Rectifying tower forrecovering oxygen-bearing organic matter inwater for Fischer-Tropsch synthesis

A Fischer-Tropsch synthesis and rectification tower technology, which is applied in the field of rectification towers, can solve the problems of high cost, low content, and it is difficult to meet environmental protection requirements, and achieves the effect of solving the problem of environmental pollution and increasing product varieties.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] The present invention will be further described below in conjunction with embodiment.

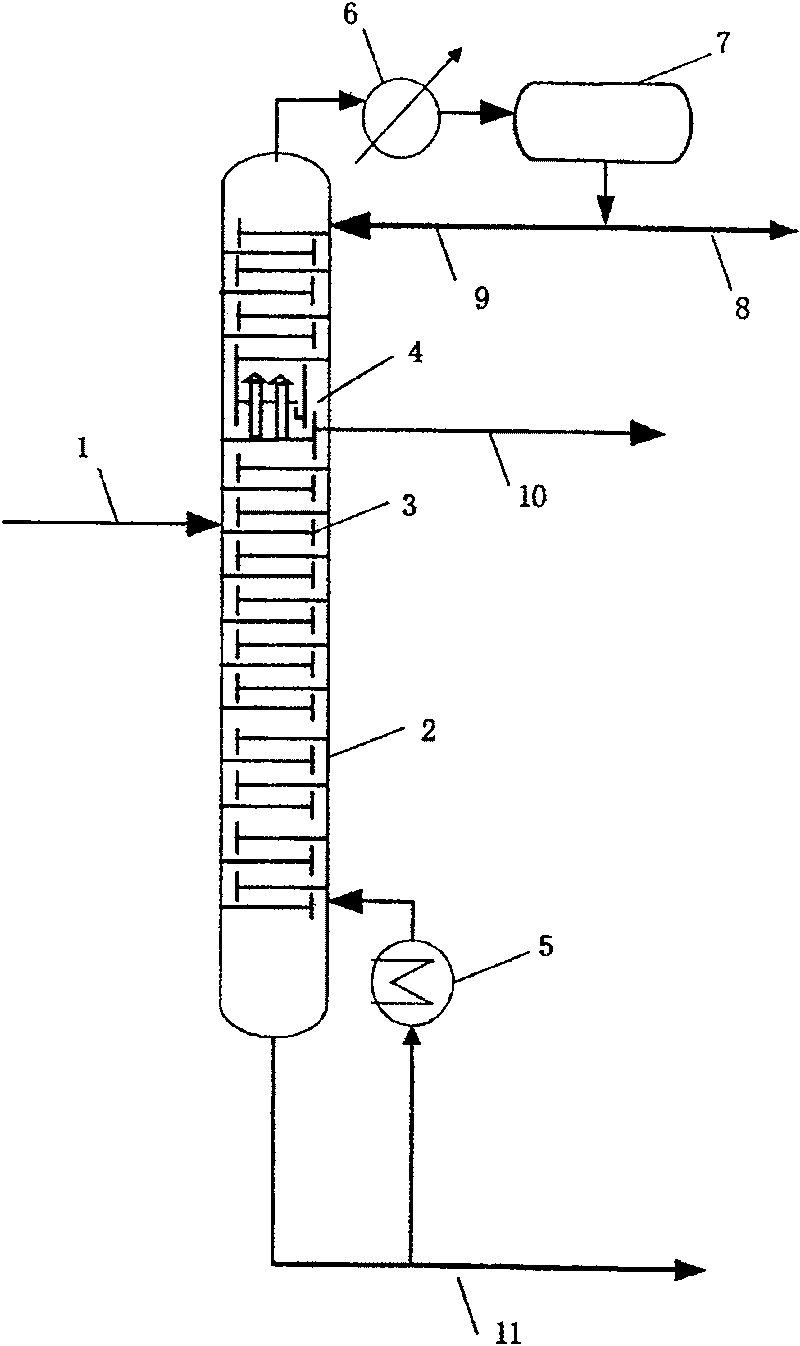

[0025] like figure 1 As shown, the main body of a rectification column for recovery of oxygenated organics in Fischer-Tropsch synthesis reaction water consists of a column body 2, 28 trays, a bottom reboiler 5, a top condenser 6 and related pipelines. Among them, 1 is the feed pipeline, 10 is the side line extraction pipeline, 11 is the discharge pipeline of acidic wastewater from the tower kettle, 8 is the extraction pipeline of the tower top product, and 9 is the circulation loop. 7 is a condensate return tank, 4 is a chimney plate, and 3 is a feed plate.

