Composite powdery blue algae treatment agent and preparation method thereof

A cyanobacteria treatment agent, powdery technology, applied in the field of high-efficiency composite powder cyanobacteria treatment agent and its preparation, can solve the problems of water pollution, non-conformity with living and drinking hygiene standards, etc., and achieve high efficiency, complete functions, and excellent coagulation performance Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0038] Mix 8 parts by weight of 80-mesh malic acid with 30 parts by weight of 80-mesh potassium sulfate for 40 minutes, then add 20 parts by weight of 80-mesh dicalcium silicate, mix for 50 minutes, then add 10 parts by weight of 80-mesh copper sulfate, and mix for 40 minutes. Then add 10 parts by weight of 80 mesh calcium carbonate and mix for 40 minutes, then add 10 parts by weight of 80 mesh potassium aluminum sulfate, mix for 40 minutes, then add 10 parts by weight of 80 mesh calcium oxide and mix for 40 minutes, then add 2 parts by weight of 80 mesh polypropylene Amide, mixed for 120 minutes, can be.

Embodiment 2

[0040]Mix 7 parts by weight of 200 mesh malic acid and 10 parts by weight of 200 mesh potassium aluminum sulfate for 50 minutes, then add 24 parts by weight of 200 mesh dicalcium silicate, mix for 90 minutes, then add 12 parts by weight of 200 mesh calcium carbonate, and mix for 50 minutes. Then add 15 parts by weight of 200 mesh copper sulfate and mix for 50 minutes, then add 15 parts by weight of 200 mesh potassium sulfate, mix for 50 minutes, then add 15 parts by weight of 200 mesh calcium oxide and mix for 50 minutes, then add 2.5 parts by weight of 200 mesh polyacrylamide , mixed for 130 minutes, you can.

Embodiment 3

[0042] Mix 10 parts by weight of 400-mesh malic acid with 5 parts by weight of 400-mesh copper sulfate for 60 minutes, then add 70 parts by weight of 400-mesh dicalcium silicate, mix for 120 minutes, then add 15 parts by weight of 400-mesh potassium sulfate, and mix for 60 minutes. Then add 20 parts by weight of 400 mesh calcium carbonate and mix for 60 minutes, then add 20 parts by weight of 400 mesh potassium aluminum sulfate, mix for 60 minutes, then add 20 parts by weight of 400 mesh calcium oxide and mix for 60 minutes, then add 3 parts by weight of 400 mesh polypropylene Amide, mixed for 150 minutes, can be.

