Device for photochemical degradating pollution gas

A photochemical and gas technology, applied in chemical instruments and methods, chemical/physical/physicochemical processes of energy application, separation of dispersed particles, etc., can solve problems such as difficult to handle adsorbates, complex equipment structure, high operating costs, etc., to achieve Avoiding economic burden, convenient manufacturing and installation, and improved purification effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

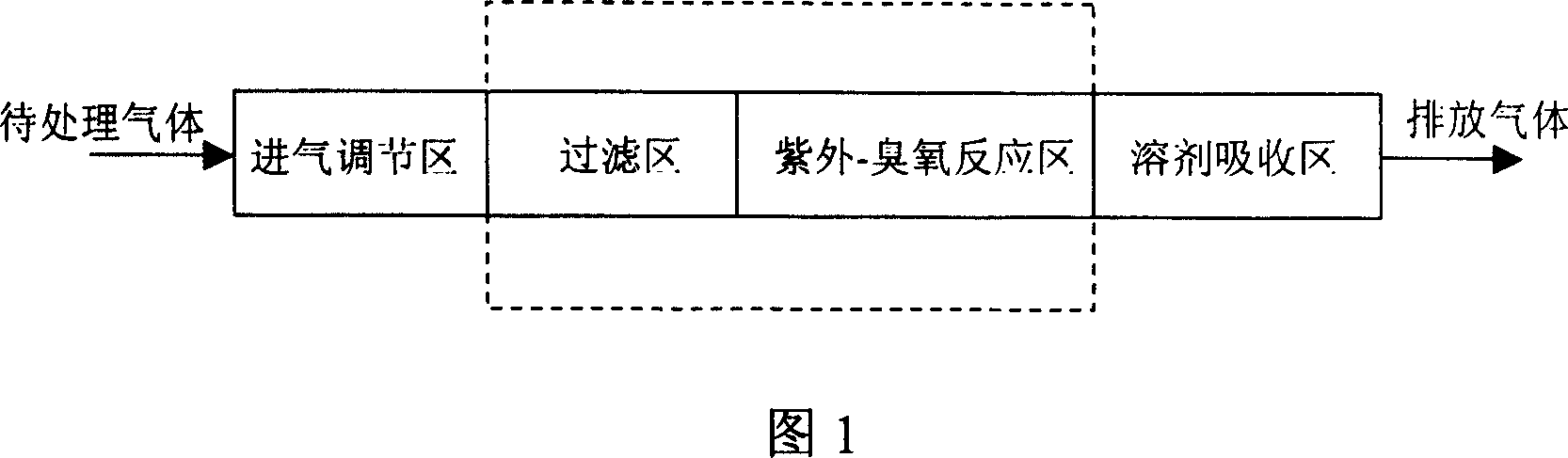

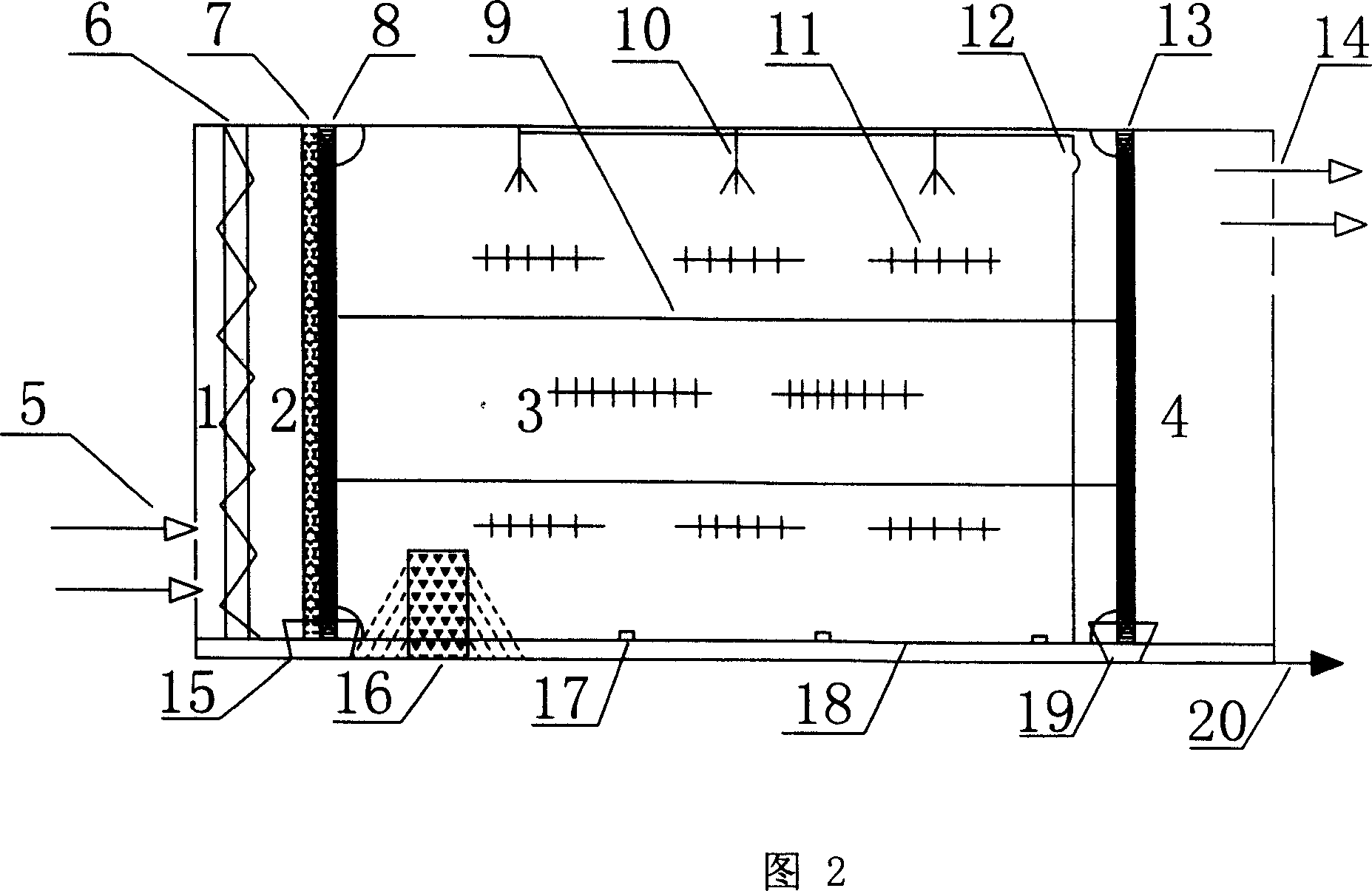

[0024] The reactor main body of the photochemical degradation polluting gas device shown in Figure 2 is a fixed building with a prism-shaped inner cavity constructed of concrete. The interior of the reactor main body is a whole, which is divided into air intake adjustment area 1 according to its function. , filter area 2, ultraviolet-ozone reaction area 3, solvent absorption area 4 four functional areas, filter area 2 and ultraviolet-ozone reaction area 3 are separated by primary filter layer 7 and secondary filter layer 8, described The ultraviolet lamp group 11 is located in the ultraviolet-ozone reaction zone 3 and is supported by a support frame 13. Each ultraviolet lamp group contains at least one ultraviolet lamp tube. When the equipment is running, there is ozone gas in the ultraviolet-ozone reaction zone 3, and the air inlet 5 and The gas outlets 14 are respectively located at the front end of the intake adjustment area 1 and the rear end of the solvent absorption area ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com