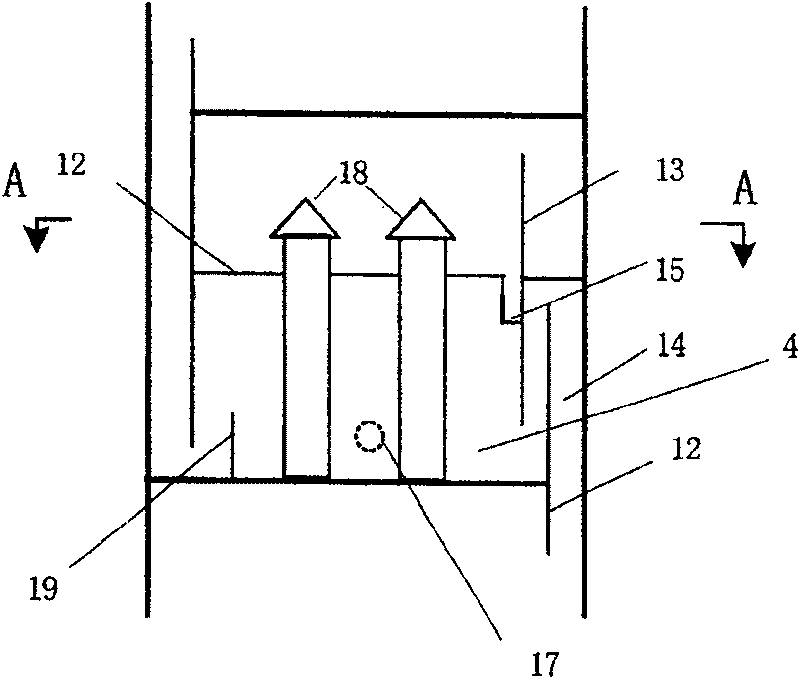

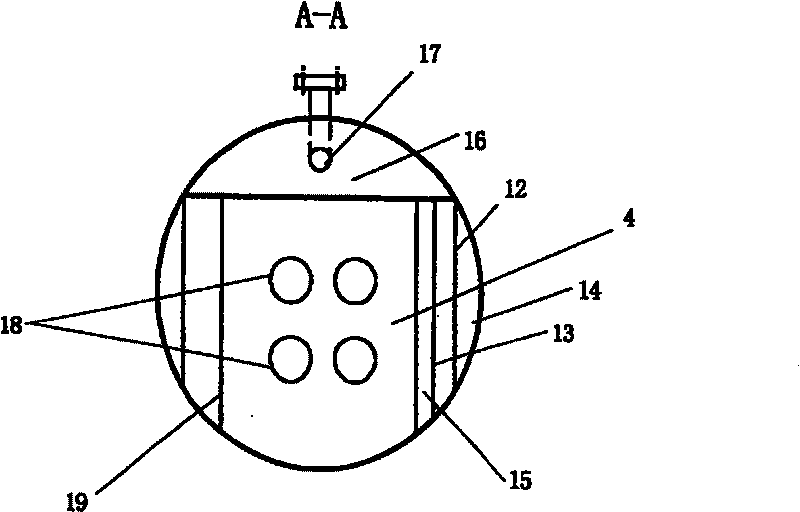

[0026] figure 2 , image 3 Shown are respectively the structural schematic diagrams of the chimney plate 4 in two viewing directions, figure 2 for the side view, image 3 It is a top view. 12 is the downcomer plate. The height of the downcomer plate 12 is designed according to the liquid phase residence time on the tray f...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com