Patents

Literature

87results about How to "Affect adhesion" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

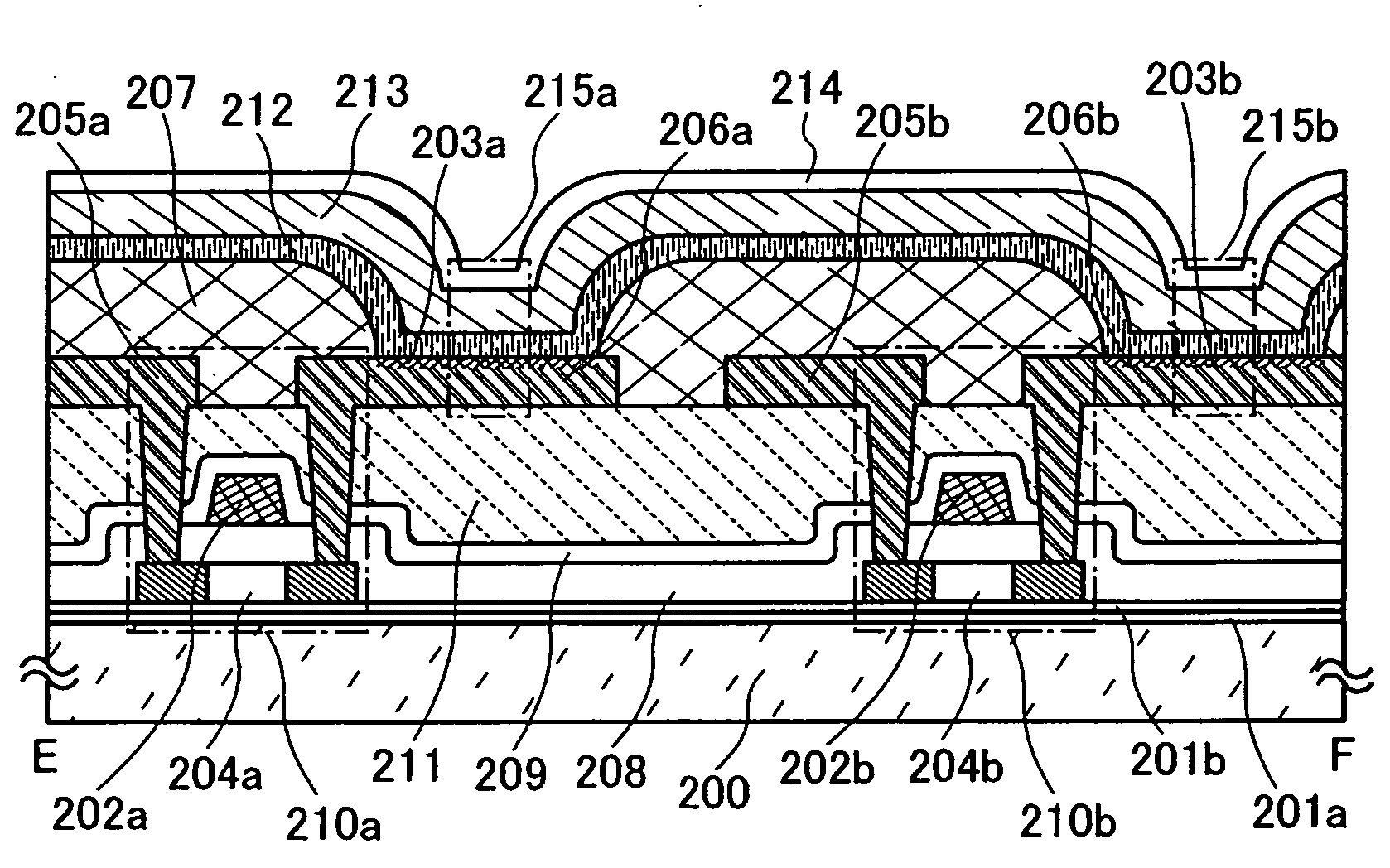

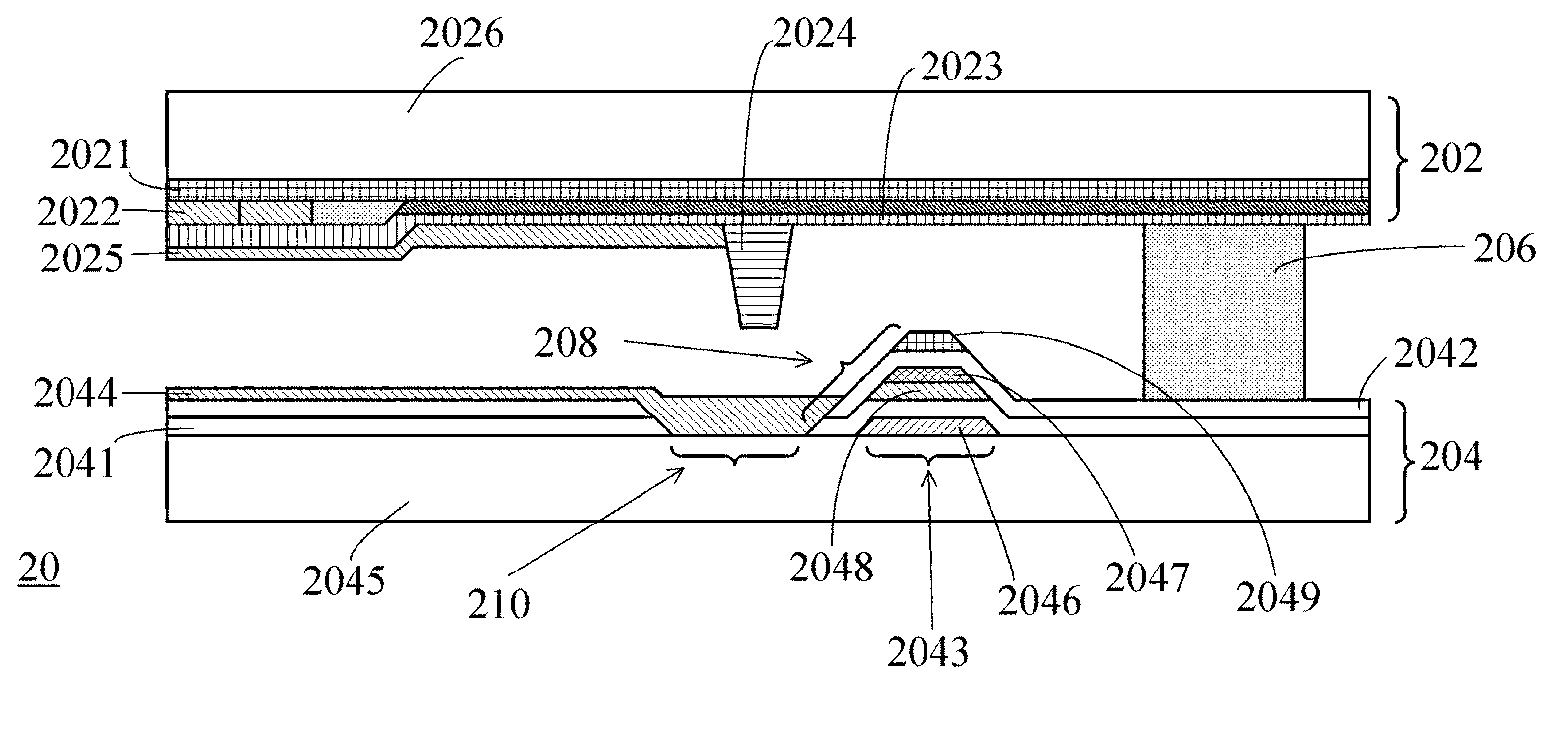

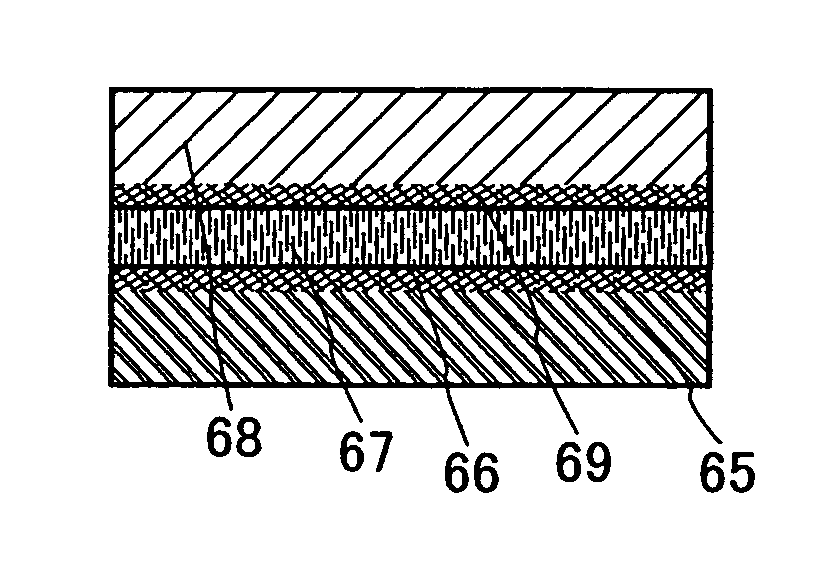

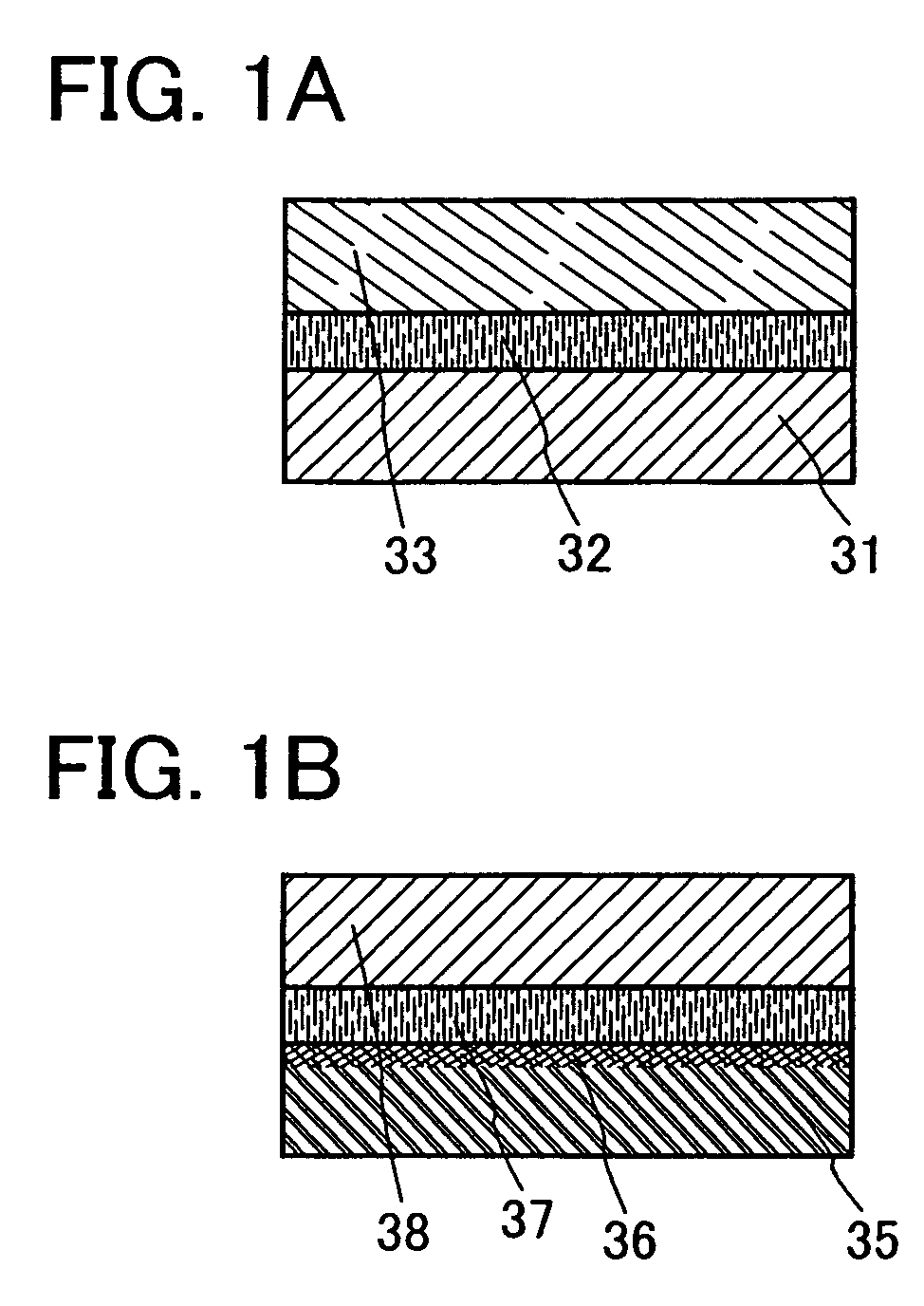

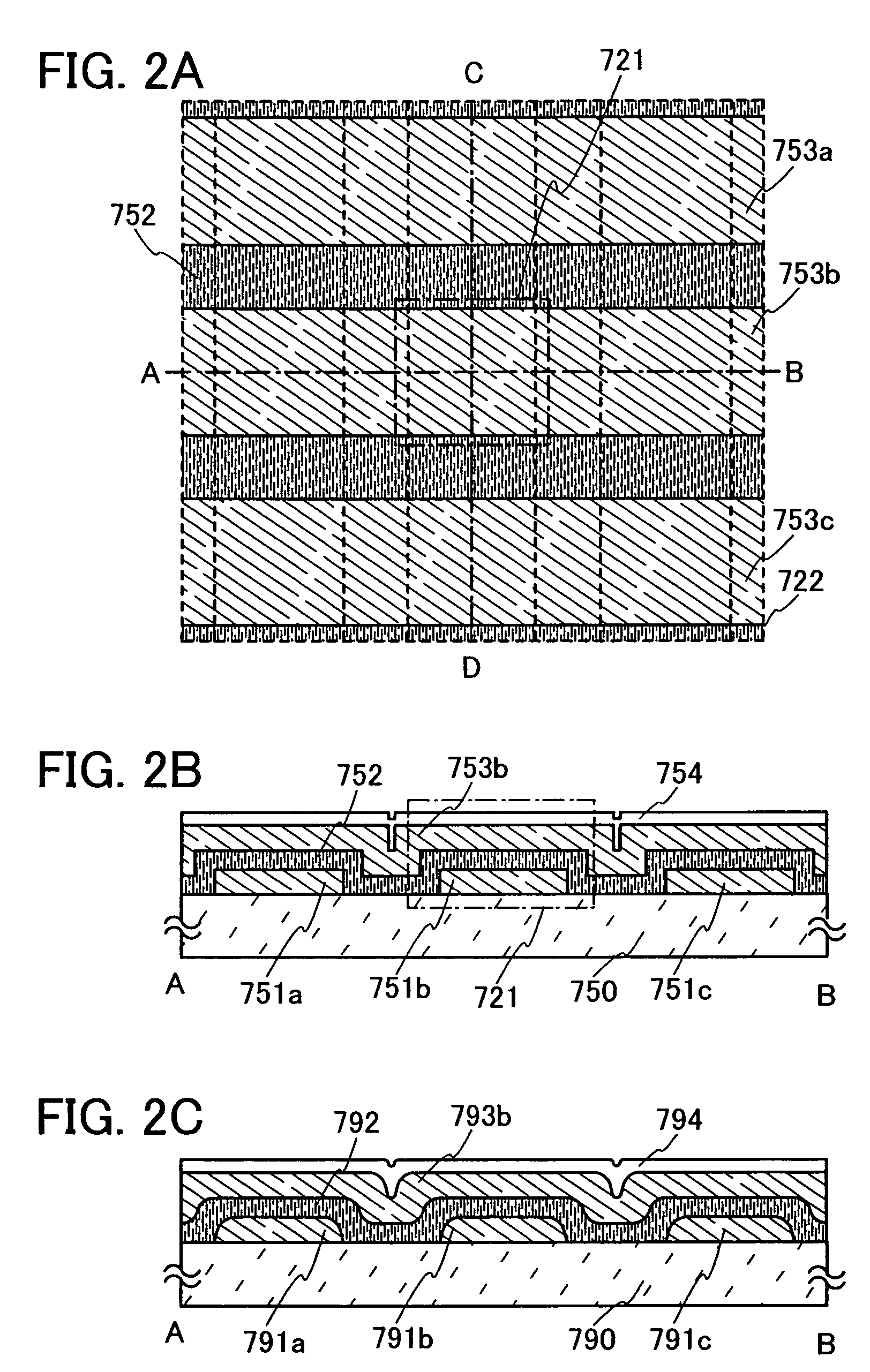

Semiconductor device and manufacturing method thereof

InactiveUS20070105285A1Improve adhesionExcellent stateNanoinformaticsSolid-state devicesIndiumOrganic compound

To provide a semiconductor device which is higher functional and reliable and a technique capable of manufacturing the semiconductor device with a high yield at low cost without complexing the apparatus or process. At least one of a first conductive layer and a second conductive layer is formed containing one kind or plural kinds of indium, tin, lead, bismuth, calcium, manganese, or zinc; or oxidation treatment is performed at least one of interfaces between an organic compound layer and the first conductive layer and between the organic compound layer and the second conductive layer. The first conductive layer, the organic compound layer, and the second conductive layer which are formed over a first substrate with a peeling layer interposed therebetween can be peeled from the first substrate with the peeling layer, and transposed to a second substrate.

