Surface treatment method of printed circuit board and application of surface treatment method

A printed circuit board, surface treatment technology, applied in the direction of printed circuit, printed circuit manufacturing, electrical components, etc., can solve the problems of ink loss and residual glue, seepage, difficult to meet product requirements, etc., to achieve easy film fading, adhesion Tight, little pollution effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0062] A method for making a PCB, the specific process is:

[0063] Pre-process→solder resist→characters→wet film selection→anti-electric gold tape→laser cutting→nickel gold electroplating→film removal→etching→electric gold tape tearing→wet film selection→chemical nickel gold→film removal→after process .

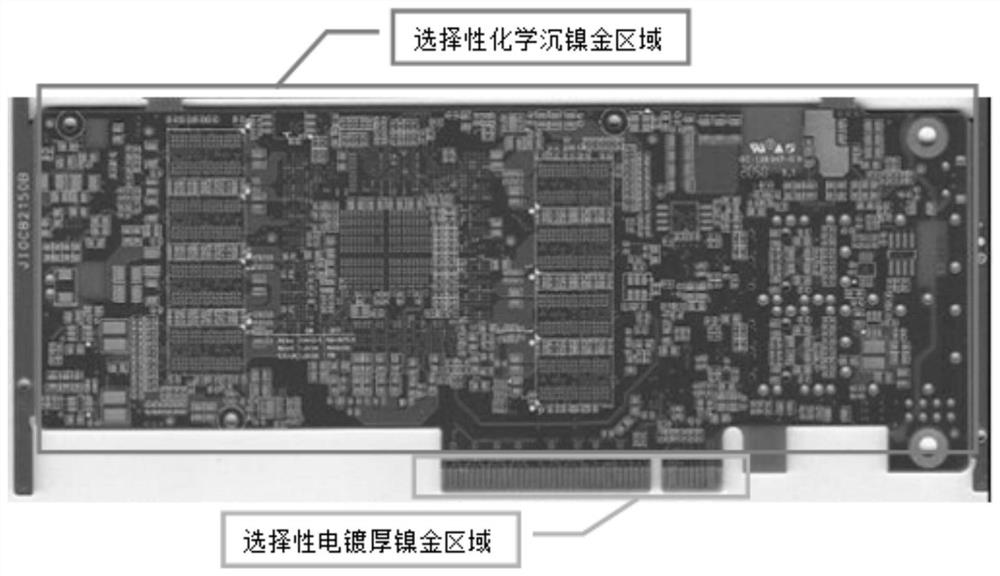

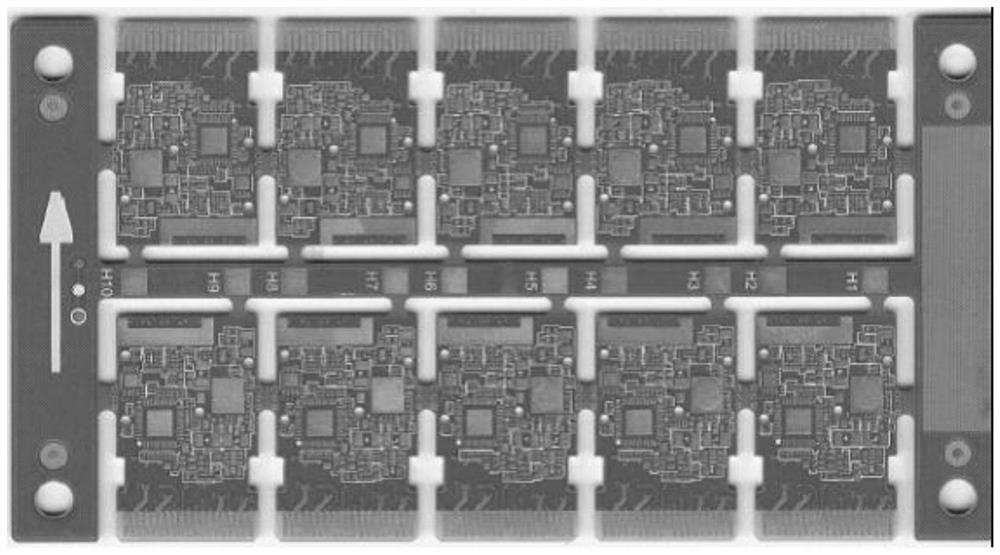

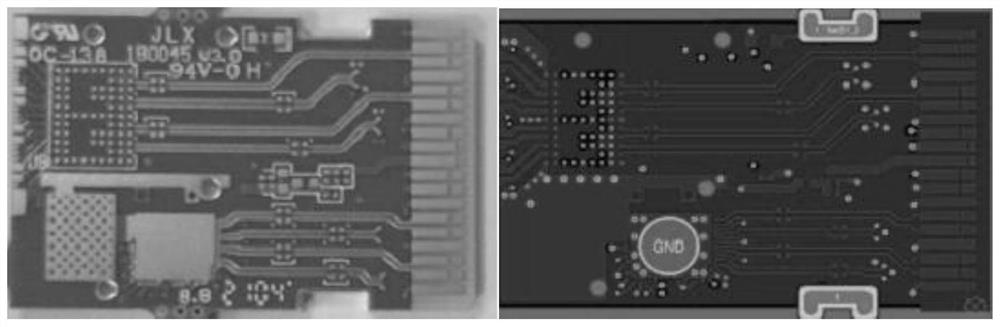

[0064] Specifically, after the pre-production process (pre-process) such as material cutting, inner layer dry film, browning, lamination, drilling, copper plate plating, outer layer dry film, outer layer graphic plating, etc. (it can also be used) character making), and obtain the PCB with the outer layer circuit and the solder resist layer made. After the pre-processing process, the outer circuit in the PCB includes the gold finger area for selective electroplating of thick nickel gold, and the leads drawn from the gold finger area to the edge of the printed circuit board are used for selective electroless nickel gold plating. The chemical immersion gold area, and the rem...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Adhesion | aaaaa | aaaaa |

| Adhesion | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com