Flexible multifunctional vacuum coating equipment and its intelligent control system

A vacuum coating, multi-functional technology, applied in vacuum evaporation coating, sputtering coating, ion implantation coating and other directions, can solve the problem of single structure and function, and achieve the effect of ensuring stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment 1

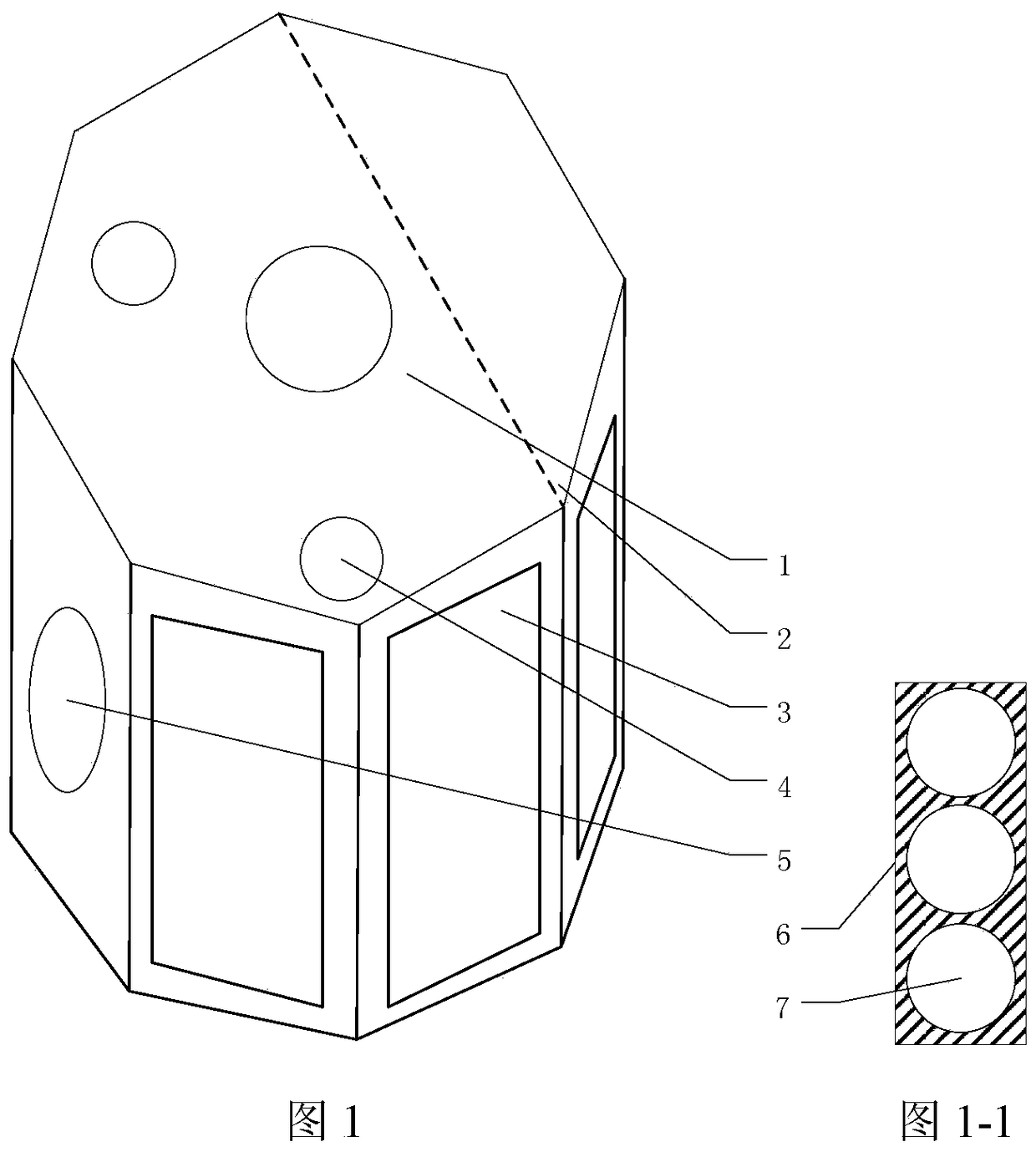

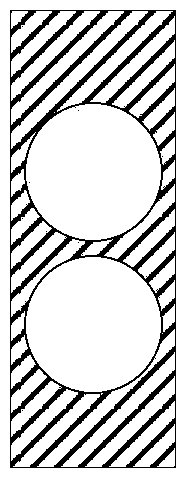

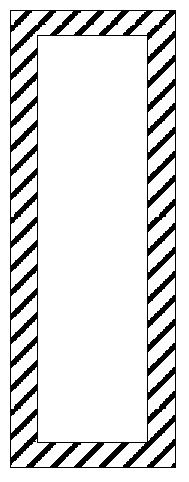

[0038] refer to figure 1 , the flexible modular multifunctional plasma coating equipment involved in this embodiment, its vacuum chamber 1 is an equilateral octagonal prism-shaped sealing structure, surrounded by a vacuum chamber door 2 and a plurality of rectangular facades of different forms and uses Formed, and its center forms a sealed cavity; the side wall of the vacuum chamber 1 is composed of several rectangular facades, one of which is provided with a vacuum obtaining equipment connection port 5, and the other facades are respectively provided with a rectangular flange hole 3. The rectangular flange hole 3 is provided with an easy-to-assemble and disassemble rectangular flange plate 6, and the rectangular flange plate 6 is provided with one or more than two target connecting holes 7, forming a flexible connection mechanism; the vacuum chamber door 2 includes a Or two or more facades, each facade is provided with a rectangular flange hole 3, a rectangular flange plate 6...

specific Embodiment 2

[0061] refer to figure 2 , the characteristics of this embodiment 2 are: the sealing structure when the vacuum chamber 1 is cylindrical, the vacuum chamber door 2 and the center of the vacuum chamber 1 form a sealed cavity; the side elevation of the vacuum chamber 1 is provided with a vacuum obtaining equipment connection port 5. One or more rectangular flange holes 3 are provided at the remaining positions, and a rectangular flange plate 6 is provided at the rectangular flange hole 3, and one or more than two target connecting holes 7 are arranged in the rectangular flange plate 6, A flexible connection mechanism is formed; the facade of the vacuum chamber door 2 can also be provided with a rectangular flange hole as required, and a rectangular flange plate 6 is provided at the rectangular flange hole 3, and a rectangular flange plate 6 is provided with one or More than two target base connection holes 7 form a flexible connection mechanism; through the target base connectio...

specific Embodiment 3

[0062] refer to Figure 4 , the characteristics of the present embodiment 3 are: the facade of the vacuum chamber 1 and the vacuum chamber door 2 form an equilateral octagonal prism structure, wherein three sides constitute the vacuum chamber door 2, and one side of the vacuum chamber is provided with a vacuum obtaining equipment connection The other six sides are provided with rectangular flange holes for installing the rectangular flange plate 6. Two rectangular flange plates opposite to each other form a group, each of the first group of rectangular flange plates is provided with a circular target seat connecting hole for installing the anode target 14; each of the second group of rectangular flange plates is provided with two The connecting holes of the circular target base are used for installing the cathode target 8; the third group of rectangular flange plates are respectively provided with three connecting holes of the circular target base for installing the cathode ta...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com