Owner:SEMICON ENERGY LAB CO LTD

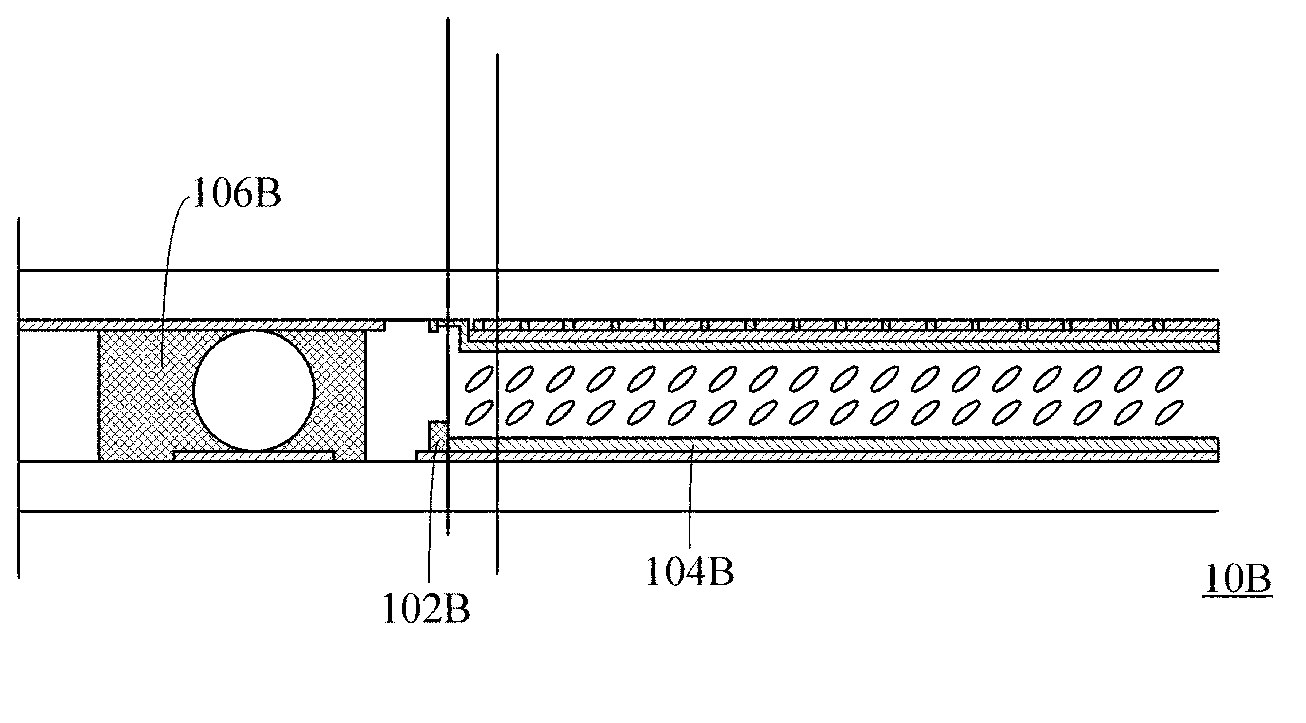

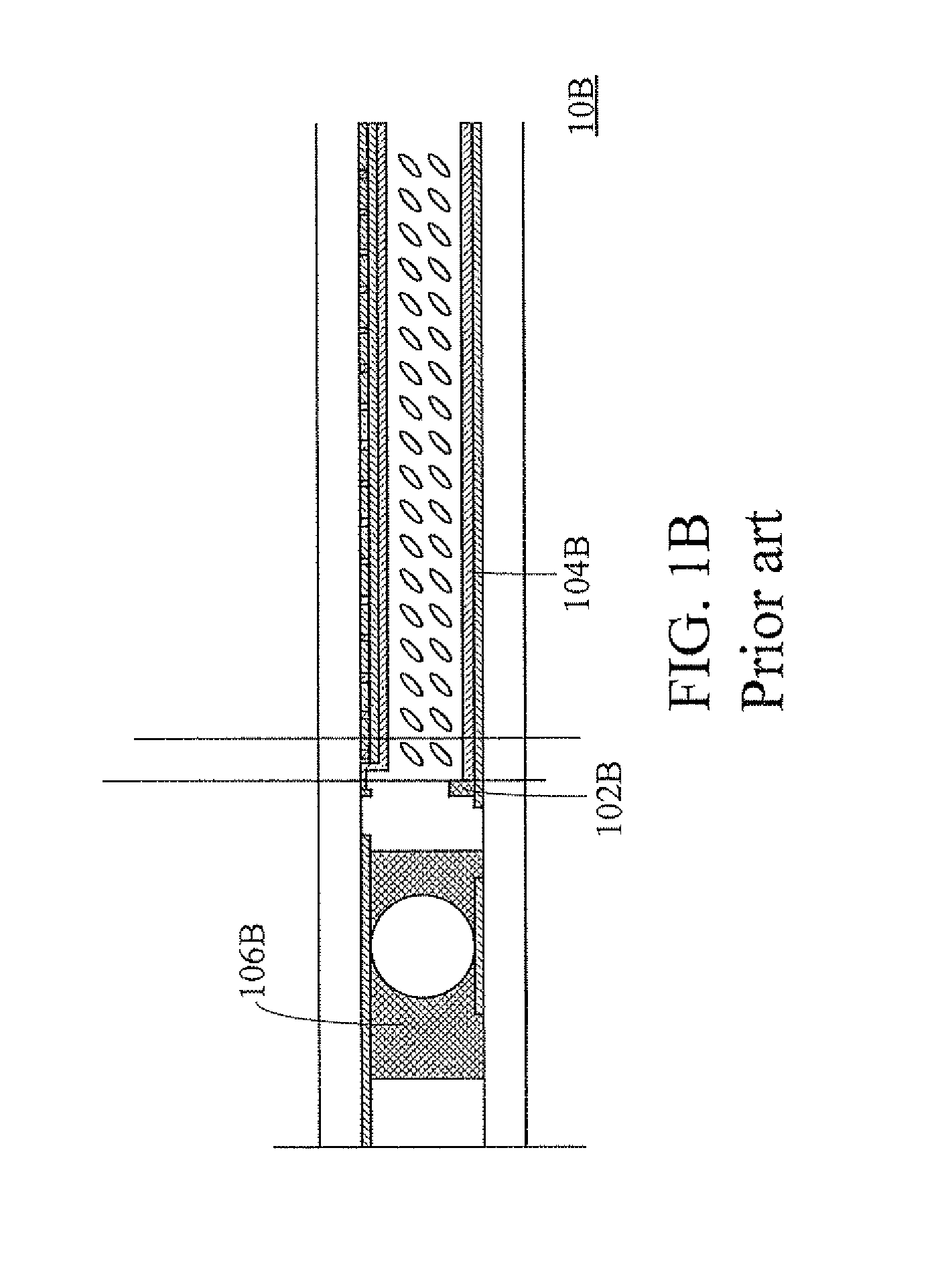

Liquid crystal panel and manufacturing method thereof

The invention provides a liquid crystal panel, which comprises an upper substrate, a lower substrate and frame glue, wherein the lower substrate comprises a display area, a non-display area, a first limiting component and a second limiting component; the non-display area is adjacent to the display area; and the frame glue is arranged on the non-display area; the first limiting component is located at edge of the non-display area; the second limiting component is located between the display area and the first limiting component. By virtue of combination of the first limiting component and the second limiting component, when an alignment film is coated on the lower substrate, the alignment film is not expanded to the non-display area.

Owner:TCL CHINA STAR OPTOELECTRONICS TECH CO LTD

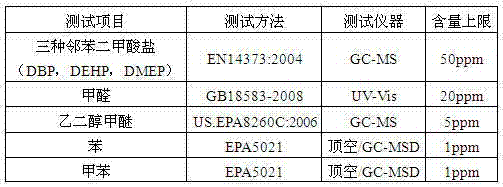

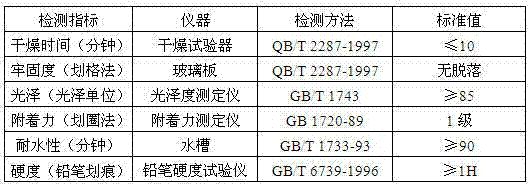

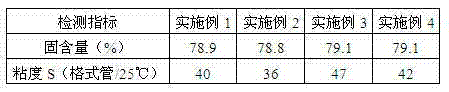

Preparation method of alkyd resin

InactiveCN102408551AImprove adhesionFullnessCosmetic preparationsToilet preparationsPolymer scienceNitrocellulose

