Ultrasonic welding machine assembly

An ultrasonic welding and assembly technology, applied in welding equipment, non-electric welding equipment, metal processing equipment, etc., to achieve the effect of adapting to large-scale production, ensuring quality and improving shape

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] The present invention is described in detail below in conjunction with accompanying drawing:

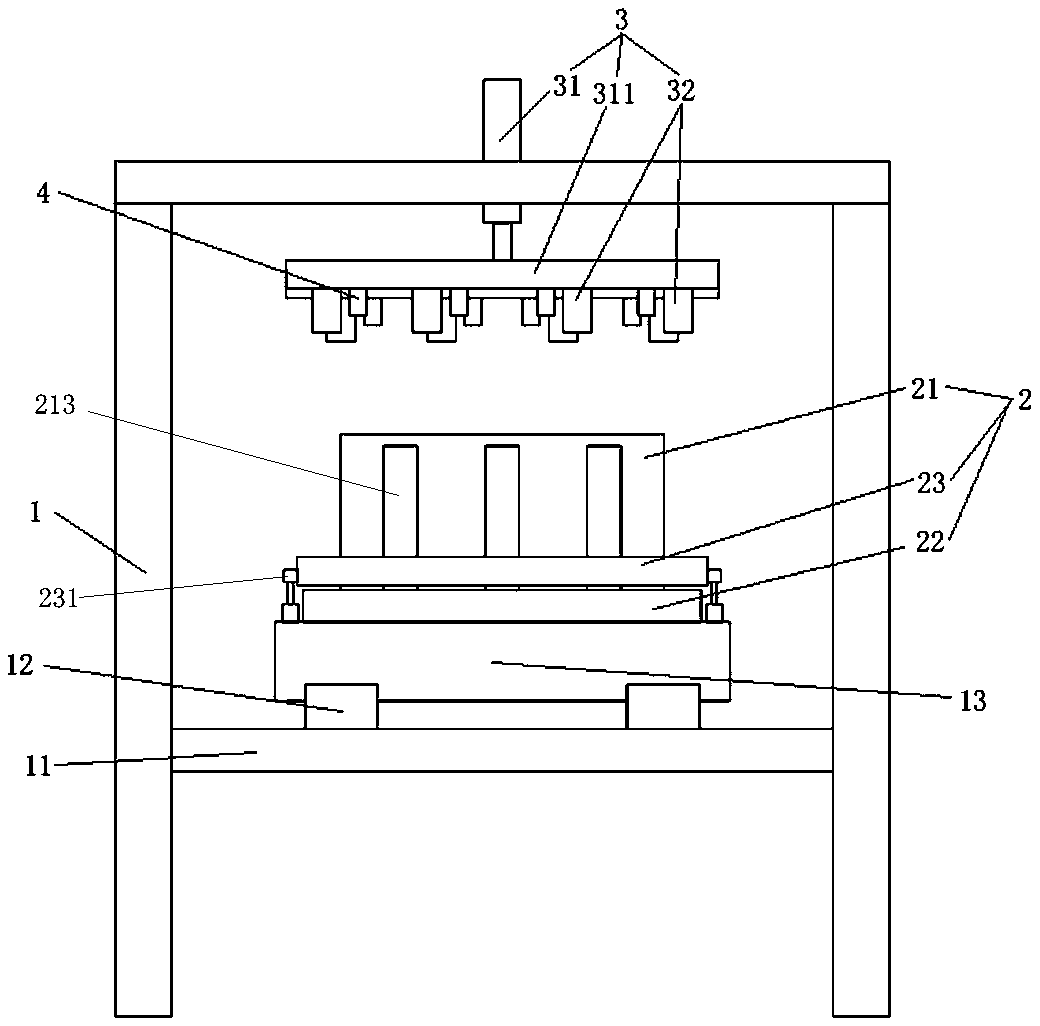

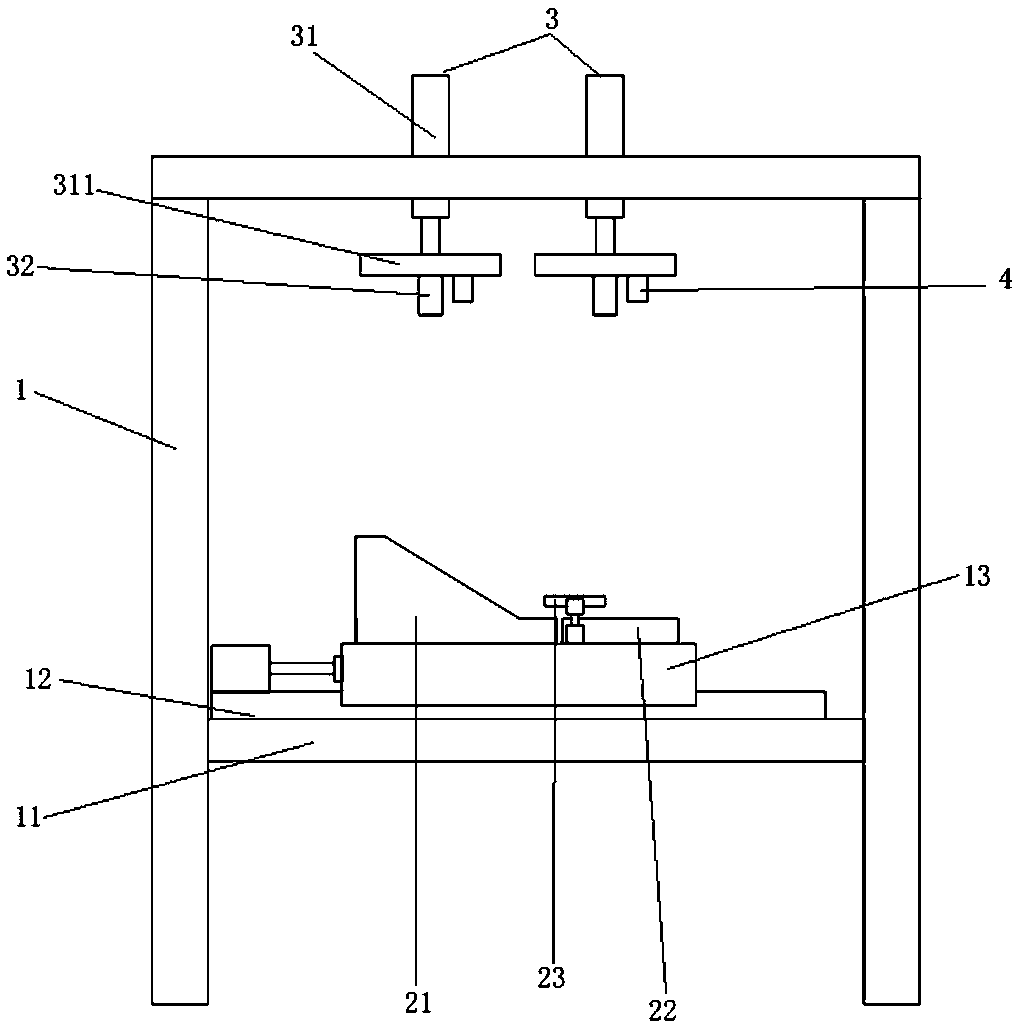

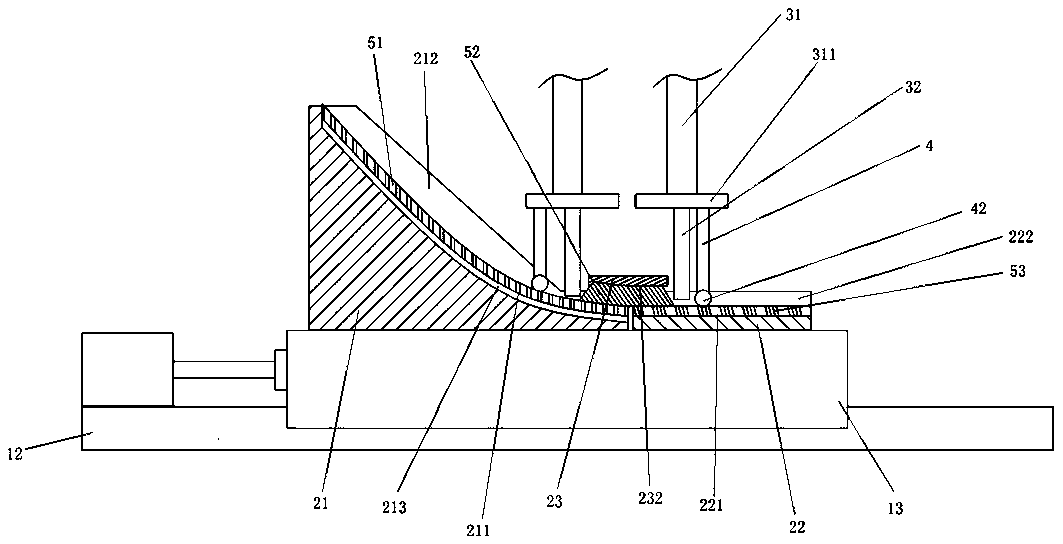

[0027] like figure 1 , 2 . An ultrasonic welding machine assembly shown in 3 includes a frame-type frame 1, each side of the frame 1 has detachable baffles, and the bottom of the frame 1 is equipped with universal wheels. The middle part of the frame 1 is supported by a bolt head to install a support plate 11, and two parallel slide rails 12 are connected by bolts on the support plate 11. The slide rail 12 has a slide seat 13 that can move along the slide rail 12, and the slide seat 13 passes through the The cylinder realizes the relative sliding between the slide rail 12. When installing the components to be welded, it can slide forward to facilitate the installation of workers or manipulators. After the installation is completed, slide backward to the welding assembly 3 for welding. Fine-tuning when welding components to be welded. Bolts on the sliding seat 13 are connect...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com