Liquid nitrogen washing device with function of producing natural gas

A natural gas and liquid nitrogen washing technology, applied in the field of coal chemical industry, can solve the problems such as the liquid nitrogen washing device cannot operate normally, and achieve the effect of ensuring long-term stable operation and increasing business opportunities.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

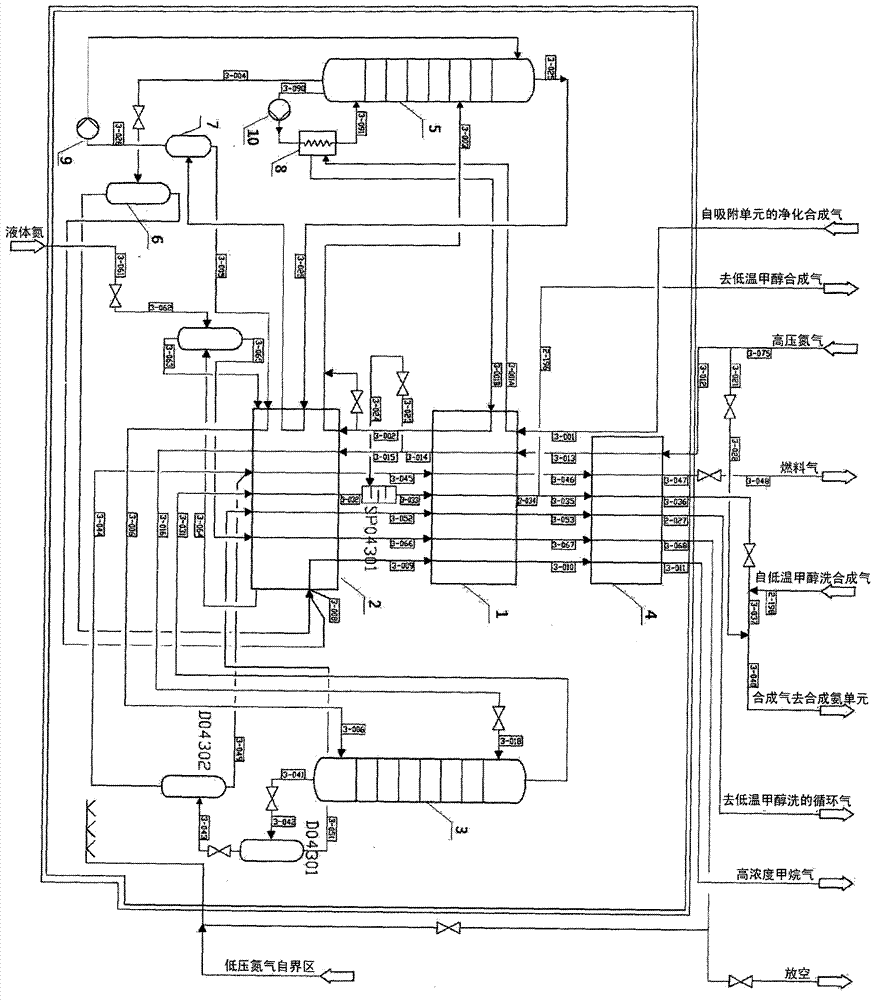

[0027] The purified syngas first enters the molecular sieve adsorber in the liquid nitrogen washing device, and the trace amount of CO contained in it 2 and CH 3 OH is adsorbed in the adsorber. Afterwards, the purified synthesis gas (3-001 stream) enters the first raw gas cooler in the "cold box", and is cooled to about -128°C by several reheated streams; then enters the second raw gas cooler and continues It is cooled to about -155°C by several reheated streams and drawn from the middle of the second raw material gas cooler, and sent to the middle of the demethanizer into the tower. At this time, the stream entering the tower is close to the bubble point state and contains a small amount of liquid phase: the gas phase flows to the top of the tower, and the liquid phase flows to the bottom of the tower.

[0028] The bottom fraction (i.e. natural gas) enters the bottom fraction separator after decompression, and the separated gas / liquid two-phase, that is, the cooler, reheats...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com