Hydrogen chloride gas circulating recovery system

A hydrogen chloride gas recycling technology, applied in the direction of chlorine/hydrogen chloride, chemical instruments and methods, dispersed particle separation, etc., can solve problems such as high treatment costs, and achieve the effect of promoting clean production, reducing pollution, and improving recovery rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

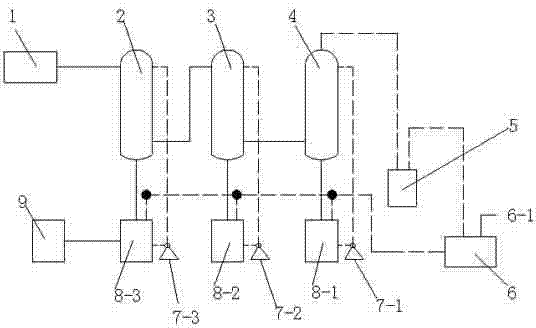

[0013] figure 1 Shown a kind of hydrogen chloride gas circulation recovery system, the main body comprises the hydrogen chloride tail gas tank 1, the first-level falling film tower 2, the second-level falling film tower 3 and the third-level packed tower 4 installed in parallel, and the gas outlet of the hydrogen chloride tail gas tank 1 and The air inlet at the upper part of the first-stage falling film tower 2 is connected; The air outlet at the lower end of the secondary falling film tower 3 is connected to the circulation tank 2 8-2, and the air outlet at the lower part of the secondary falling film tower 3 is connected to the air inlet at the lower part of the tertiary packing tower 4; the tertiary packing tower 4. The discharge port at the lower end is connected to the circulation tank 1 8-1, and the air outlet at the upper end of the three-stage packed tower 4 is connected to the air inlet of the vacuum buffer tank 5; the air outlet of the vacuum buffer tank 5 is conne...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com