Cast-in-situ floor filled with special necking netted box-shaped cavity component

A box-shaped cavity, hollow floor technology, applied in building components, floor slabs, building structures, etc., can solve the problems of reducing construction production efficiency, slowing down the progress of the project, blocking troubles, etc. The effect of improving quality and construction efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0045] The technical solutions of the present invention will be clearly and completely described below in conjunction with the accompanying drawings in the present invention.

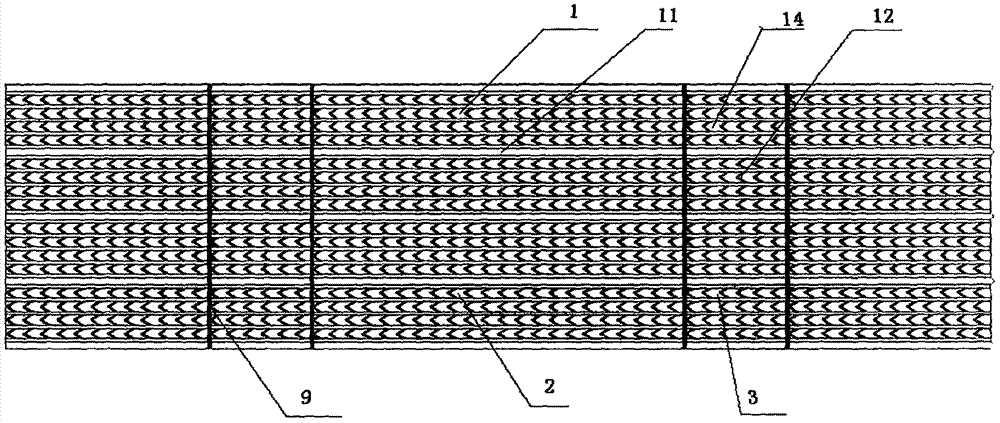

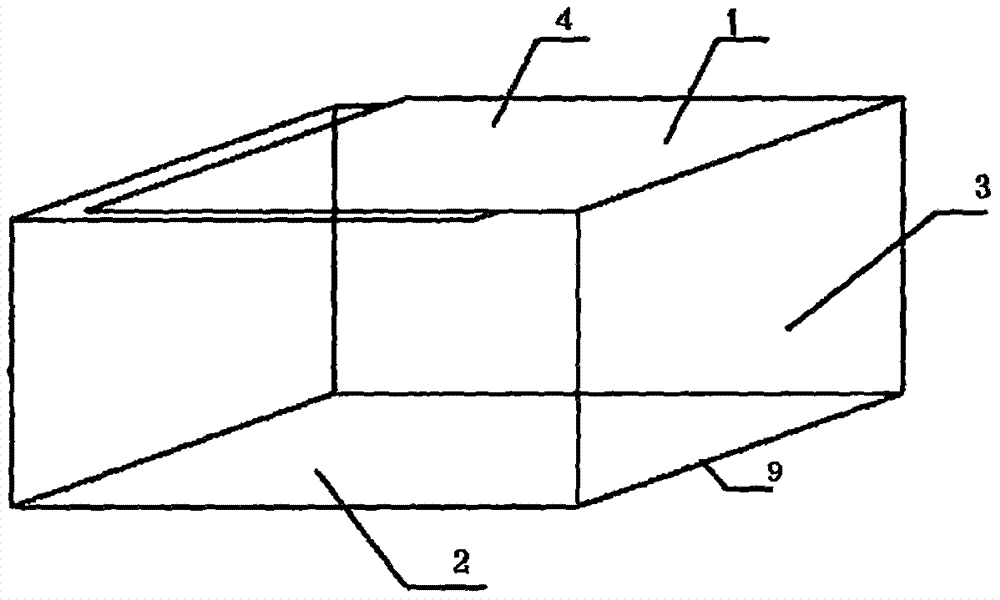

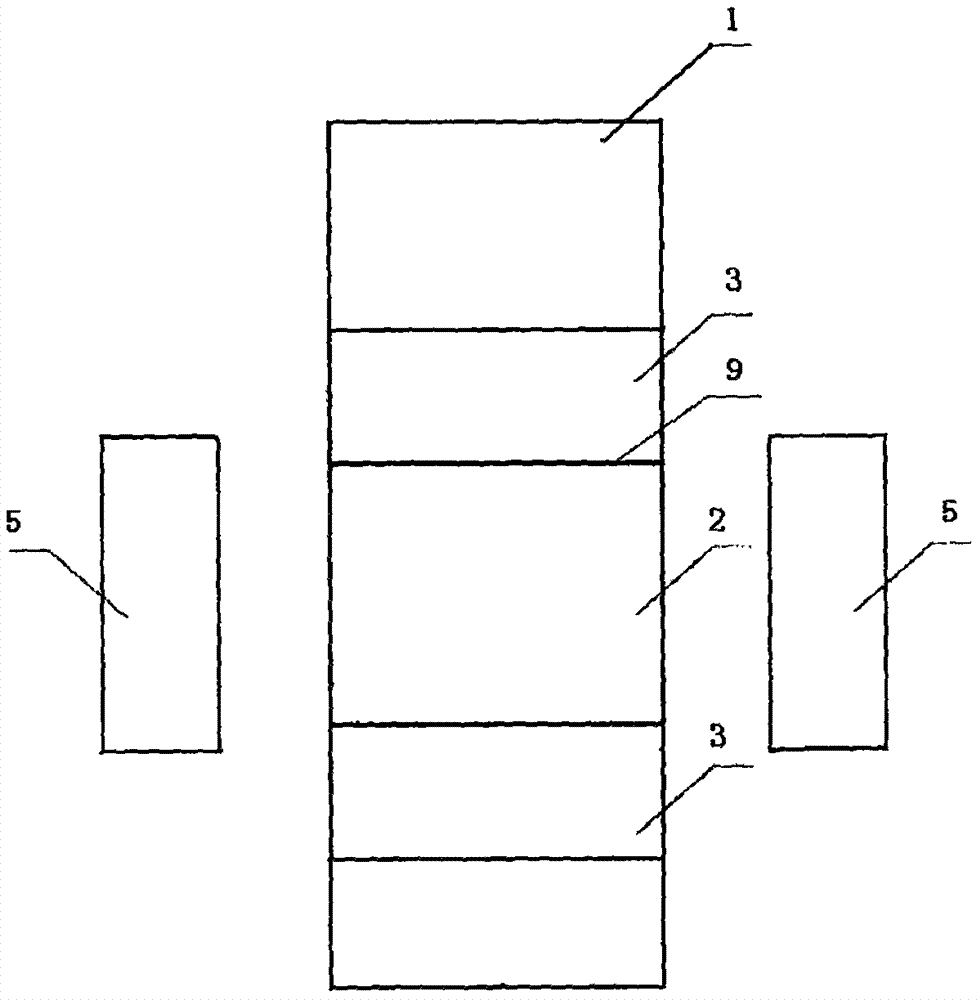

[0046] figure 1 and figure 2 Respectively, the plan view of the special closing net used in the special closing net box-shaped cavity member of the present invention and the schematic diagram of the main body of the special closing net box-shaped cavity member formed by folding the special closing net, as figure 1 As shown, the special closing mesh 1 used in the special closing mesh box-shaped cavity member includes two parts: a raised V-shaped reinforcing rib 11 and a steel mesh surface 14. The special closing mesh is cold-rolled steel strip used as a processing raw material for special It is made by machine stamping and stretching; when the special closing net is pressed in the vertical direction with a combined mesh box-shaped cavity member, the bending edge 9 at the bending place needs to be quant...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com