Preparation method based on photocatalytic activity for titanium dioxide nanofibers

A technology of photocatalytic activity and titanium dioxide, which is applied in the direction of titanium dioxide, chemical instruments and methods, titanium oxide/hydroxide, etc., can solve problems such as no research reports, speed up the pace of use, reduce pollution control costs, and reduce secondary pollution effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

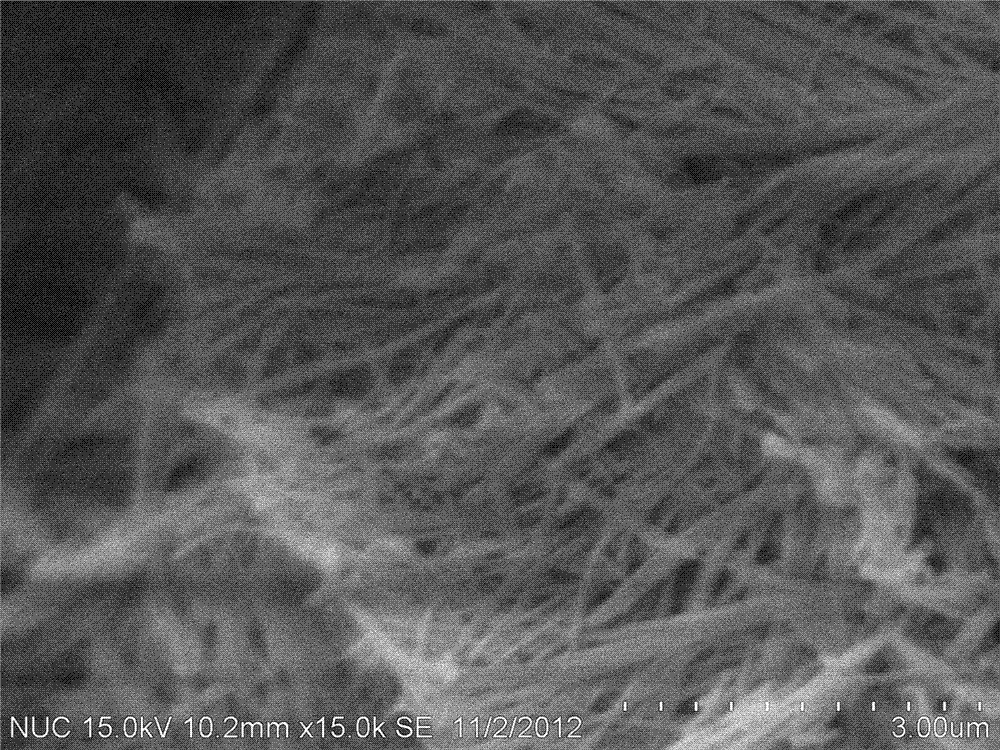

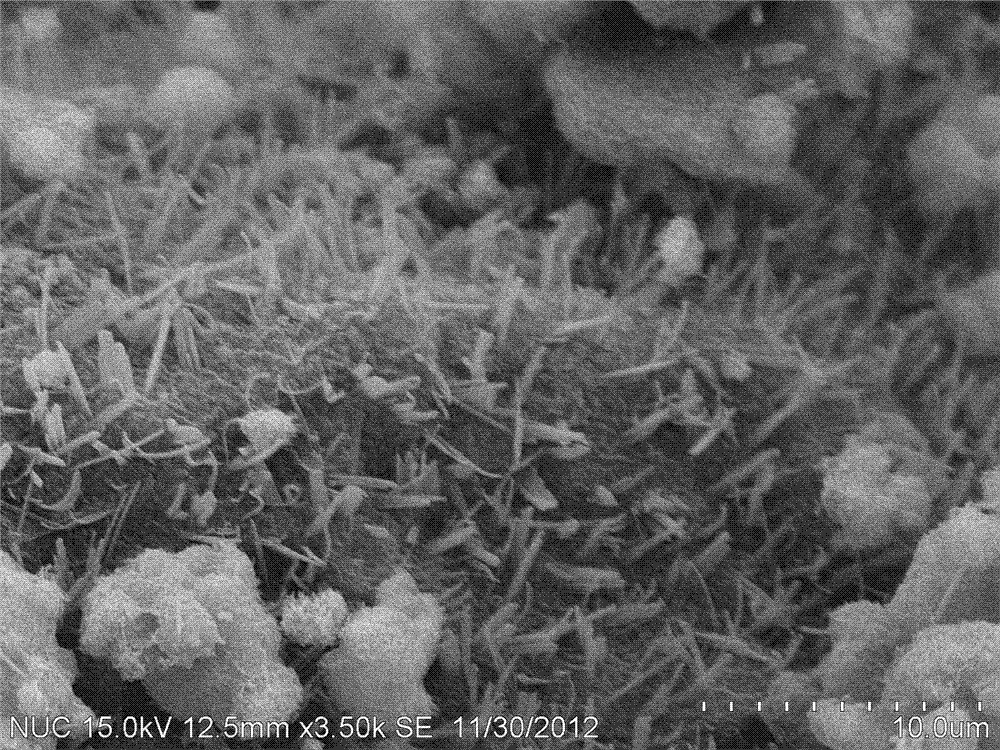

[0020] Pure anatase TiO 2 The powder is the precursor, weigh 6.7113g TiO 2 Powder, mixed with 50ml of 10mol / L NaOH aqueous solution, stirred for 30min. Take 12ml of the obtained solution and transfer it to a high-pressure reaction kettle with a capacity of 20ml, carry out hydrothermal treatment at 170°C for 72h, wash the obtained product with water until the pH is 7, filter, dry at 80°C, and calcinate at 600°C for 2h to obtain figure 1 The titanium dioxide nanofibers shown have a fiber diameter of about 30-100 nm and a length of about 3-8 μm.

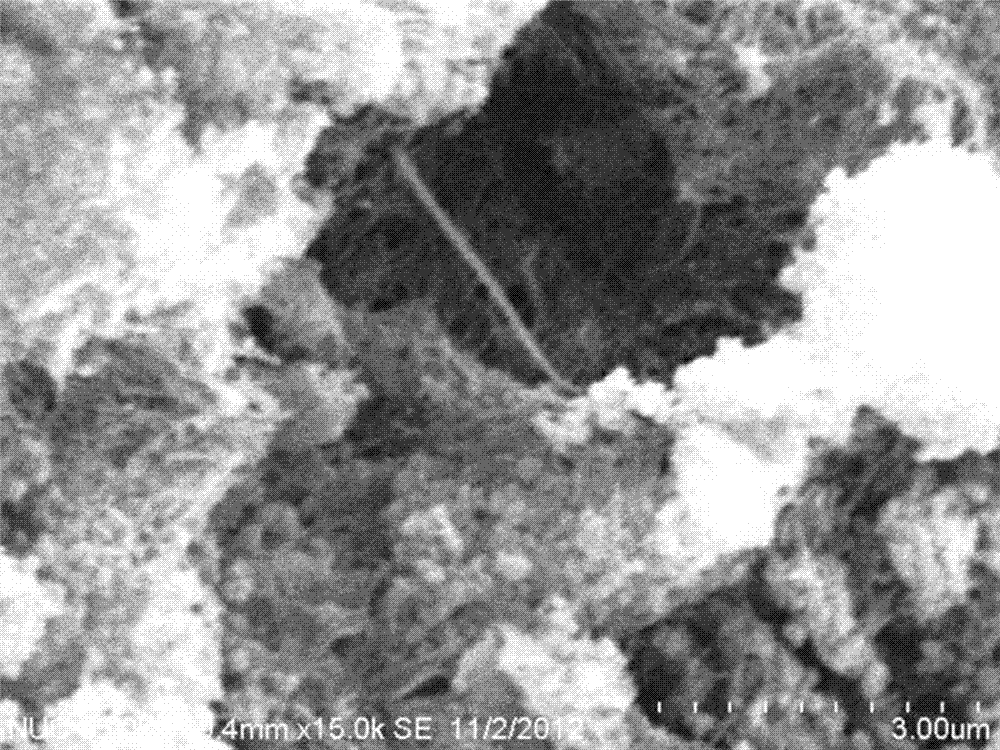

[0021] Figure 5 is the XRD pattern of the titanium dioxide nanofiber sample prepared under the above process conditions. The diffraction peak marked R in the figure is related to TiO 2 (Rutile phase) The data on the standard PDF card is in good agreement, belonging to the rutile phase TiO 2 The diffraction peaks of A, the rest of the diffraction peaks marked with A and TiO 2 (Anatase phase) The data on the standard PDF card is in...

Embodiment 2

[0023] Pure anatase TiO 2 The powder is the precursor, weigh 6.6893g TiO 2 Powder, mixed with 50ml of 12mol / L NaOH aqueous solution, stirred for 30min. Take 12ml of the obtained solution and transfer it to a high-pressure reactor with a capacity of 20ml, carry out hydrothermal treatment at 170°C for 48h, wash the obtained product with water until the pH is 7, filter, dry at 80°C, and calcinate at 600°C for 2h to obtain a product with a diameter of approximately 30-100nm, titanium dioxide nanofibers with a length of about 3-8μm.

Embodiment 3

[0025] Pure anatase TiO 2 The powder is the precursor, weigh 6.7042g TiO 2 powder, mixed with 50ml of NaOH aqueous solution with a concentration of 8mol / L, and stirred for 30min. Take 12ml of the obtained solution and transfer it to a high-pressure reactor with a capacity of 20ml, carry out hydrothermal treatment at 190°C for 24 hours, wash the obtained product with water until the pH is 7, filter, dry at 80°C, and calcinate at 600°C for 2 hours to obtain a product with a diameter of approximately 30-100nm, titanium dioxide nanofibers with a length of about 3-8μm.

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com