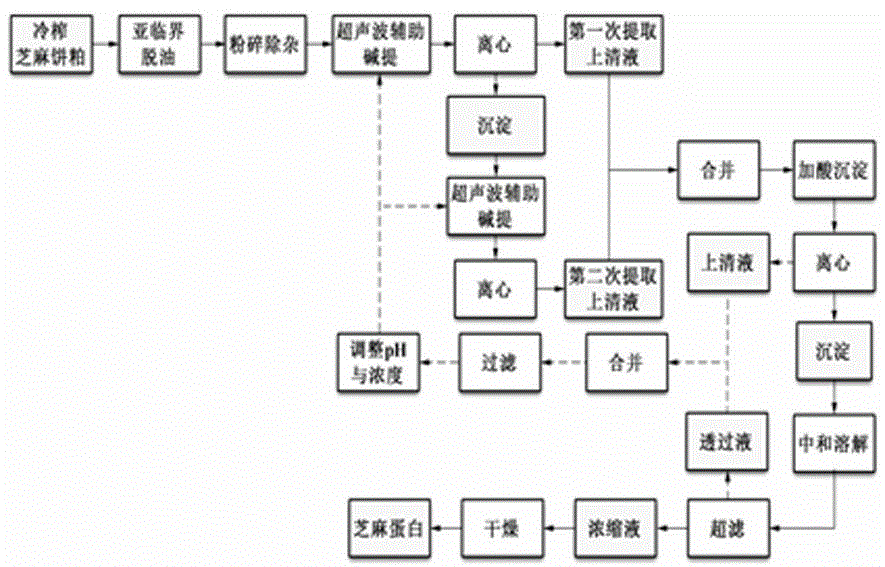

Method for ultrasonic-assisted weak base extraction of proteins in cold-pressed sesame cake meal

A technology for extracting sesame cakes and weak bases, which is applied in plant protein processing and tissue treatment, can solve the problems of reducing the quality of sesame protein, increasing investment in equipment and pollution control, and reducing the cost of equipment corrosion and pollution control. The effect of shortening production time and improving product quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

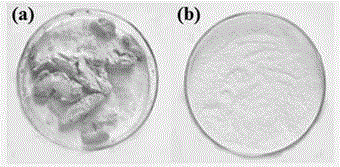

Image

Examples

Embodiment 1

[0032] A method for ultrasonically assisted weak base extraction of protein in cold-pressed sesame cakes, comprising the steps of:

[0033] 1) Subcritical deoiling pretreatment of cold-pressed sesame cake:

[0034] Take 10kg of cold-pressed sesame cake, crush it to 40 mesh, put it into a nylon bag, put it into a subcritical extraction tank, add liquefied butane as a subcritical fluid for extraction according to the ratio of solid to liquid 1kg:4L, and extract to the cake The residual oil in the meal is less than 1% (extracted 3 times at 40°C, 30min each time). Then distill under reduced pressure at -0.10MPa and 50°C for 60 minutes to remove residual liquefied butane, and remove the sesame cake of liquefied butane for later use;

[0035] 2) Sesame protein extraction:

[0036] a: Take 1kg of the sesame cake obtained in step 1) and crush it to 80 mesh, then add 9L of 0.3mol / L sodium chloride aqueous solution, and adjust the pH to 9.5 with 1mol / L sodium hydroxide, and then trans...

Embodiment 2

[0044] A method for ultrasonically assisted weak base extraction of protein in cold-pressed sesame cakes, comprising the steps of:

[0045] 1) Subcritical deoiling pretreatment of cold-pressed sesame cake:

[0046] Take 15kg of cold-pressed sesame cake, crush it to 40 mesh, put it into a nylon bag, put it into a subcritical extraction tank, add liquefied propane as a subcritical fluid for extraction according to the ratio of solid to liquid 1kg:3L, and extract to the cake The residual oil is less than 1% (extracted 5 times at 40°C, each extraction 30min). Then distill under reduced pressure at -0.10MPa and 60°C for 80 minutes to remove residual liquefied propane, and remove the sesame cake of liquefied propane for later use;

[0047] 2) Sesame protein extraction:

[0048] a: Take 1kg of the sesame cake obtained in step 1) and crush it to 120 mesh, then add 9L of 0.6mol / L sodium chloride aqueous solution, and adjust the pH to 10.0 with 1mol / L sodium hydroxide, and then transf...

Embodiment 3

[0054] A method for ultrasonically assisted weak base extraction of protein in cold-pressed sesame cakes, comprising the steps of:

[0055] 1) Subcritical deoiling pretreatment of cold-pressed sesame cake:

[0056] Take 10kg of cold-pressed sesame cake, crush it to 20 mesh, put it into a cloth bag, put it into a subcritical extraction tank, add liquefied butane as a subcritical fluid for extraction according to the ratio of material to liquid: 1kg:4L, and extract to the cake The residual oil is less than 1% (extracted 5 times at 40°C, each extraction 30min). Then distill under reduced pressure at -0.10MPa and 65°C for 90 minutes to remove residual liquefied butane, and remove the sesame cake of liquefied butane for later use;

[0057] 2) Sesame protein extraction:

[0058] a: Take 0.5kg of the sesame cake obtained in step 1) and grind it to 160 mesh, then add 9.5L of 0.5mol / L sodium chloride aqueous solution, and adjust the pH to 9.0 with 1mol / L sodium hydroxide, and then tr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com