UV gloss oil capable of being used for rapid curing of UV-LED light source and preparation method of UV gloss oil

A UV-LED, rapid curing technology, applied in the direction of coating, etc., can solve the problems of poor UV varnish effect, low production efficiency, incomplete surface drying, etc., achieve high-tech value, improve production efficiency, and meet cleanliness and sanitation Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

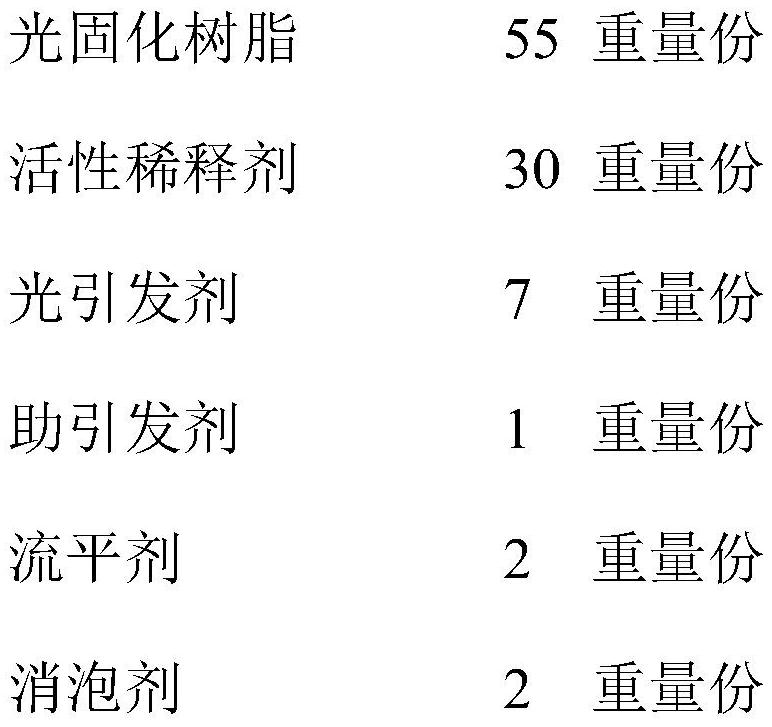

[0024] Embodiment 1: In this embodiment, UV varnish is prepared from the following raw materials in parts by weight:

[0025]

[0026] Among them, the photocurable resin is a mixture of hyperbranched acrylic resin and silicone urethane acrylate (the weight ratio of the two is 10:1), and the reactive diluent is diethylene glycol dimethacrylate, triethylene glycol dimethyl A mixture of acrylates (the weight ratio of the two is 2:3), the photoinitiator is a mixture of TPO, photoinitiator TEPO, and photoinitiator 819 (the weight ratio of the three is 1:1:1), defoamer and fluid The leveling agent is produced by BYK.

[0027] The preparation method comprises the following steps:

[0028] (1) Add active diluent, photoinitiator, co-initiator, defoamer and leveling agent into the stirring pot by weight for pre-dispersion, stir evenly, stirring speed 700r / min, stirring time 25min;

[0029] (2) Add hyperbranched acrylic resin and organosilicon urethane acrylate in parts by weight in...

