Batching disc for watch outer shells

A technology of appearance and watches, which is applied in the direction of transportation, packaging, conveyors, etc., can solve the problems of the small number of processed parts and the inability to meet mass production, and achieve the effect of good accuracy and improved work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

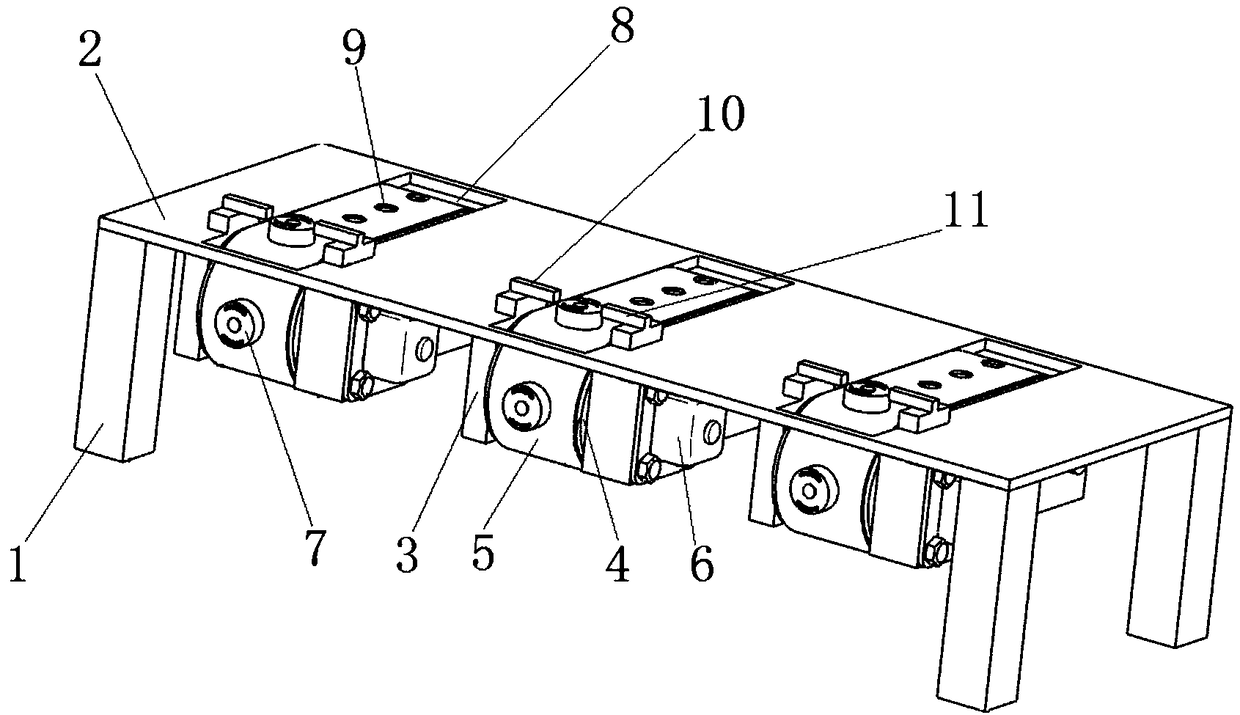

[0025] like figure 1 The shown batching tray for the outer case of a watch includes a batching tray support 1, a worktable 2 arranged on the batching tray support 1, and a plurality of batching mechanisms sequentially arranged on the worktable 2 along the length direction of the worktable 2 , The workbench 2 is provided with a detection mechanism compatible with the batching mechanism.

[0026] Wherein, batching mechanism comprises the installation frame 3 that is arranged on the bottom of workbench 2, a pair of pulleys 4 that are arranged side by side on the installation frame 3, the conveyor belt 5 that is wound between two pulleys 4, is arranged on the installation frame 3 and A stepper motor 6 connected to the pulley 4 and a plurality of parts trays 7 sequentially arranged on the conveyor belt 5 along the length direction of the conveyor belt 5 . The workbench 2 is provided with a conveyor belt relief port 8 adapted to the conveyor belt 5 . Conveyor belt give way mouth 8...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com