The invention relates to a preparation method of alkyd resin. The preparation method comprises the following specific steps: (1) adding neopentyl glycol, trihydroxymethyl propane, phthalic anhydride, hydrogenated phthalic anhydride and antioxidant to a reaction container, and heating to carry out melt esterification on the materials at the temperature of 200-240 DEG C; (2) when esterification is carried out to an acid value being 40-45 mgKOH / g, cooling to 120-160 DEG C, and adding short-chain synthetic fatty acid and an aliphatic hydrocarbon solvent; (3) heating to carry out reflux esterification at the temperature of 180-200 DEG C, and diluting with acetic acid ester organic solvent when the acid value is smaller than or equal to 8 mgKOH / g; and (4) cooling to 100 DEG C and filtering to obtain alkyd resin. The paint prepared from the alkyd resin obtained in the invention and nitrocellulose has the characteristics of rapid drying, high hardness, good fullness, good adhesion force, and good water resistance.

Owner:JIANGSU SANMU GROUP CORPORATION

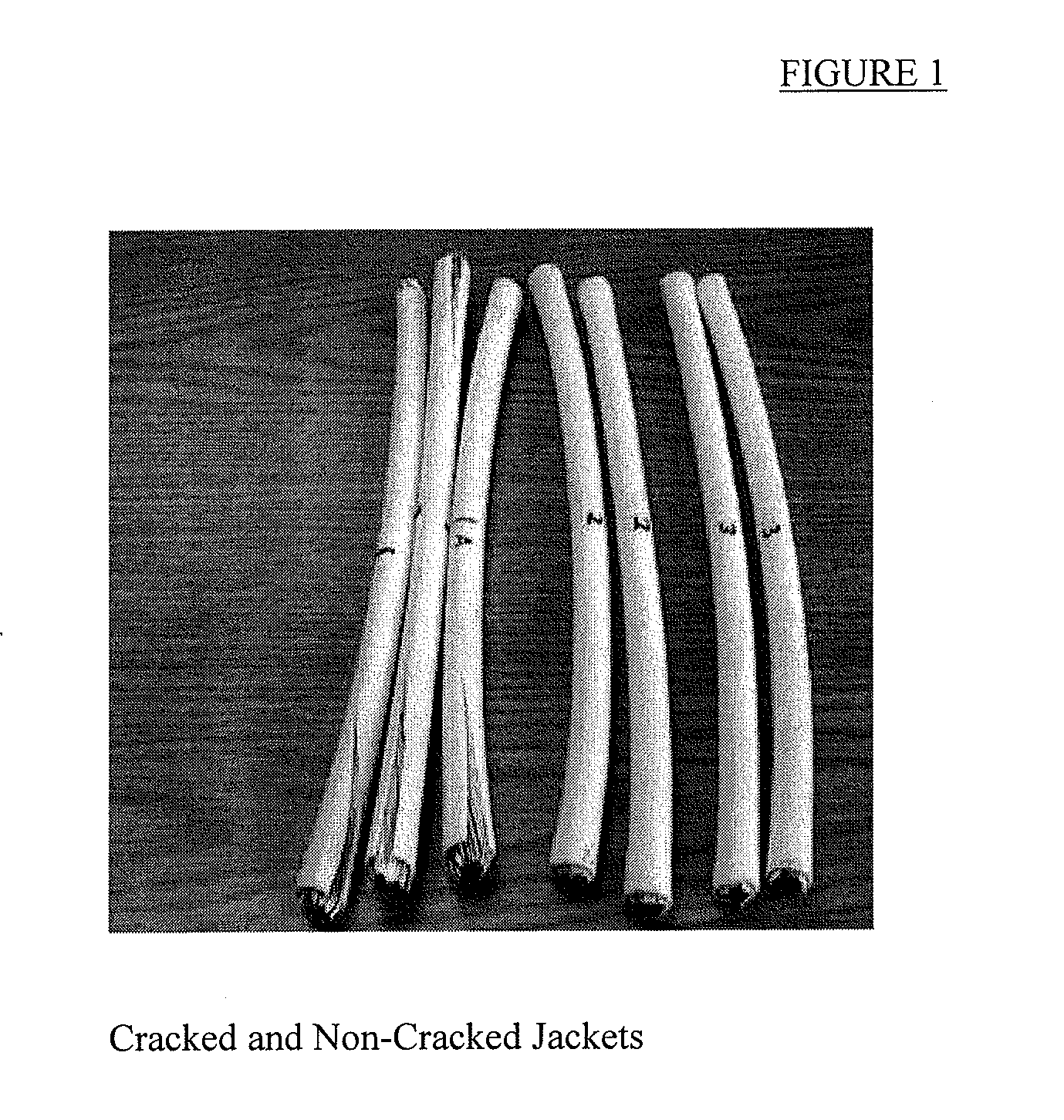

Crack-Resistant, Flame Retardant, Halogen-Free, Cable Assembly and Coating Composition

ActiveUS20100069545A1Affect adhesionImproved propertyLiquid surface applicatorsSpecial tyresMaleic anhydrideChemistry

Halogen-free, flame-retardant, crack-resistant, cable coatings are prepared from a composition comprising:A) 3 to 10 percent by weight of a low-melting temperature and medium to high grafted level maleic anhydride grafted polyethylene using a VLDPE base resin having density ranging from 0.86 to 0.91 g / cm3 and made with a single-site catalyst;B) 15 to 25% by weight of at least one EEA or EVA;C) 5 to 20% by weight of an a-olefin polymer; andD) 40 to 65% by weight of a flame retardant inorganic filler.

