Process for weaving upper weft float hollow jacquard terry on warp-knitting circular weaving machine

A terry, double-sided technology, applied in the field of knitted jacquard terry, to achieve the effect of increasing product varieties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

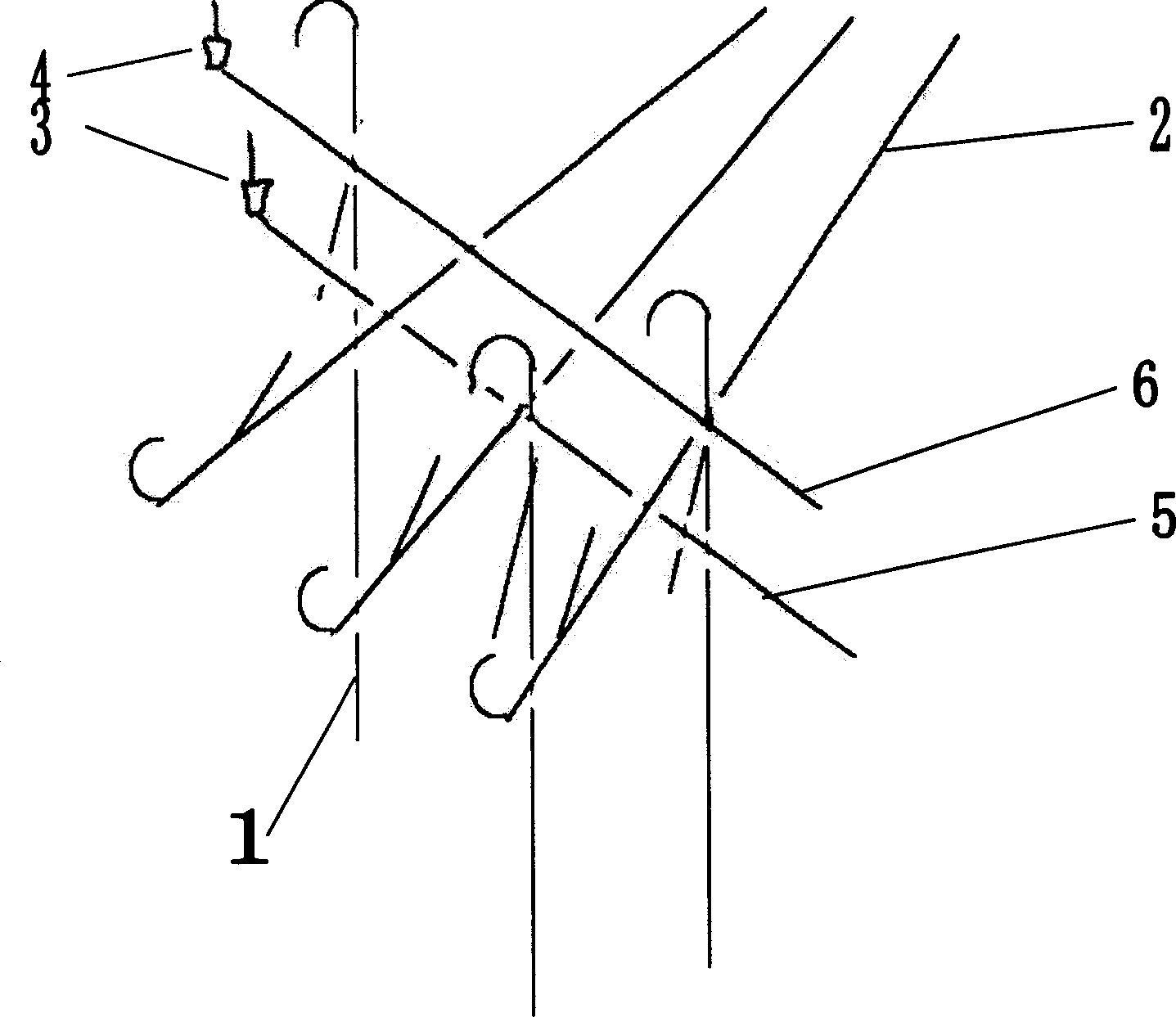

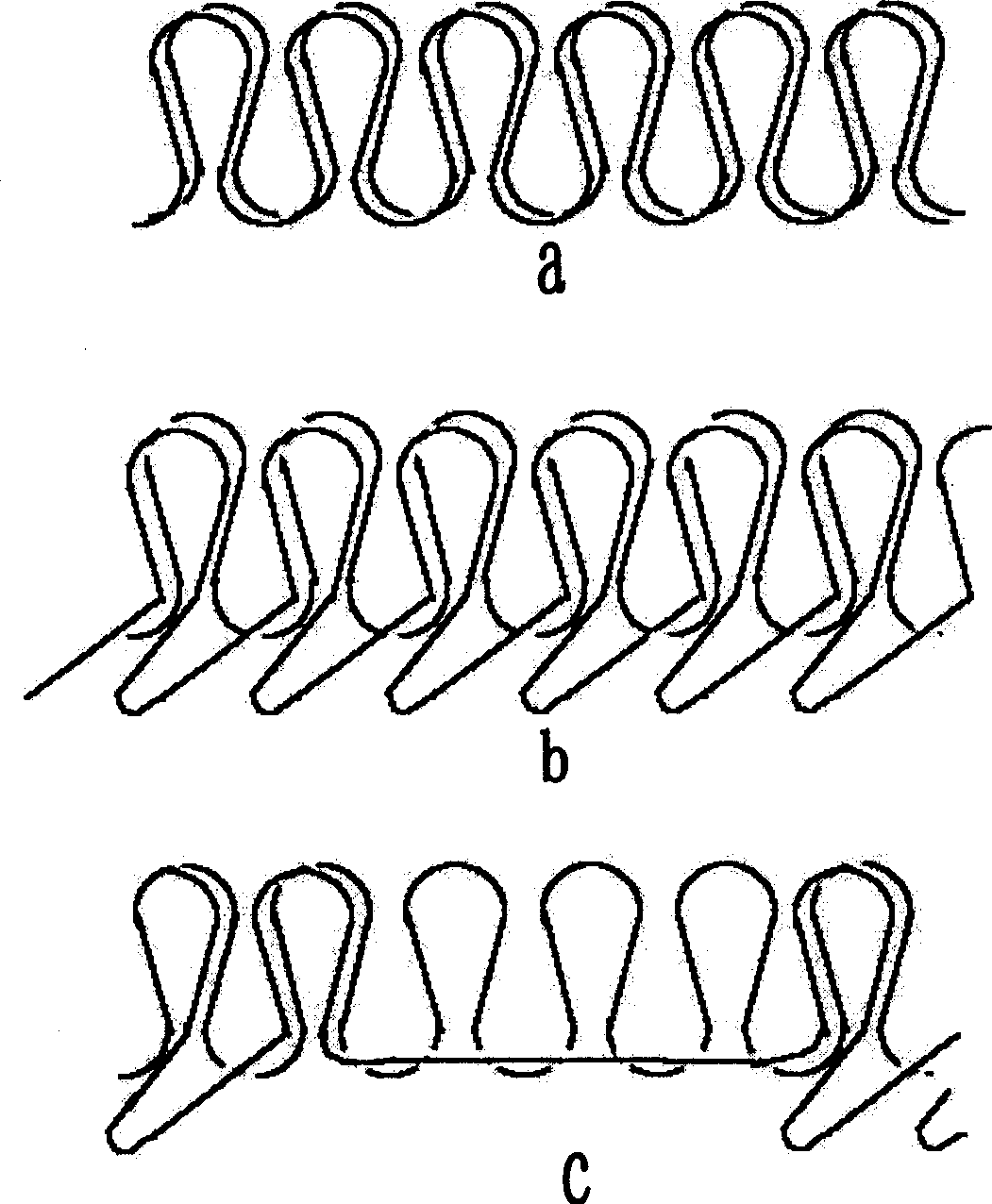

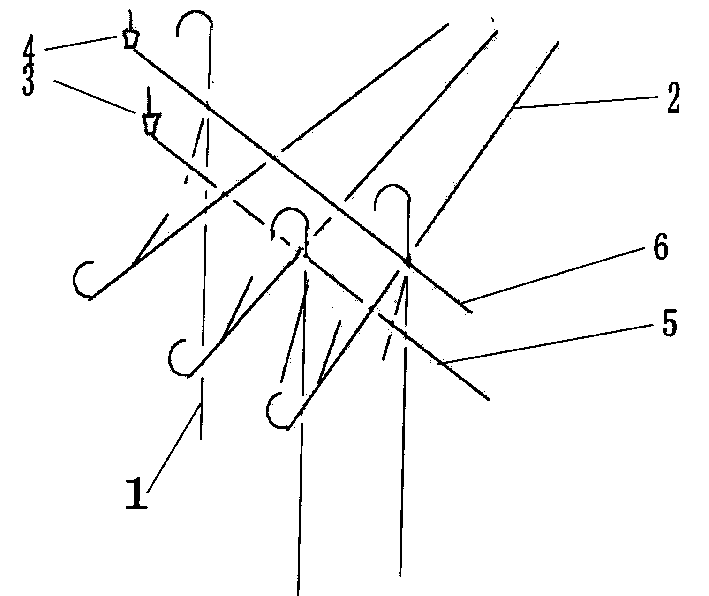

[0009] The specific implementation and steps of the present invention weaving floating line hollow jacquard terry are as follows: cylinder needle 1 and dial needle 2 are used on the weft knitting machine ( figure 1 ), during the knitting process of each way, the cylinder needle 1 selectively forms two high and low heights after the loop is withdrawn, and there are two low and high yarn guide positions 3 and 4, and the ground yarn 5 position 3 is lower, Under the dial needle 2, it is placed in the needle opening of all cylinder needles 1, and the loop yarn 6 is placed higher at position 4, and the loop yarn 6 is placed on the dial needle 2 and before the high cylinder needle . In the knitting process of the bent yarn after laying, the ground yarn and the pile yarn on the needle pad of the high-position needle cylinder form a loop structure under the distinction that the dial holds the pile yarn and does not work on the ground yarn, such as figure 2 The loop structure shown in...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com