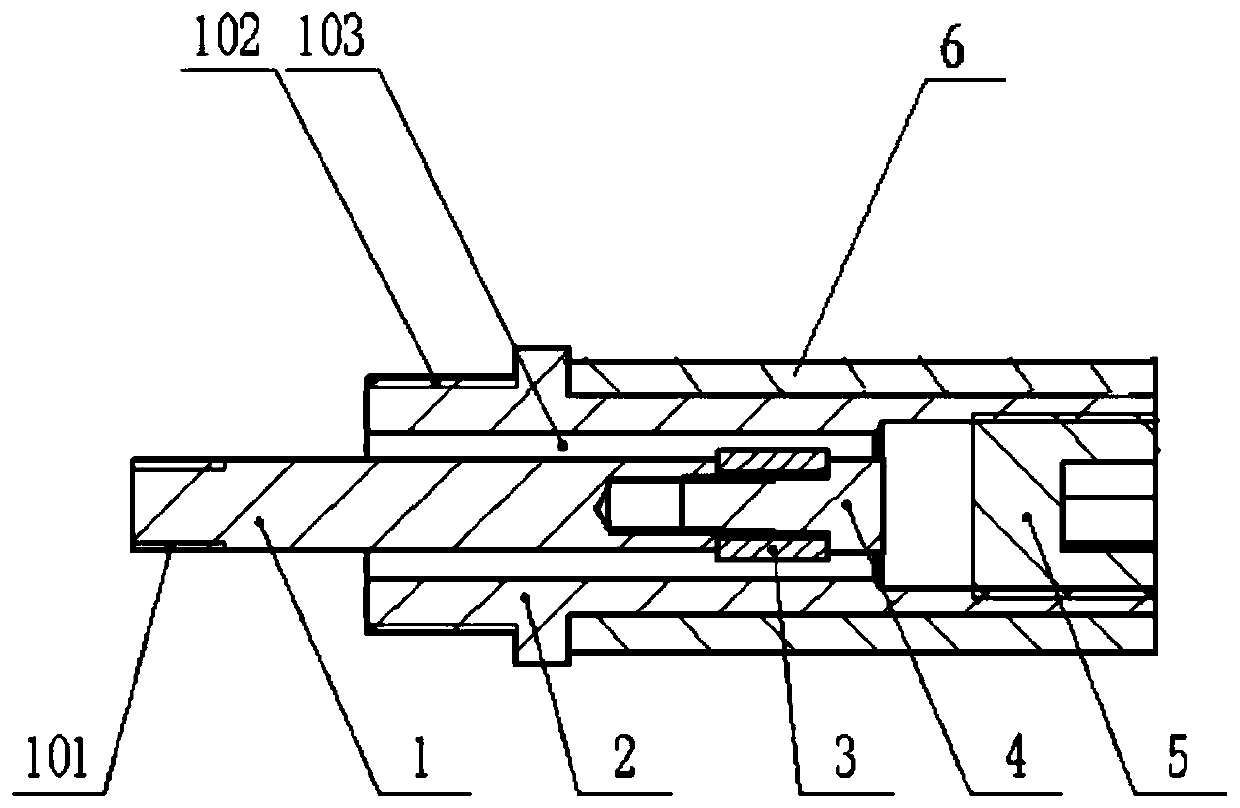

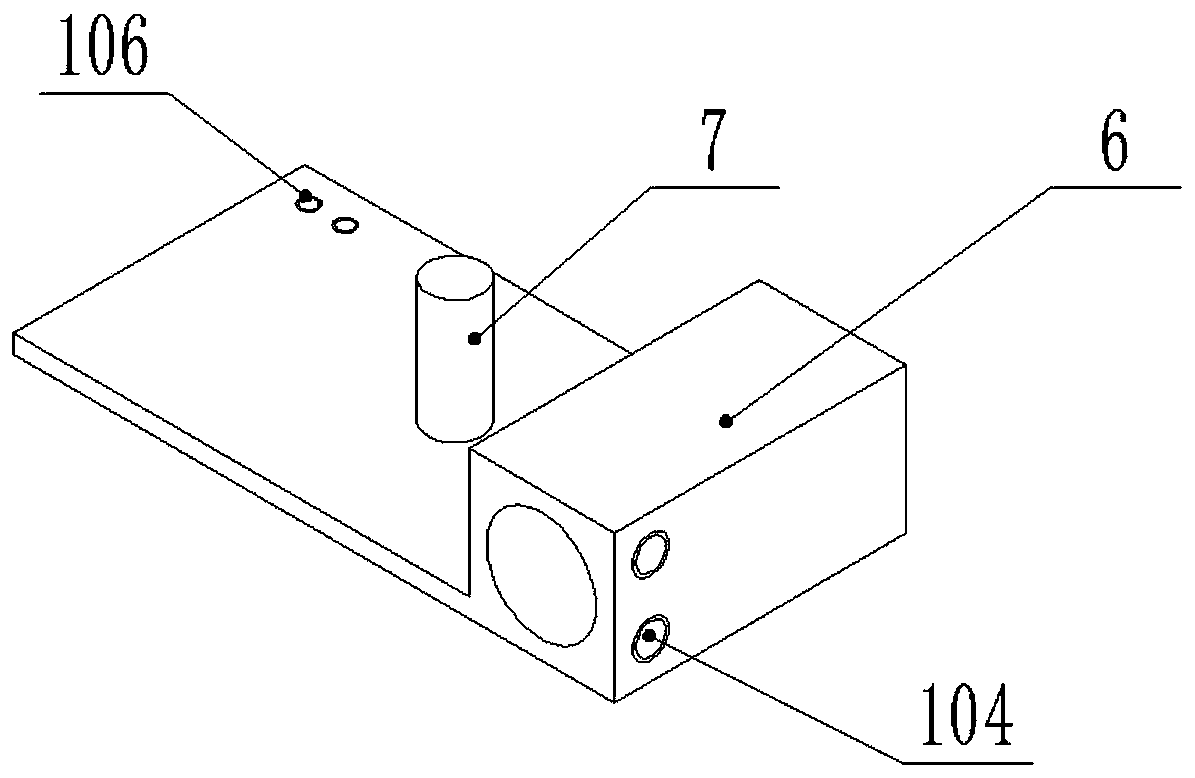

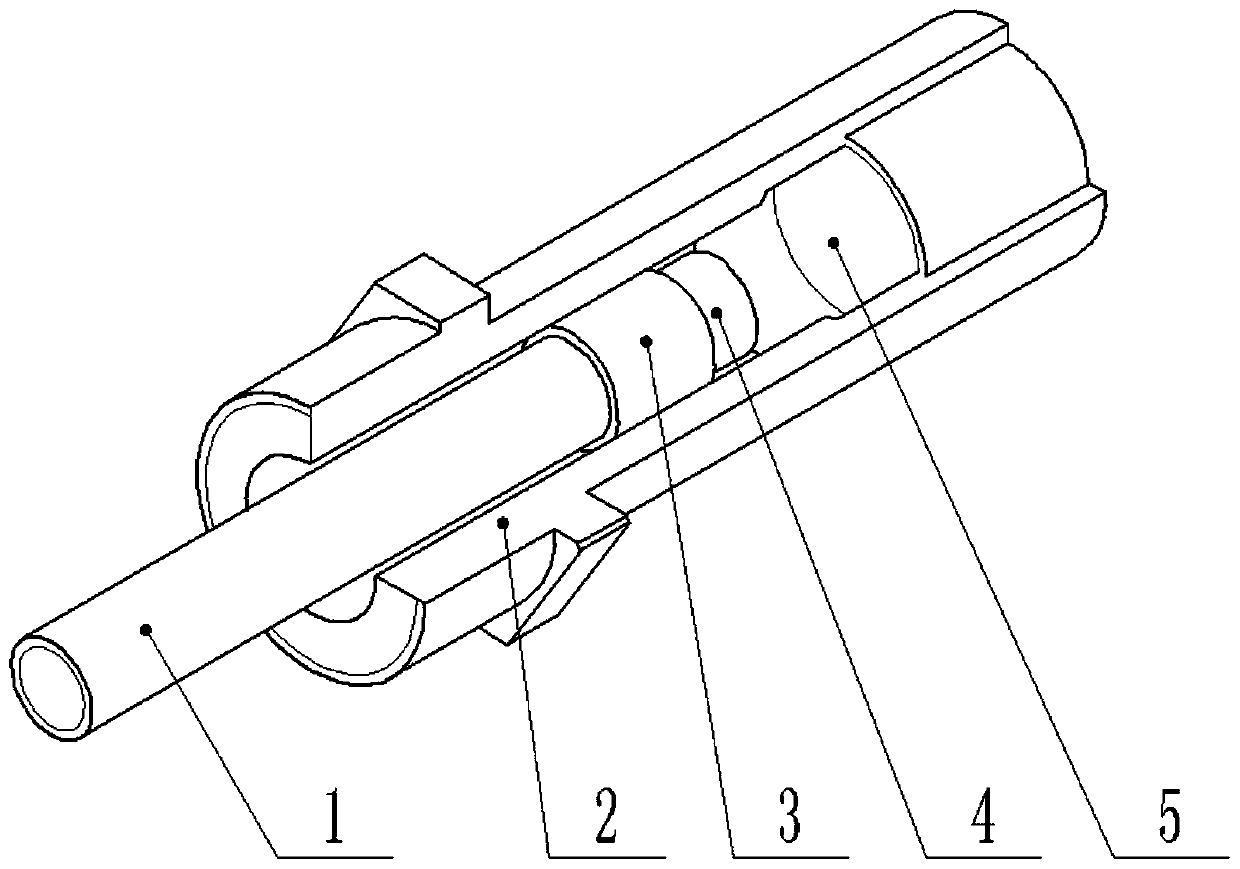

[0017] The main structure of the non-contact reciprocating motion counter described in this embodiment includes a connecting rod 1, a connecting sleeve 2, an annular magnet 3, a bolt 4, a plug 5, a housing 6, a short shaft 7, a cylindrical magnet 8, and a bearing 9 , photoelectric sensor 10, rectangular baffle 11, bearing sleeve 12, connecting rod external thread 101, connecting sleeve external thread 102, connecting sleeve cavity 103, housing fixing thread 104, square groove 105; cylindrical connecting rod 1 outer sleeve There is a connecting sleeve 2 with a hollow cylindrical structure, and the connecting rod 1 can move left and right along the axial direction of the connecting sleeve 2. The left end of the connecting rod 1 extends out of the connecting sleeve 2 and is connected with the piston rod in the progressive distributor. The piston rod can drive the connecting rod 1 to reciprocate left and right. The right end of the connecting rod 1 is covered with a ring magnet 3. ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com