A steel structure modular prefabricated tooling

A modular and steel structure technology, applied in building construction, construction, building material processing, etc., can solve the problems of large demand for materials, laborious process, low work efficiency, etc., and achieve complete functions, flexible operation and high work efficiency Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0035] The present invention will be described in detail below in conjunction with the accompanying drawings and specific embodiments.

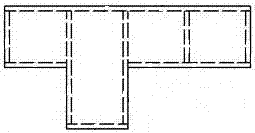

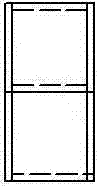

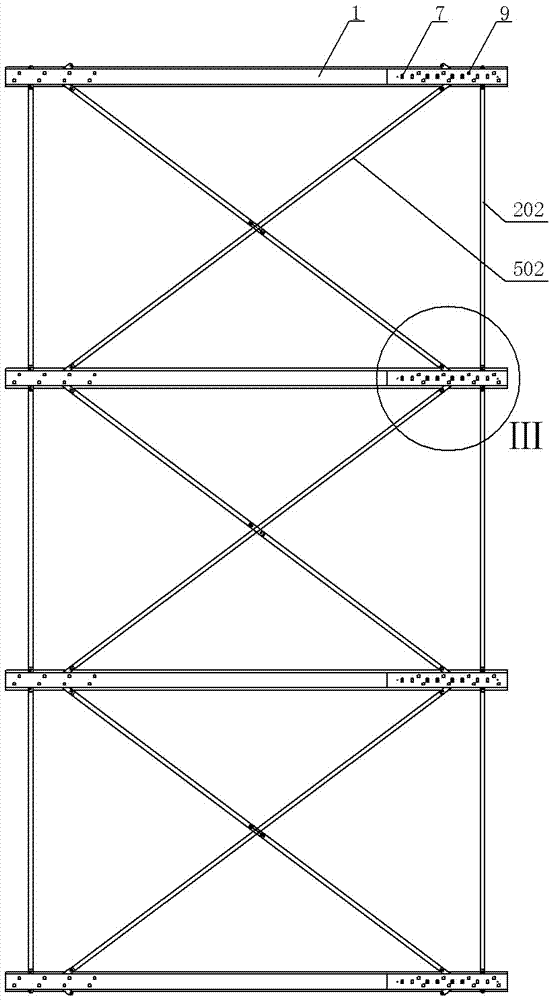

[0036]The specific structure of an embodiment of the present invention is as Figure 1 to Figure 9 As shown, the steel structure modular prefabricated tooling of this embodiment includes at least two sets of bracket systems arranged in parallel and at intervals and tie rods connecting two adjacent sets of bracket systems together. The tie rods include vertical tie rods 502 and diagonal tie rods 202, The vertical tie rod 502 is arranged perpendicular to the support system, and the diagonal stay rod 202 has an included angle of 0-90° with the support system. Each group of support systems includes a base plate 3, a lower profile steel 2 and an upper profile steel 1 arranged sequentially from bottom to top, and a horizontal adjustment mechanism is fixedly connected between the upper profile steel 1 and the lower profile steel 2, and the horizonta...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com