Back-contact solar battery and manufacturing method thereof

A solar cell and back-contact technology, applied in the field of solar cells, can solve problems such as difficulty in popularization, incompatibility, and environmental pollution by waste, and achieve simple, reasonable, safe and reliable processes, improve fill factor and short-circuit current, and eliminate current-carrying Effects of sub-transverse transmission losses and electrode shadowing effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

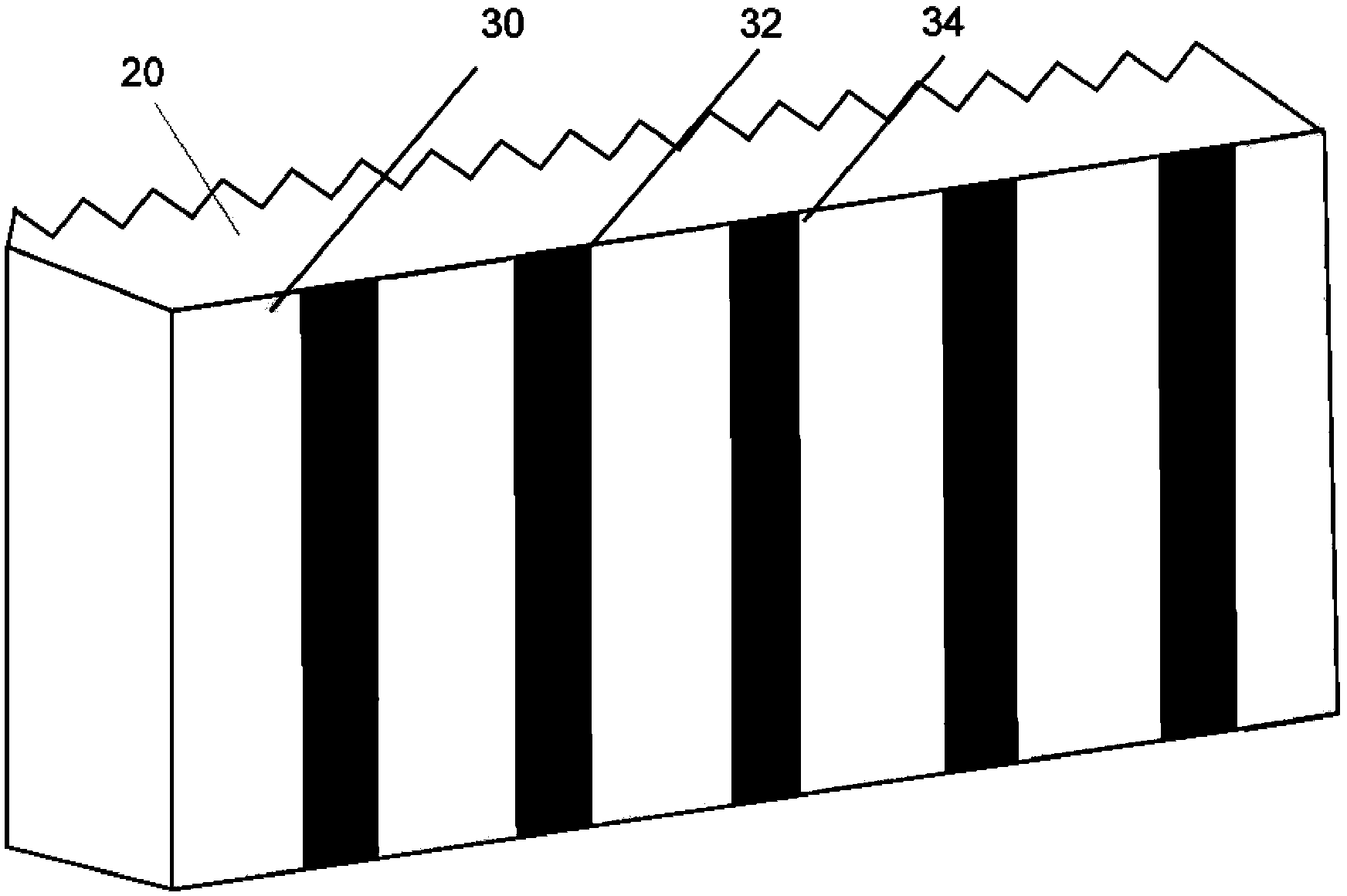

