Curing kiln for prefabricated interlock pieces and curing process for curing kiln

A technology for interlocking sheets and curing kilns, which is applied to manufacturing tools, ceramic molding machines, etc., can solve the problems of reducing the quality and yield of finished products, being easily affected by human factors, and being easily affected by the weather and environment, so as to improve work efficiency. efficiency, improving construction quality and production efficiency, and shortening the construction period

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

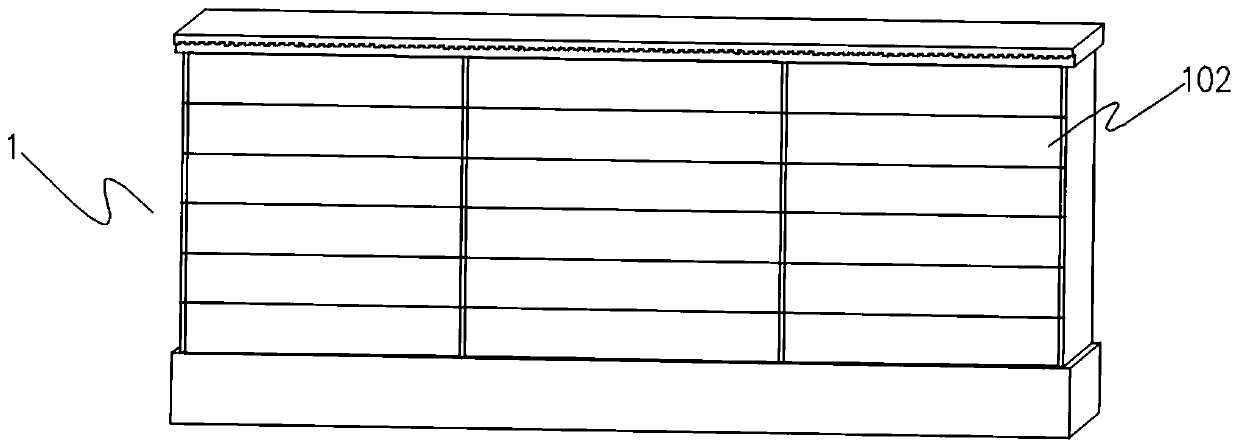

[0055] as attached Figure 1-2 As shown, a curing kiln for prefabricating interlocking sheets includes a plurality of curing chambers 1, a steam generator (not marked in the drawings) and a first controller.

[0056] The steam generator is arranged outside the curing room 1, the first controller is arranged on the outer wall of the curing room 1, and the plurality of curing rooms 1 are arranged side by side.

[0057] The number of the curing chambers 1 is at least 2 or more.