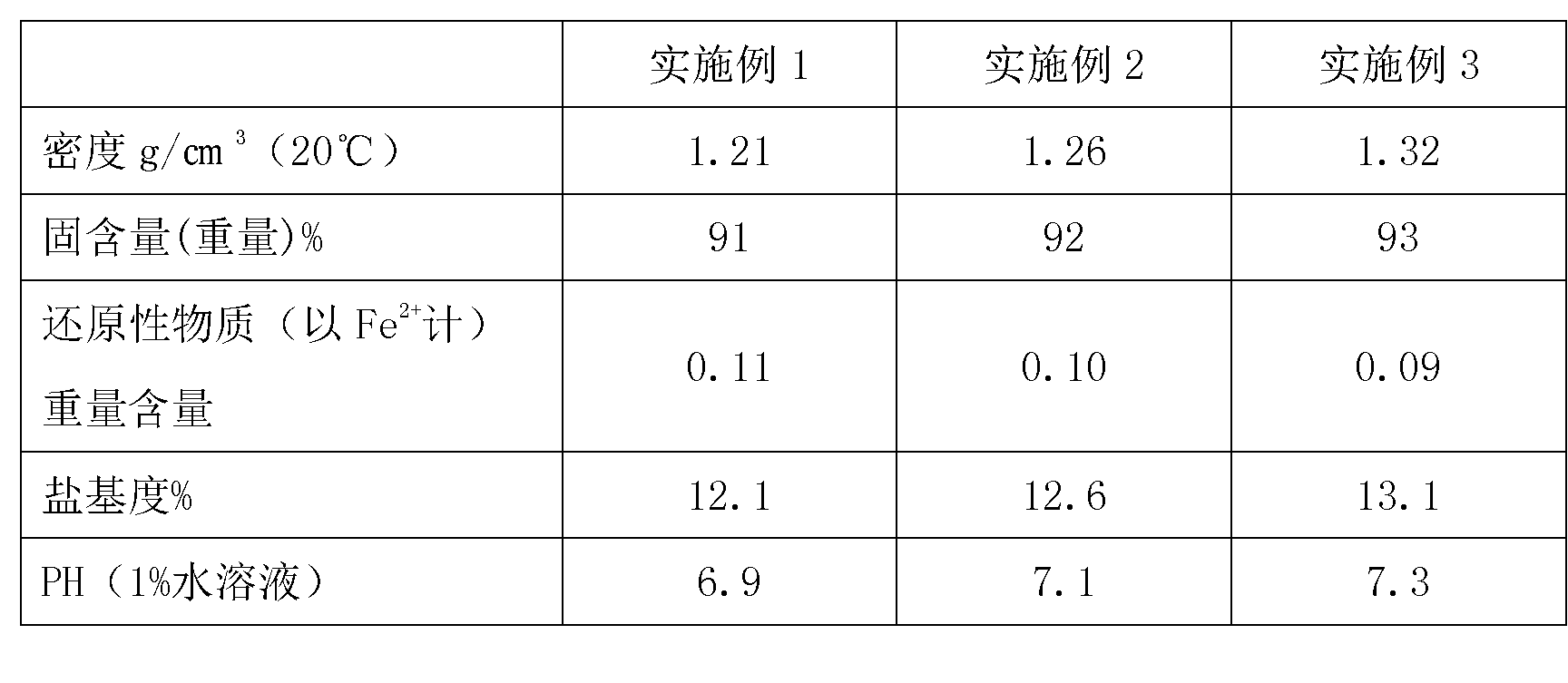

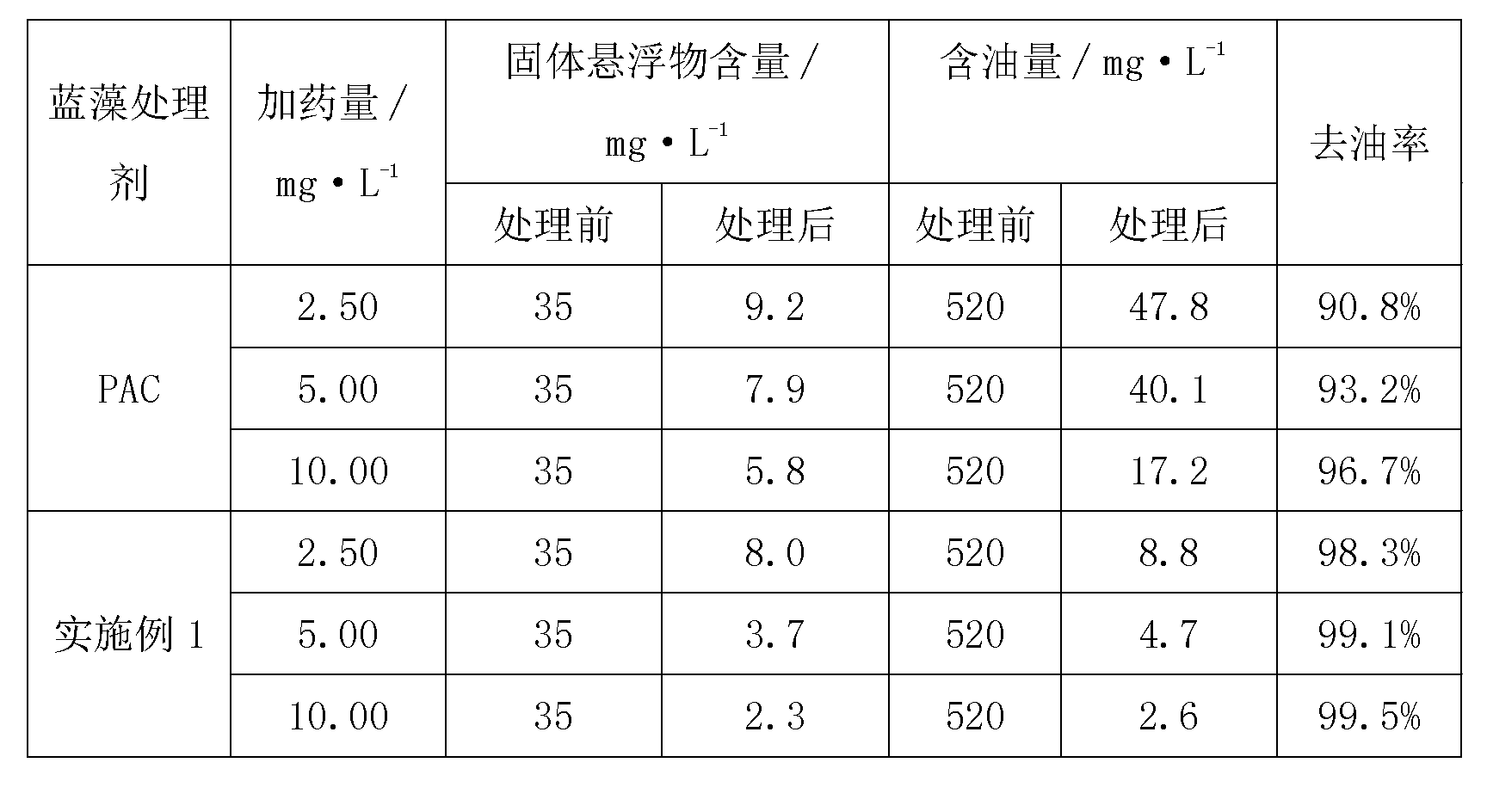

[0043] The technical index of embodiment 1-3 is as shown in table 1:

[0044] Table 1

[0045]

