Corona device of plane lid printing machine

A corona and flat technology, applied in the general parts of printing machinery, printing machines, printing and other directions, can solve the problems of short circuit and inability to be widely used, and achieve the effect of good effect, extensive use value and uniform prepress treatment.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

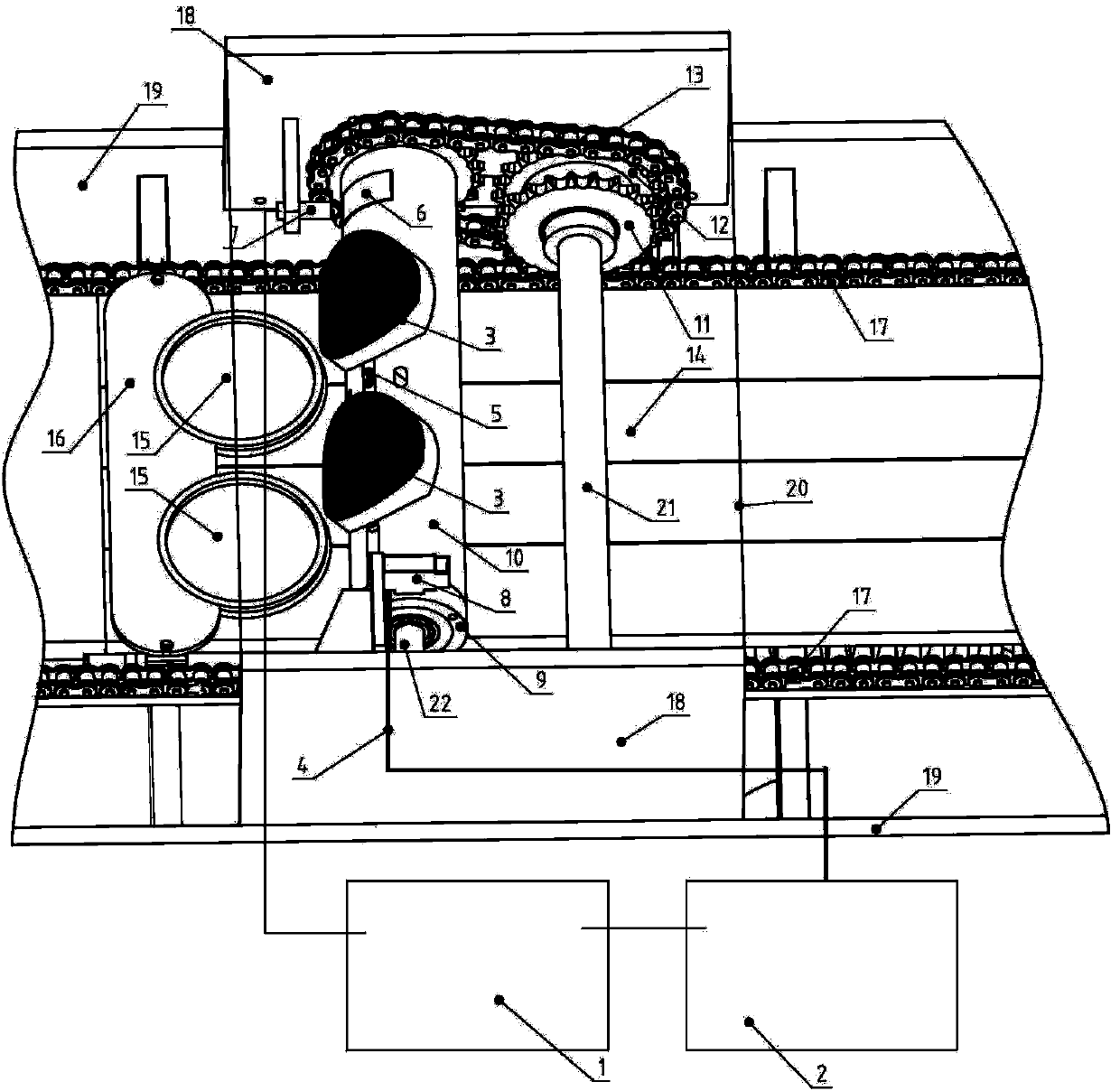

[0018] In order to further explain the technical means and effects adopted by the present invention to achieve the intended purpose of the invention, the specific implementation of the corona device of a flat stamping machine proposed according to the present invention will be described below in conjunction with the accompanying drawings and preferred examples , structure and control mode features and their functions are detailed as follows:

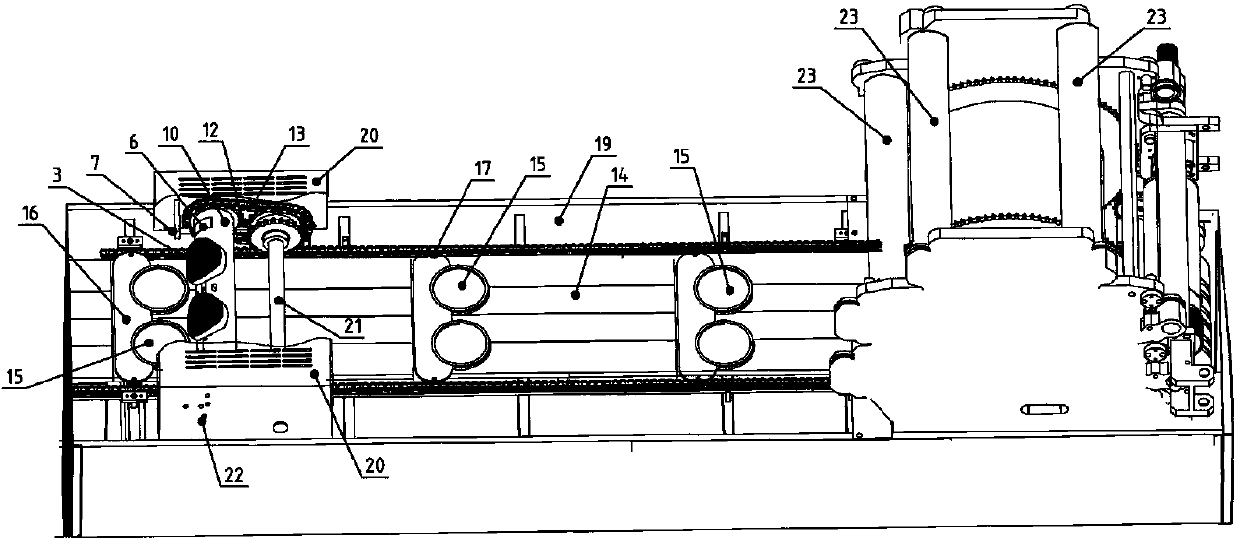

[0019] Such as Figure 1-2 As shown, the corona device of a flat stamping machine is mainly composed of: controller (1) (programmable controller or embedded controller can also be used, hereinafter referred to as controller), corona device (2), arc Discharge electrode (3), high voltage wire (4), conductive connecting plate (5), power transmission sensor (6), power transmission sensor (7), carbon brush (8), wiring copper wheel (9), insulating roller (10 ), driving sprocket (11), synchronous sprocket (12), synchronous chain (13), conveyin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com