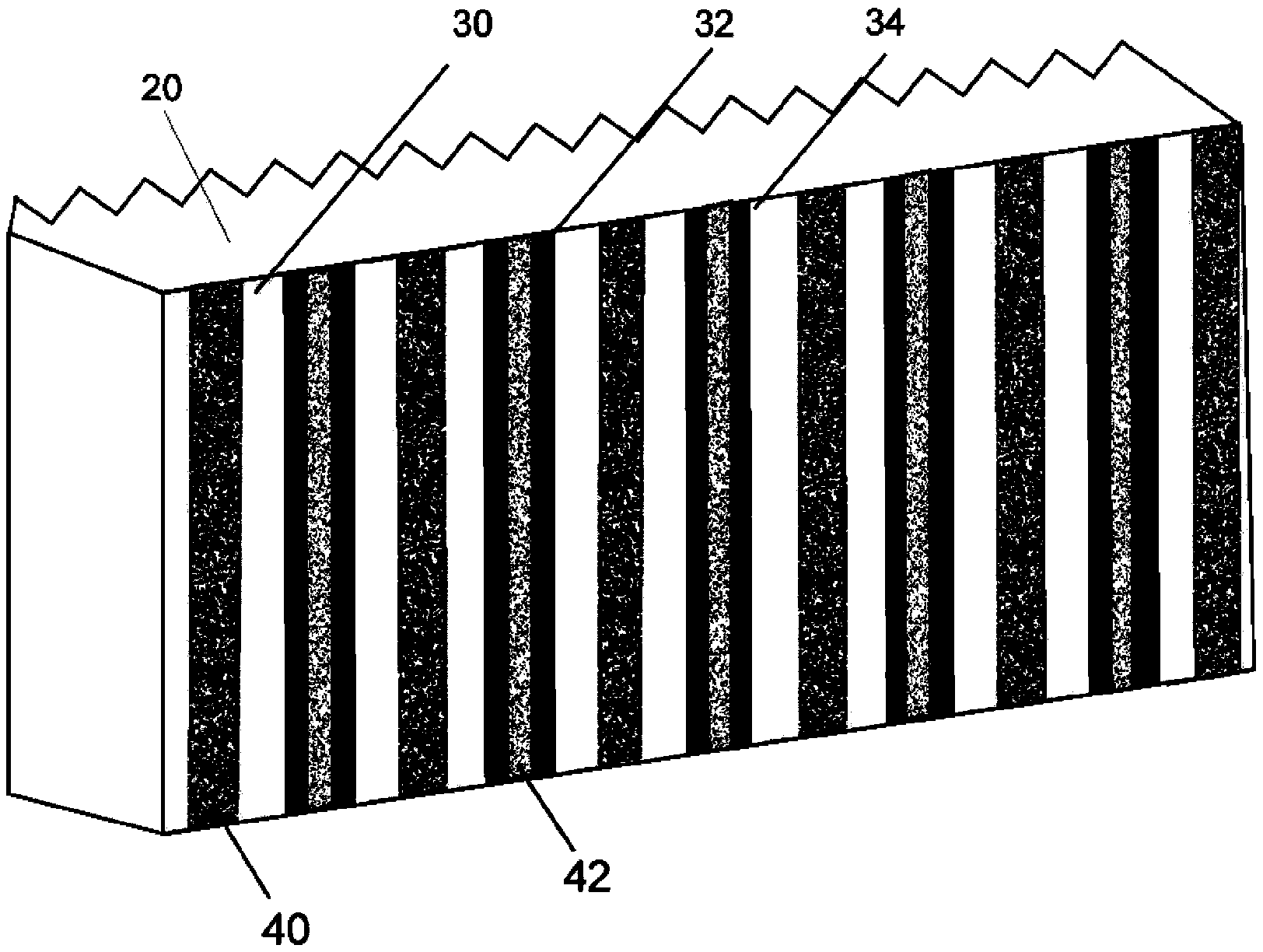

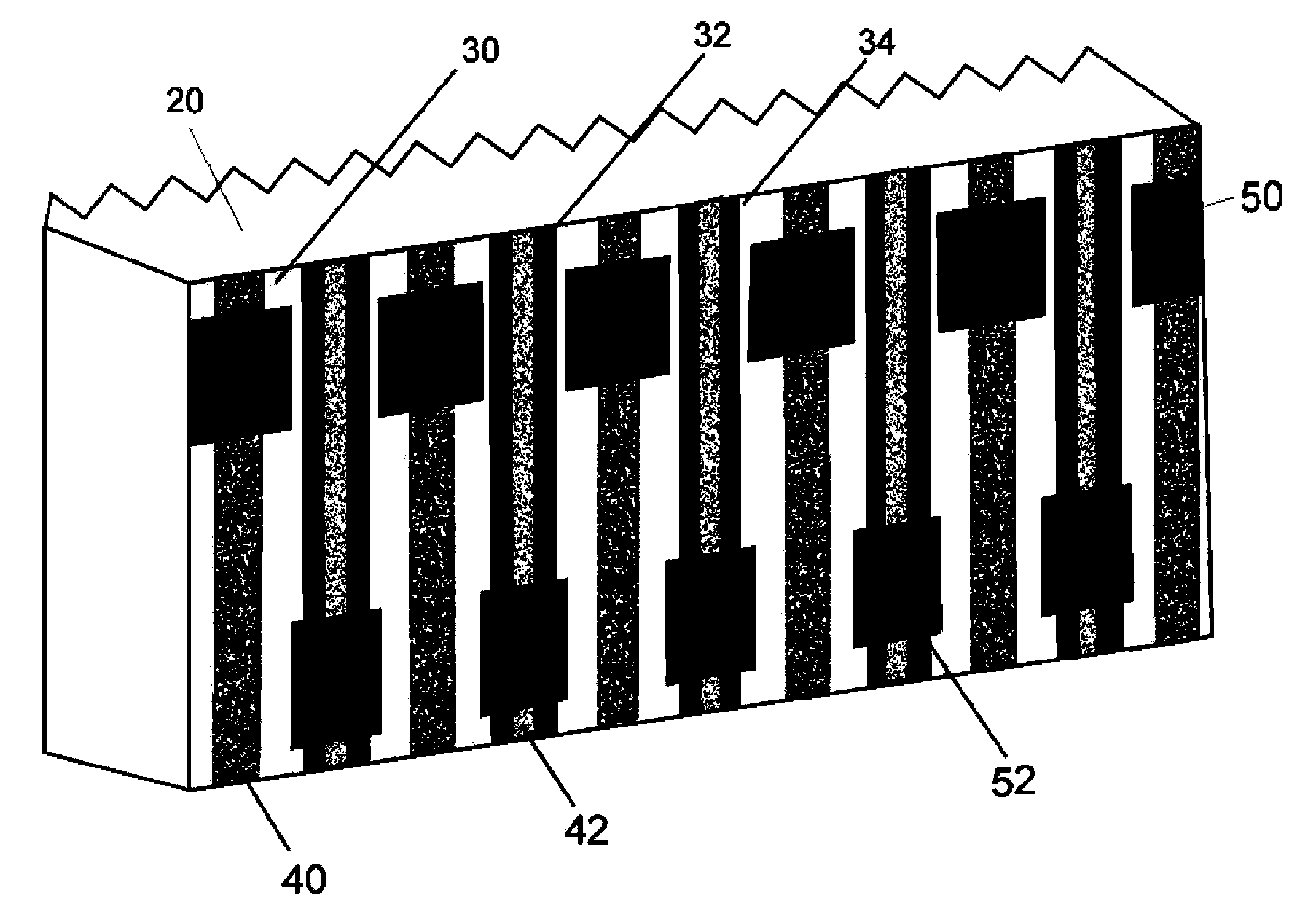

[0037] Such as Figure 4 As shown in , the back contact solar cell provided by this embodiment includes an N-type single crystal silicon substrate silicon substrate 20, a p+ doped region 30 and an n+ doped region 32 arranged on the back side of the silicon substrate, and a p+ doped region 30 and an n+ doped region. The doped regions 32 are alternately arranged on the back side of the silicon substrate 20, the p+ doped region 30 is provided with a positive electrode contact fine grid 40, and the n+ doped region 32 is provided with a negative electrode contact fine grid 42, and on the back side of the silicon substrate 20 A positive electrode main grid 60 and a negative electrode main grid 62 are also provided. An insulating barrier layer 50 is provided at the contact position between the positive electrode main grid 60 and the negative electrode contact fine grid 42 and the n+ doped region 32 where it is located. The grid 60 is located on the insulating barrier layer 50 and is ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com