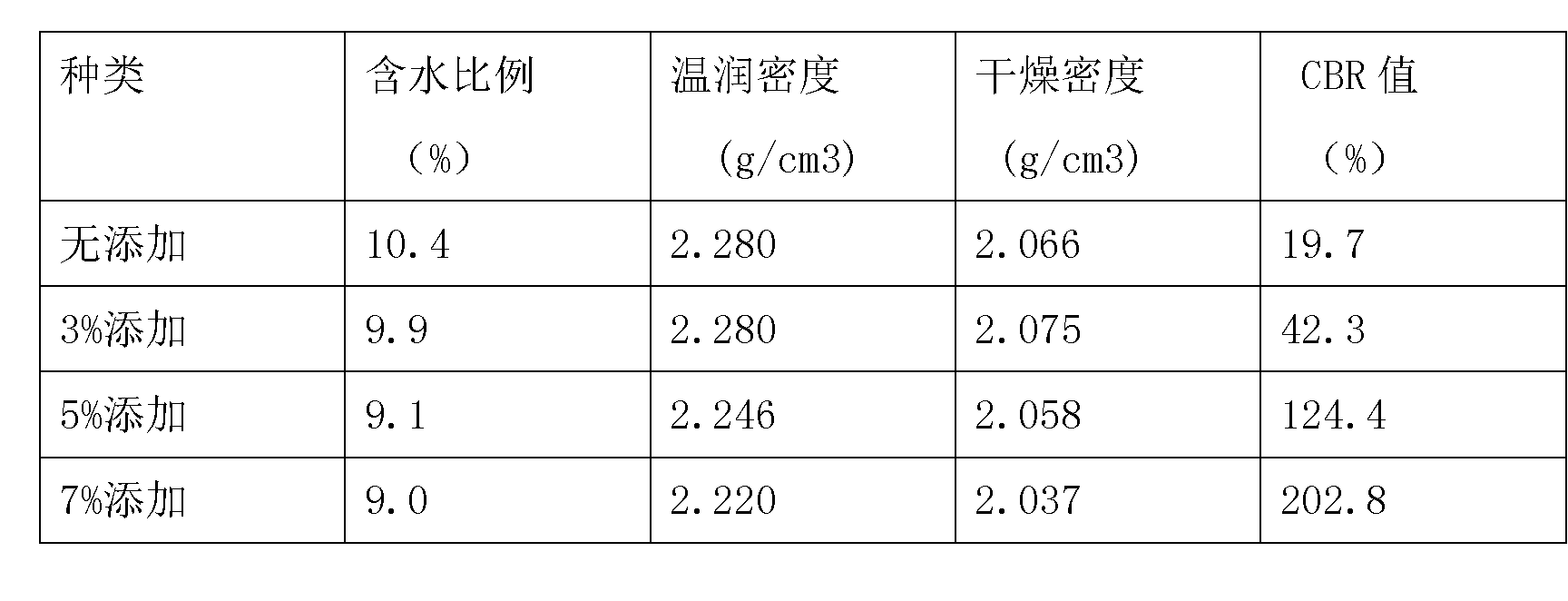

[0046] The test result of embodiment 1-3 is as shown in table 2:

[0047] Table 2

[0048]

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com