Cleaning and reduction equipment system and method for waste oil-based mud during petroleum drilling

An oil-based mud, oil drilling technology, applied in chemical instruments and methods, earthwork drilling, sludge treatment, etc., can solve the problems of complicated operation, unfavorable placement of large-sized equipment, and excessively long conveyors.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

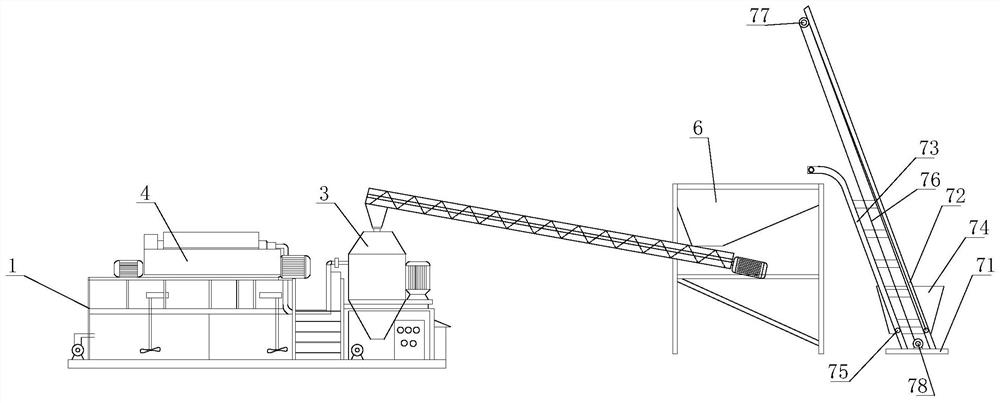

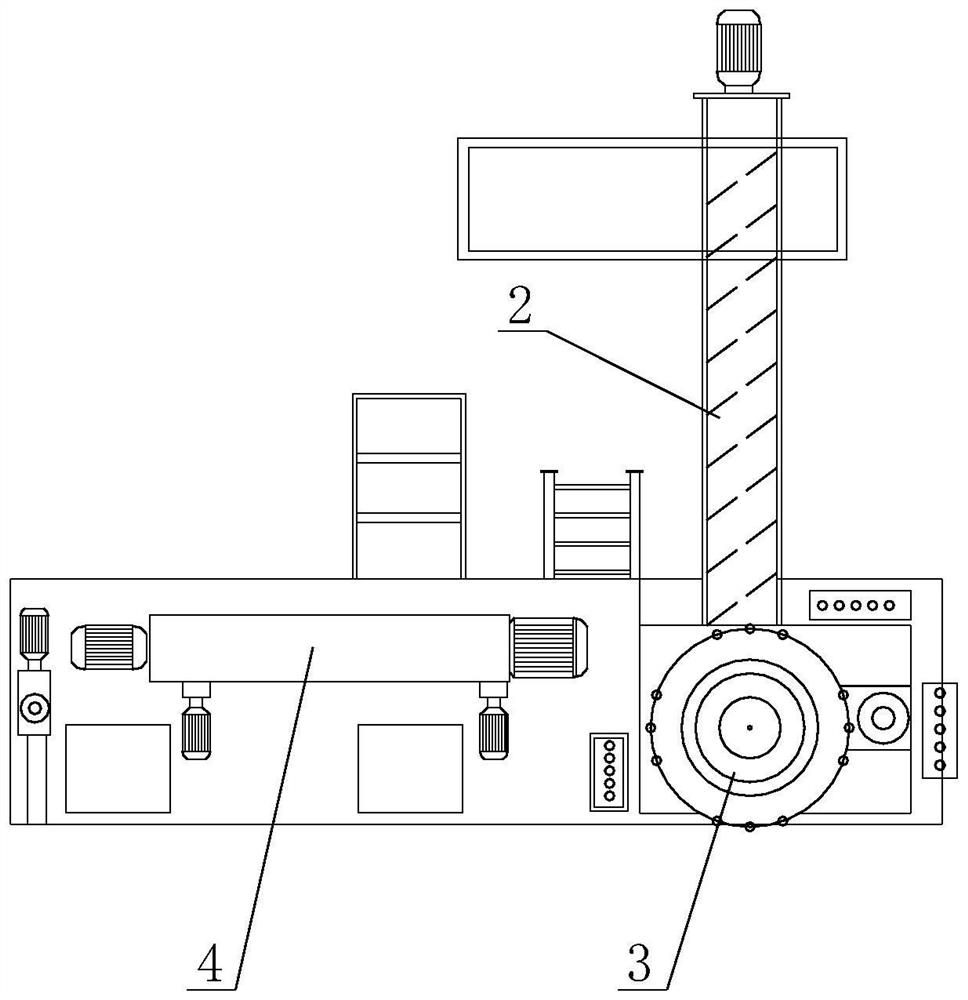

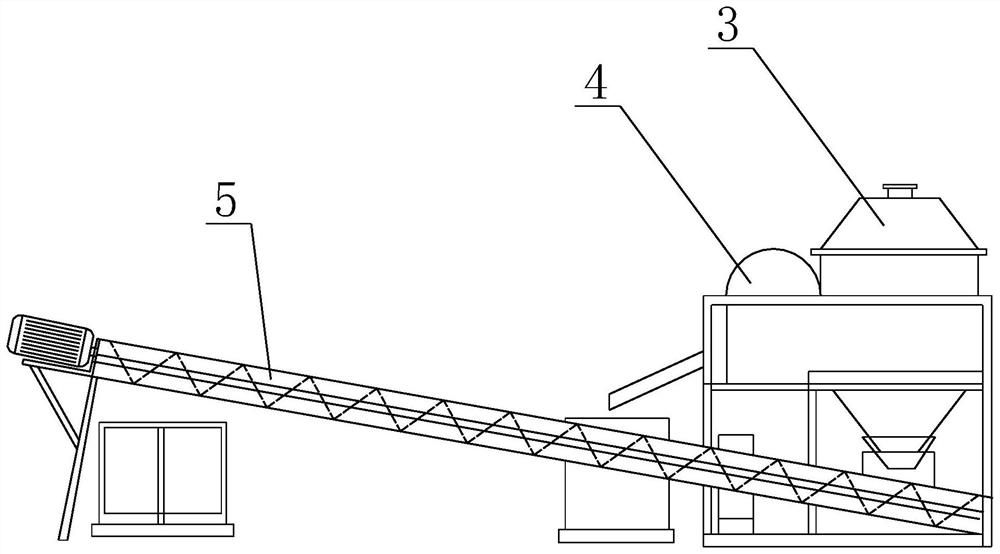

[0033] as attached Figure 1-3 As shown, an oil drilling while drilling waste oil-based mud cleaning and reduction equipment system includes a bracket 1, on which a first forward and reverse screw conveyor 2 is arranged, and one end of the first forward and reverse screw conveyor 2 is Feed, the other end is connected to the dryer 3, the dryer 3 is connected to the horizontal centrifuge 4 through the pipeline on the outer wall of the casing, and the outlet below the dryer 3 is provided with a second positive and negative screw conveyor machine 5, the mud outlet of the horizontal centrifuge 4 is connected to the second positive and negative screw conveyor 5, and the horizontal centrifuge 4 is connected to the drilling well through pipelines for transporting the treated waste oil base Mud for well drilling.

[0034] A first storage tank is arranged on the pipeline between the drying machine 3 and the horizontal centrifuge 4, and a submerged slurry pump is arranged in the first s...

Embodiment 2

[0041] This embodiment provides a method for cleaning and reducing waste oil-based mud during oil drilling. The waste drilling mud generated during oil drilling is received by the first positive and negative screw conveyor 1, and the mud can be transported to the drying machine by the shaftless screw conveyor. Dryer 3; the drying machine 3 screens out the large debris particles and transports them to the solid phase material area by the second positive and negative screw conveyor 5, and the separated mud enters the first mud storage tank and is pumped by the submerged slurry pump. into the horizontal centrifuge 4 for mud-water separation, and the horizontal centrifuge 4 separates the large coarse-grained sand and then transports it to the solid phase material area by the second positive and negative screw conveyor 5; the separated mud is returned to the solid phase material area through the mud pump. used in drilling.

[0042] When the amount of mud is large, part of the mud e...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com