Owner:UNION CARBIDE CORP

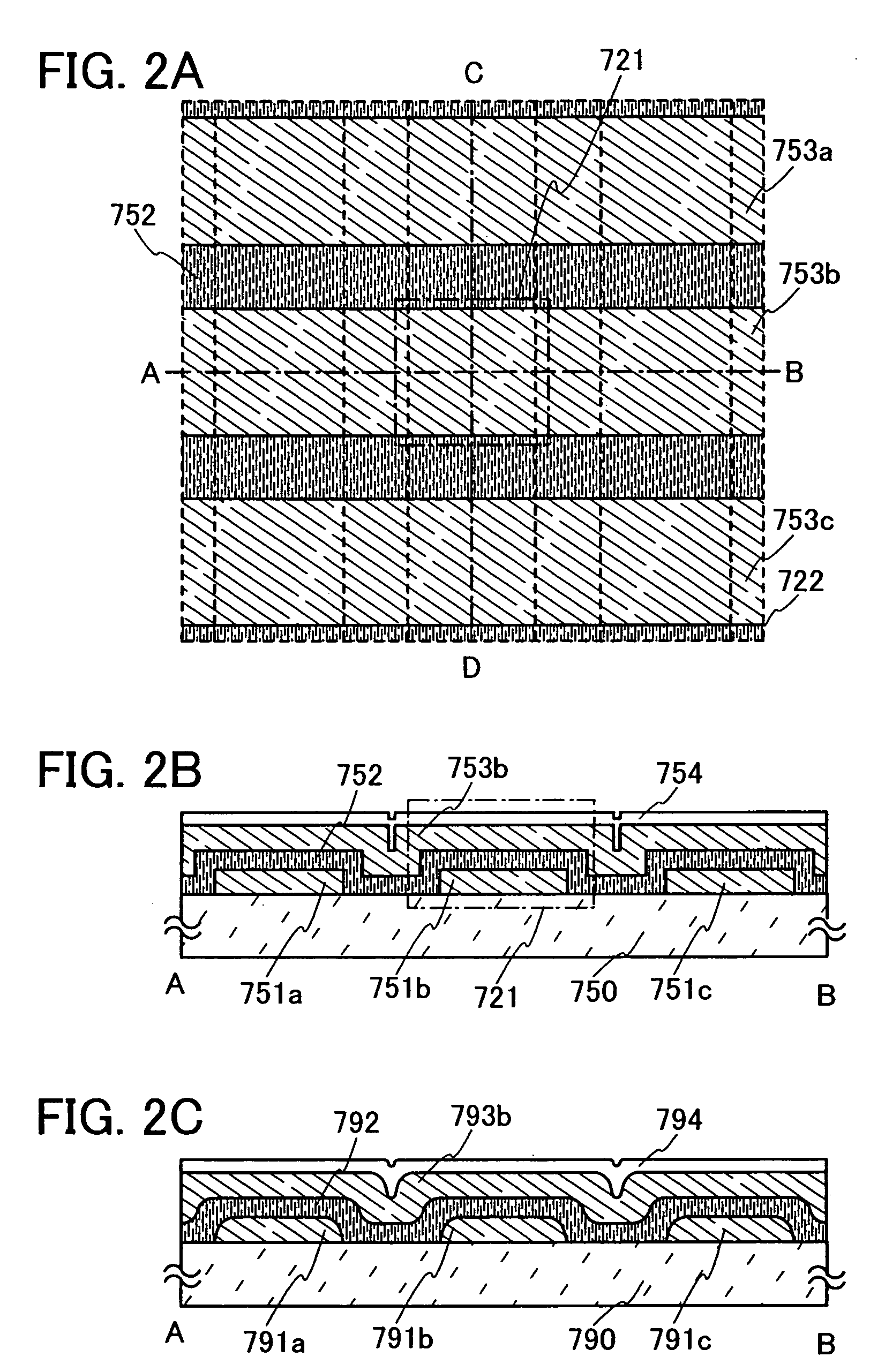

