Petroleum drilling waste mud reduction zero-release recycling system and method

A waste mud and oil drilling technology, applied in chemical instruments and methods, sludge treatment, water/sludge/sewage treatment, etc., can solve the problems of sustainable development of oilfields, vegetation and water pollution, transportation difficulties, etc., to achieve Reduce the cost of pollution control, reduce the cost of drilling operations, and reduce the effect of hidden dangers of pollution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

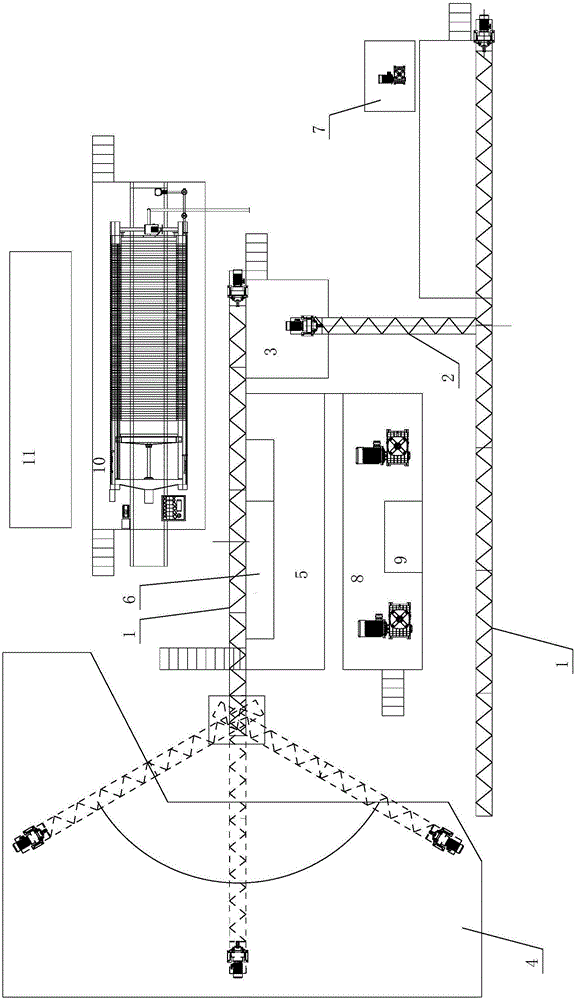

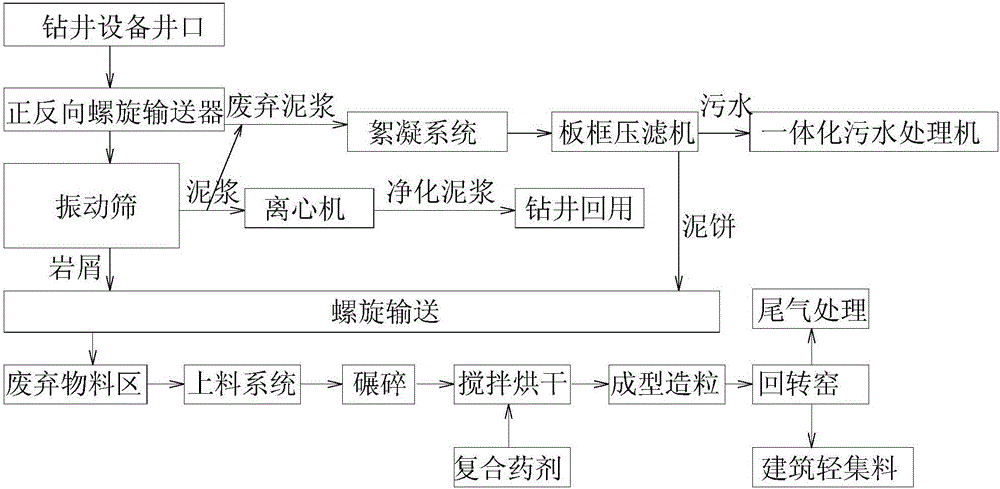

[0038] as attached figure 1 As shown, a waste oil drilling mud reduction and zero-emission reuse system includes a forward and reverse screw conveyor 1 arranged at the wellhead, and the forward and reverse screw conveyor 1 is connected to a vibrating screen 3 through a shaftless screw conveyor 2 , the vibrating screen 3 is connected to the waste material area 4 through the forward and reverse screw conveyor 1, the vibrating screen 3 is connected to the mud storage tank 5 through the pipeline, and the mud storage tank 5 is connected through the submerged slurry pump A horizontal centrifuge 6, the horizontal centrifuge 6 is connected to the waste material area 4 through the forward and reverse screw conveyor 1, and the waste material area 3 is connected by a conveyor belt to move the skid-mounted organic sewage The mud is reused in the rotary kiln.

[0039] In this embodiment, the mud storage tank 5 is connected with a mud buffer tank, the mud buffer tank is provided with a mix...

Embodiment 2

[0048] A reduction and zero-discharge reuse system for oil drilling waste mud, including a forward and reverse screw conveyor 1 arranged at the wellhead, the forward and reverse screw conveyor 1 is connected to a vibrating screen 3 through a shaftless screw conveyor 2, the The vibrating screen 3 is connected to the waste material area 4 through the forward and reverse screw conveyor 1, the vibrating screen 3 is connected to the mud storage tank 5 through the pipeline, and the mud storage tank 5 is connected to the horizontal centrifuge through the submerged slurry pump. The horizontal centrifuge 6 is connected to the waste material area 4 through the forward and reverse screw conveyor 1 .

[0049] The mud storage tank 5 is connected with a mud reaction tank 8, and the mud reaction tank 8 is connected with a dosing tank 9, and the mud reaction tank 8 is also connected with a plate and frame filter press 10 through a pipeline flocculation mechanism, and the plate and frame The f...

Embodiment 3

[0056] A method for reusing oil drilling waste mud, comprising the following steps:

[0057] A. Drilling waste mud generated during oil drilling is received by positive and negative screw conveyors, and the mud is transported to the vibrating screen by the shaftless screw conveyor; when the mud viscosity is small and thick, it cannot be transported to the vibrating screen by the shaftless screw conveyor , The mud will enter the ground tank through the pipeline at the interface between the positive and negative screw conveyor and the shaftless screw conveyor. A mixer is installed in the ground tank, and the mud is pumped into the vibrating screen by the submerged slurry pump for subsequent processing.

[0058] B. After the vibrating screen screens out the large cuttings particles, they are transported to the waste material area by the positive and negative screw conveyors. The separated mud enters the mud storage tank, and is pumped into the horizontal centrifuge by the submerge...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com