Cereal beverage and preparation method thereof

A technology for beverages and cereals, applied in the field of cereal beverages and their preparation, can solve the problems of affecting the flavor of products, unable to completely retain the nutritional components of cereal raw materials, unable to decompose proteins, etc., so as to improve the utilization rate of raw materials and solve the dipeptide taste. Bitter, good for digestion and absorption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

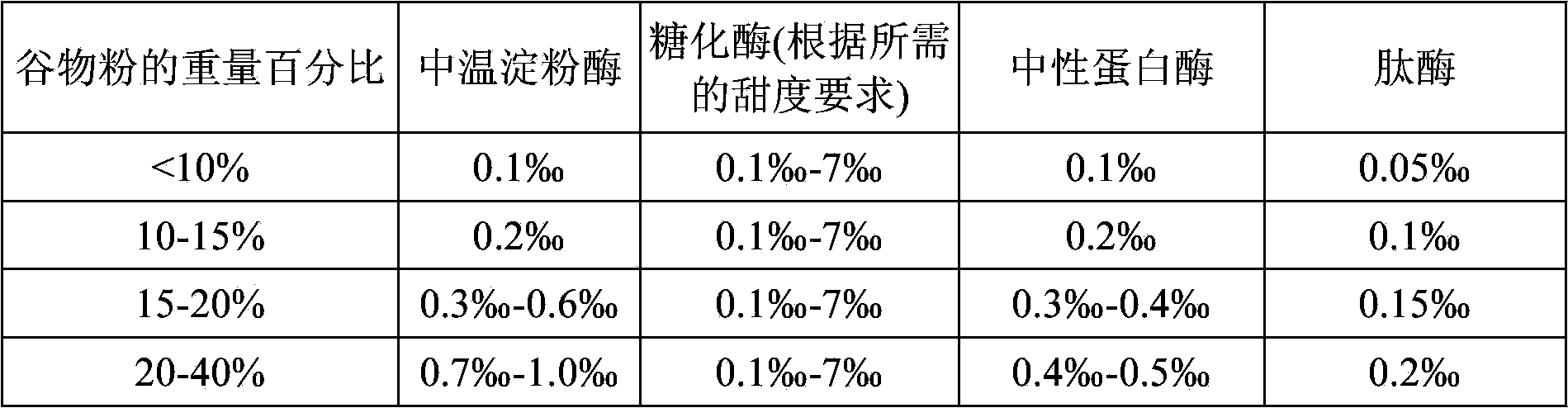

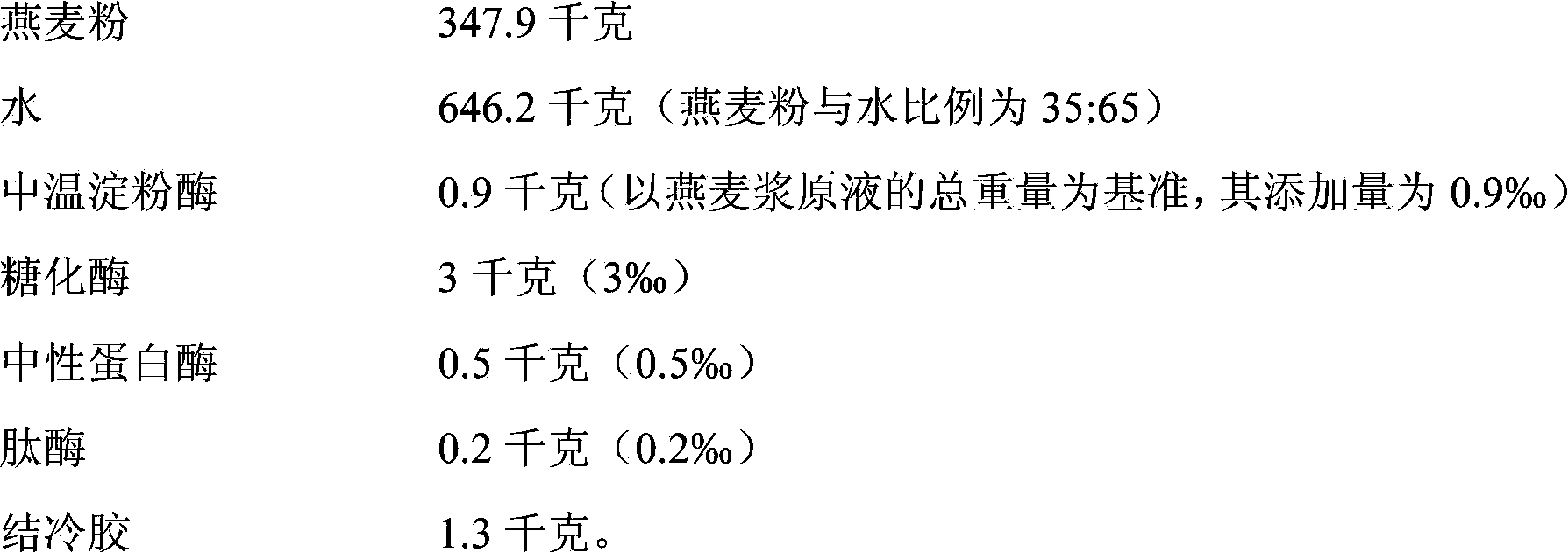

[0041] This embodiment provides an oatmeal drink and a preparation method thereof. Wherein, the formula of the oatmeal drink is (in terms of one ton of product):