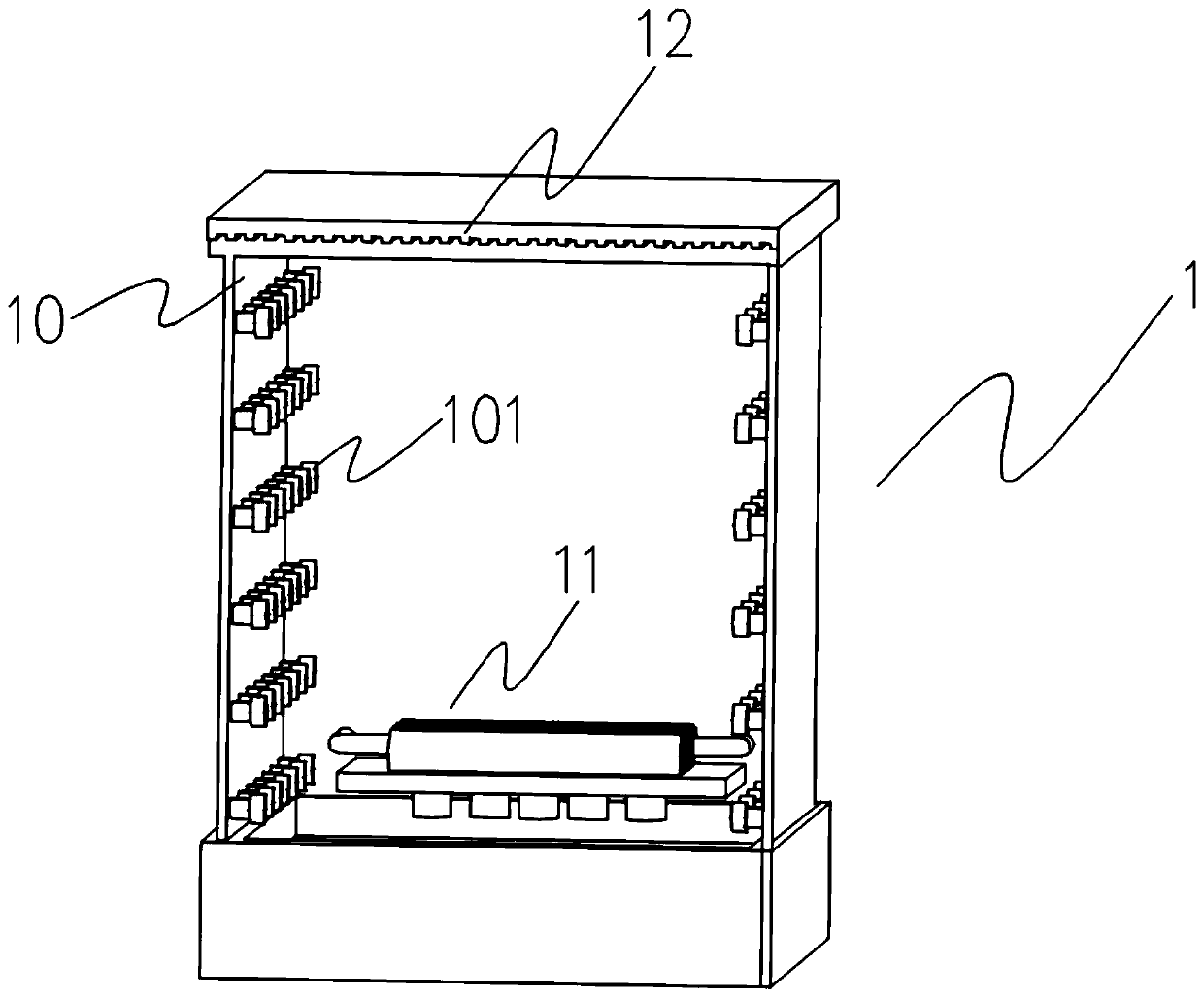

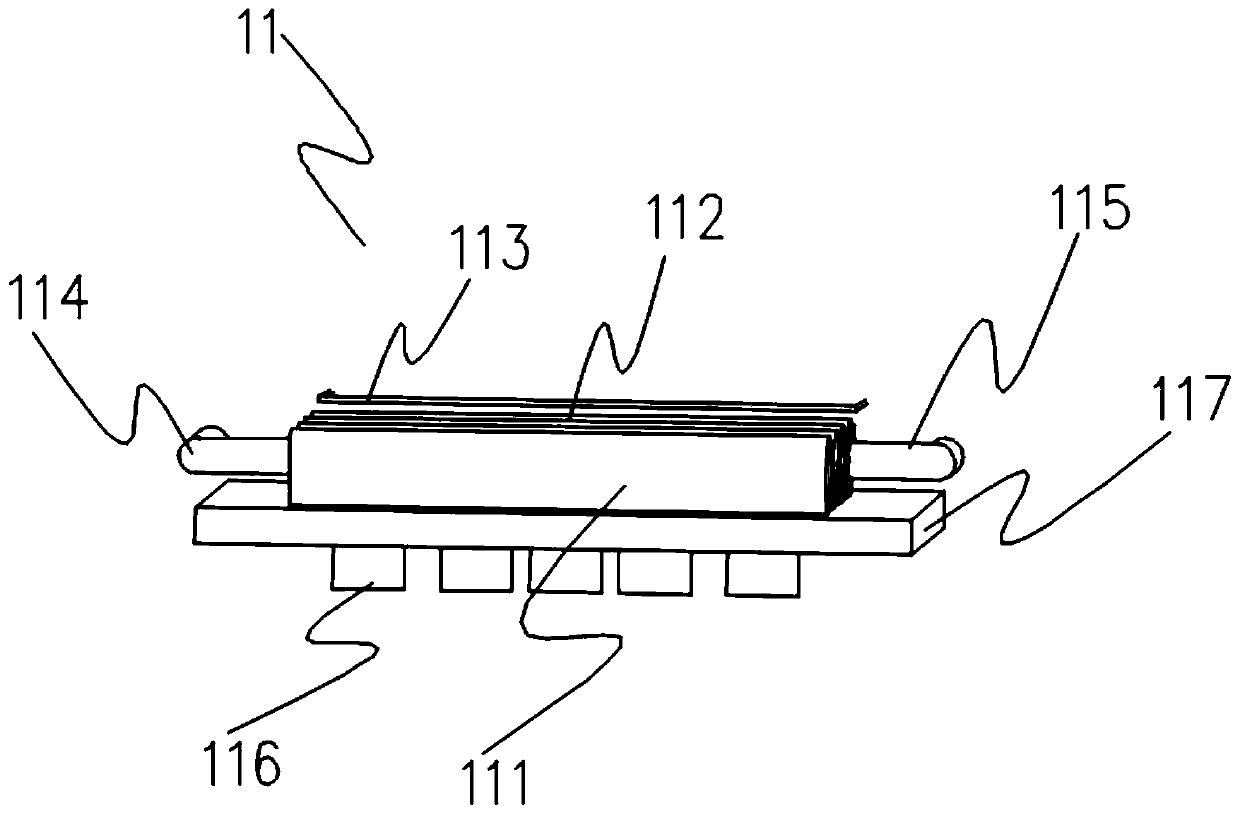

[0058] See attached figure 2 , a plurality of processing chambers 10 and heating devices 11 are arranged in each of the curing chambers 1, the processing chambers 10 are arranged in layers up and down, the heating devices 11 are arranged in the curing chamber 1, and the curing chamber 1 The temperature range within is 60-100°C.

[0059] The number of the processing chambers 10 is at least 2 or more.

[0060] Preferably, the heating device 11 is arranged below the inner space of the curing room 1 , a...

Embodiment 2

[0074] Based on the above-mentioned embodiment 1, the similarities will not be repeated, the difference is that, as attached Figure 5 As shown, the curing kiln also includes a lifting device 2, and the lifting device 2 is arranged outside the curing room 1; the lifting device 2 is used to transfer the interlocking sheet mold to be processed to the designated processing room 10 .

[0075] Preferably, curing chambers 1 are provided on both sides of the lifting device 2 to realize the transfer and processing of interlocking piece molds in the curing chambers 1 on both sides, which can improve the efficiency of mechanical transportation and save floor space.

[0076] as attached Figure 4 As shown, the lifting device 2 includes a second controller, a vertical frame 21, a loading platform 22, a top frame 23 and a lifting motor.

[0077] The lifting motor is connected to the second controller, and the second controller is a touch screen controller, which is convenient for setting...

Embodiment 3

[0088] Based on the above-mentioned embodiment 2, the similarities will not be repeated, the difference is that the curing kiln also includes a transmission track 3, and the transmission track 3 is arranged on the outside of the curing room 1; the transmission track 3 Used to transfer the interlocking piece molds to be processed to the curing area.

[0089] as attached Image 6 As shown, the transmission track 3 includes a support 31 , a transmission wheel 32 , and a driving motor, and the transmission wheel 32 is arranged on the support 31 .

[0090] Described transmission wheel 32 comprises driving wheel and driven wheel, and described driving wheel is connected with described driving motor, and described driving motor drives driving wheel to rotate, and described driving wheel and driven wheel are arranged at intervals on both sides, to realize interlocking piece The transfer movement of the mold.

[0091] The driving motor is connected with a switch, and the switch is us...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com