Steel material texture detection method and device utilizing same

A detection method and material technology, applied in the direction of metal processing equipment, metal processing, manufacturing tools, etc., can solve the problems that cannot be popularized and applied, difficult to distinguish, etc., and achieve the effect of avoiding production safety hazards and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0023] As shown in the accompanying drawings, a steel material detection method for a numerically controlled angle steel typing punching and shearing production line / numerically controlled plate punching typewriter, which includes the following steps:

[0024] (1) Set up a pressure detection device on the CNC angle steel typing punching and shearing production line / NC plate punching typewriter to collect pressure values when the workpiece to be detected is punched. The pressure detection device communicates with the CNC angle steel typing punch through the CNC communication system The microcomputer of the hole cutting production line / numerical control plate punching typewriter is connected and the collected pressure data is transmitted to the microcomputer; the microcomputer is connected with an alarm device. In the present invention, the pressure detection device can adopt a pressure sensor, which can be set in the hydraulic system of the numerical control angle steel typi...

Embodiment 2

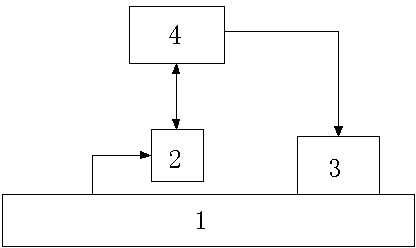

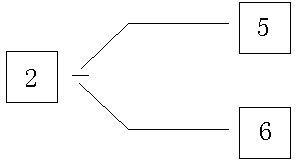

[0029] As shown in the accompanying drawings, a CNC angle steel / plate punching and typing equipment includes a host, a hydraulic system matched with the host, a microcomputer 4 for controlling the operation of the equipment, a pressure detection device 2, and an alarm device 3 . A pressure detection device 2 is set in the hydraulic system, and the pressure detection device 2 includes a pressure sensor 5 for collecting the high-pressure value of the hydraulic system when the workpiece to be detected is punched. Said microcomputer 4 is connected. The microcomputer 4 has a built-in standard punching pressure database of angle steels / plates of various materials, and the microcomputer 4 is connected with an alarm device 3 . Described alarm device 3 can adopt sound and light alarm device or adopt the alarm device built in microcomputer.

[0030]The working process of the present invention is: when the workpiece to be measured is punched, the pressure sensor 5 of the pressure detect...

Embodiment 3

[0033] This embodiment is basically the same as Embodiment 2, the difference is that the pressure detection device 2 in this embodiment uses a strain gauge pressure sensor, which is arranged on the force-bearing unit of the punching unit of the CNC angle steel / plate punching equipment Structurally, it is used to collect the pressure value of the load-bearing structure when the workpiece to be detected is punched. The load-bearing structure may be the body of the punching unit or the punch or the punch rod or the pressure head of the punching cylinder or the piston rod of the punching cylinder.

[0034] Other parts of this embodiment are the same as those of Embodiment 2, and will not be repeated here.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com