[0042]

[0043] The preparation method of the oatmeal drink of the present embodiment comprises the following steps:

[0044] Ingredients: Add oat flour to water at 80±2°C, stir for 10 minutes until the two are evenly mixed to obtain oat pulp stock solution;

[0045] Enzymolysis: under the conditions of 60°C-65°C, 80-800 rev / min stirring, add medium-temperature amylase, glucoamylase, neutral protease and peptidase into oat pulp stock solution for enzymolysis reaction. Detect the viscosity of the above-mentioned grain pulp subjected to the enzymolysis reaction in 10 minutes, and stop the reaction until the viscosity of the grain pulp subjected to the enzymolysis reaction is constant to obtain an enzymolysis grain pulp;

[0046] Constant volume: heat up the above-mentioned enzymatically hydrolyzed grain pulp to 7...

Embodiment 2

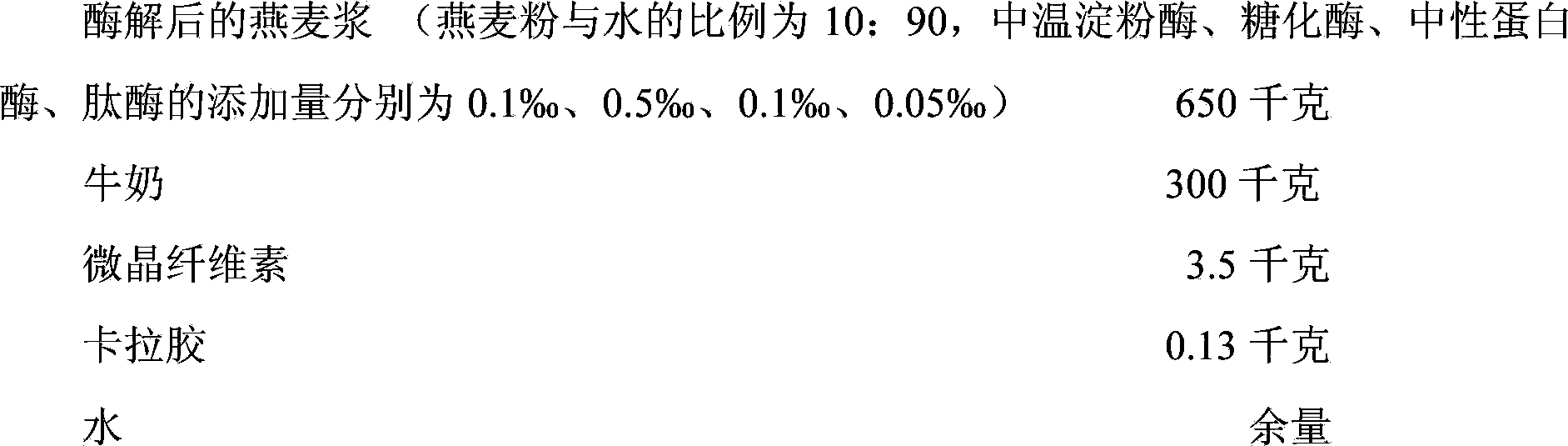

[0052] This embodiment provides an oat milk drink and a preparation method thereof. Wherein, the formula of the oat milk drink is (based on one ton of product):

[0053]

[0054] The preparation method of the oat milk beverage of the present embodiment comprises the following steps:

[0055] Batching and enzymolysis steps are identical with the corresponding steps of embodiment 1;

[0056] Constant volume: Add milk to the enzymatically hydrolyzed oat pulp, heat up to 75±5°C, add microcrystalline cellulose and carrageenan, and stabilize the volume after 15 minutes;

[0057] Homogenization: Homogenize the enzymatically hydrolyzed oat pulp at 15-25MPa, 50-70°C;

[0058] Enzyme elimination and sterilization: the homogenized grain pulp is subjected to enzyme elimination and sterilization at 137°C / 4 seconds to achieve commercial sterility;

[0059] Filling: filling the sterilized cereal slurry to obtain an oat milk drink.

[0060] The product characteristics of the oat milk d...

Embodiment 3

[0062] This embodiment provides a red grain drink and a preparation method thereof. Wherein, the formula of this red valley drink is (in terms of one ton of product):

[0063]

[0064] The preparation method of the red valley drink of the present embodiment may further comprise the steps:

[0065] The batching and enzymolysis steps of red soybean milk after enzymolysis and red rice milk after enzymolysis are all the same as the corresponding steps of embodiment 1;

[0066] Constant volume: mix the enzymatically hydrolyzed red soybean milk and enzymolyzed red rice milk, add peanut butter, heat up to 75±5°C, add gellan gum, carrageenan and sucrose fatty acid ester, and stabilize the volume after 15 minutes;

[0067] Homogenization: Homogenize the enzymatically hydrolyzed grain pulp after constant volume at 15-25MPa, 50-70°C;

[0068] Enzyme elimination and sterilization: the homogenized grain pulp is subjected to enzyme elimination and sterilization at 137°C / 4 seconds to ac...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Viscosity | aaaaa | aaaaa |

| Viscosity | aaaaa | aaaaa |

| Viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com