Embodiment 2

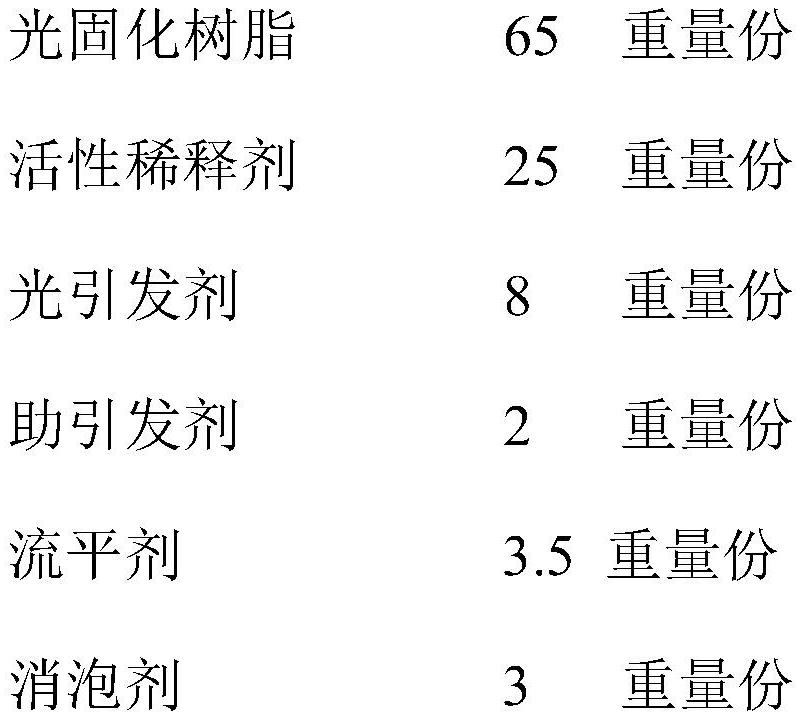

[0030] Embodiment 2: In this embodiment, the UV varnish is prepared from the following raw materials in parts by weight:

[0031]

[0032] Wherein, the photocurable resin is a mixture of hyperbranched acrylic resin and silicone urethane acrylate (the weight ratio of the two is 10:3), and the reactive diluent is a mixture of diethylene glycol dimethacrylate and tripropylene glycol diacrylate (The weight ratio of the two is 3:1), the photoinitiator TPO and the photoinitiator TEPO (the weight ratio of the two is 1:1), and the defoamer and leveling agent are produced by Digao.

[0033] The preparation method comprises the following steps:

[0034] (1) Add the active diluent, photoinitiator, co-initiator, defoamer and leveling agent into the stirring pot by weight for pre-dispersion, stir evenly, the stirring speed is 550r / min, and the stirring time is 28min;

[0035] (2) Add hyperbranched acrylic resin and organosilicon urethane acrylate in parts by weight in the stirring pot,...

Embodiment 3

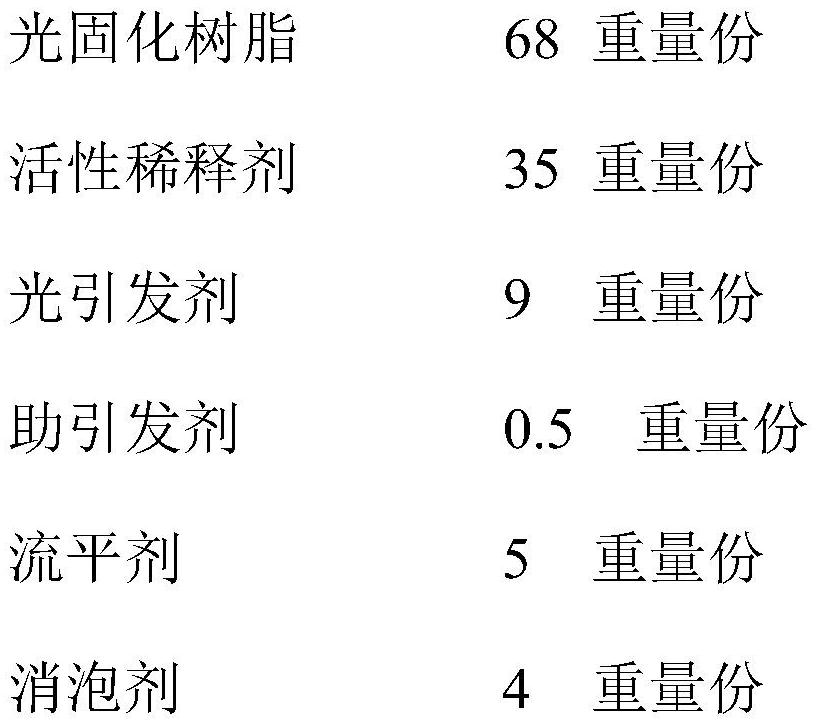

[0036] Embodiment three: In this embodiment, UV varnish is prepared from the following raw materials in parts by weight:

[0037]

[0038] Wherein, the photocurable resin is a mixture of hyperbranched acrylic resin and silicone urethane acrylate (the weight ratio of the two is 12:5), and the reactive diluent is triethylene glycol dimethacrylate, photoinitiator TPO and photoinitiator The mixture of ITX (the weight ratio of the two is 1:1), the defoamer and the leveling agent are produced by Tego.

[0039] The preparation method comprises the following steps:

[0040] (1) Add reactive diluent, photoinitiator, co-initiator, defoamer and leveling agent into the stirring pot by weight for pre-dispersion, stir evenly, stirring speed 600r / min, stirring time 26min;

[0041] (2) Add hyperbranched acrylic resin and organosilicon urethane acrylate in parts by weight in the stirring pot, mix and stir evenly, stirring speed 1200r / min, stirring time 105min, filter with 350 mesh filter b...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com