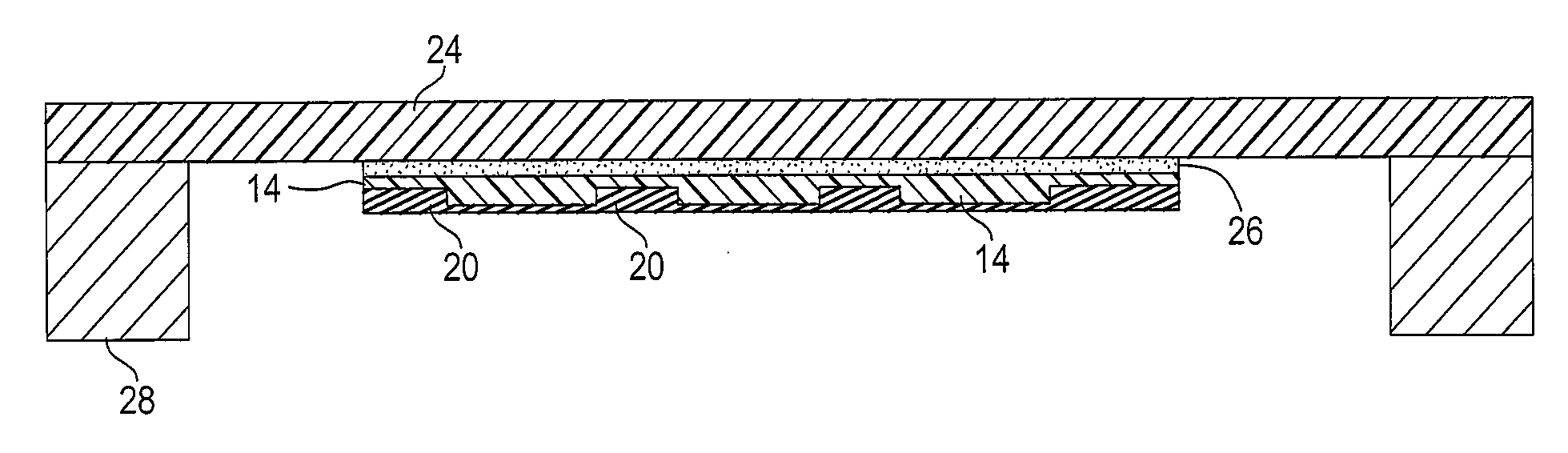

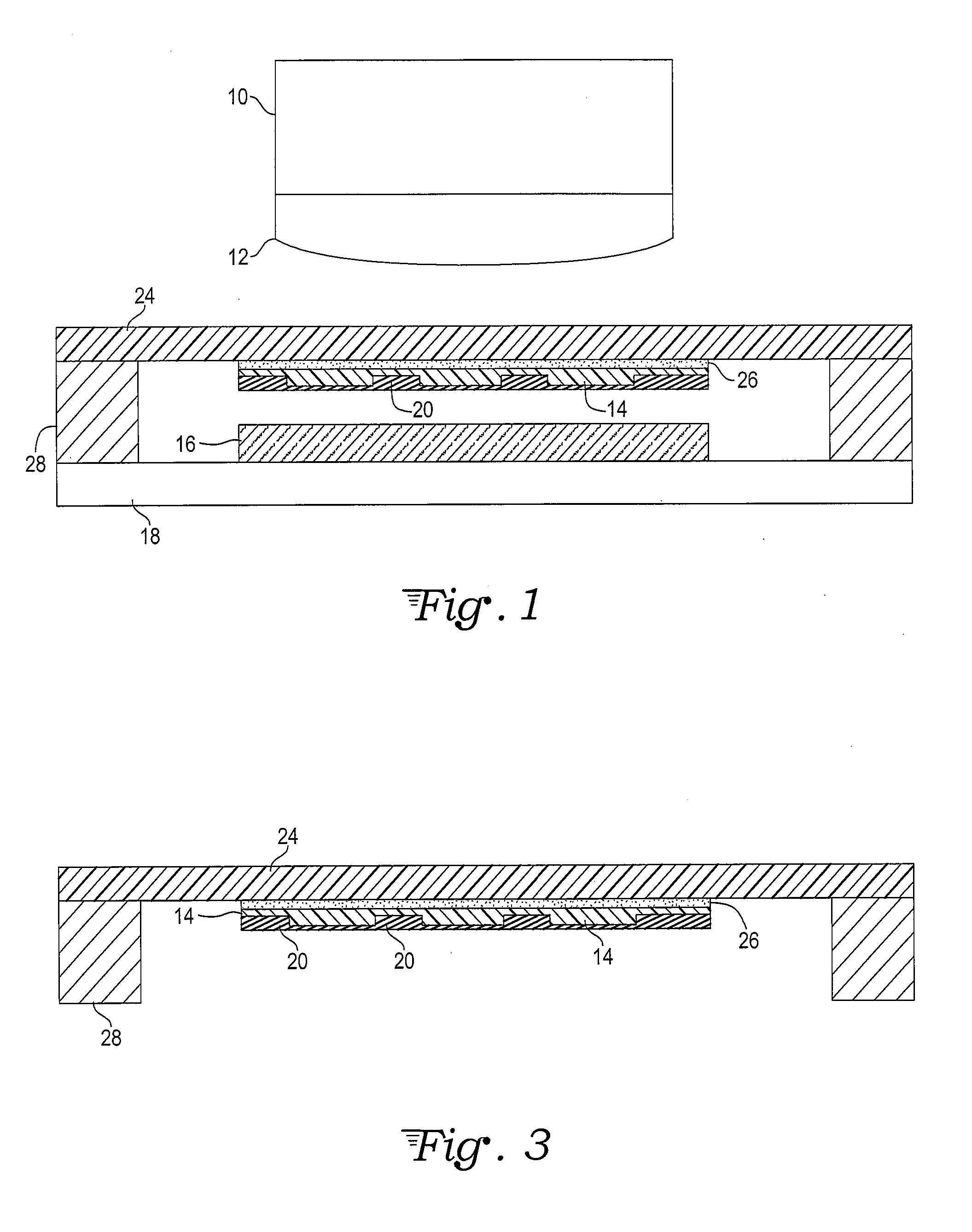

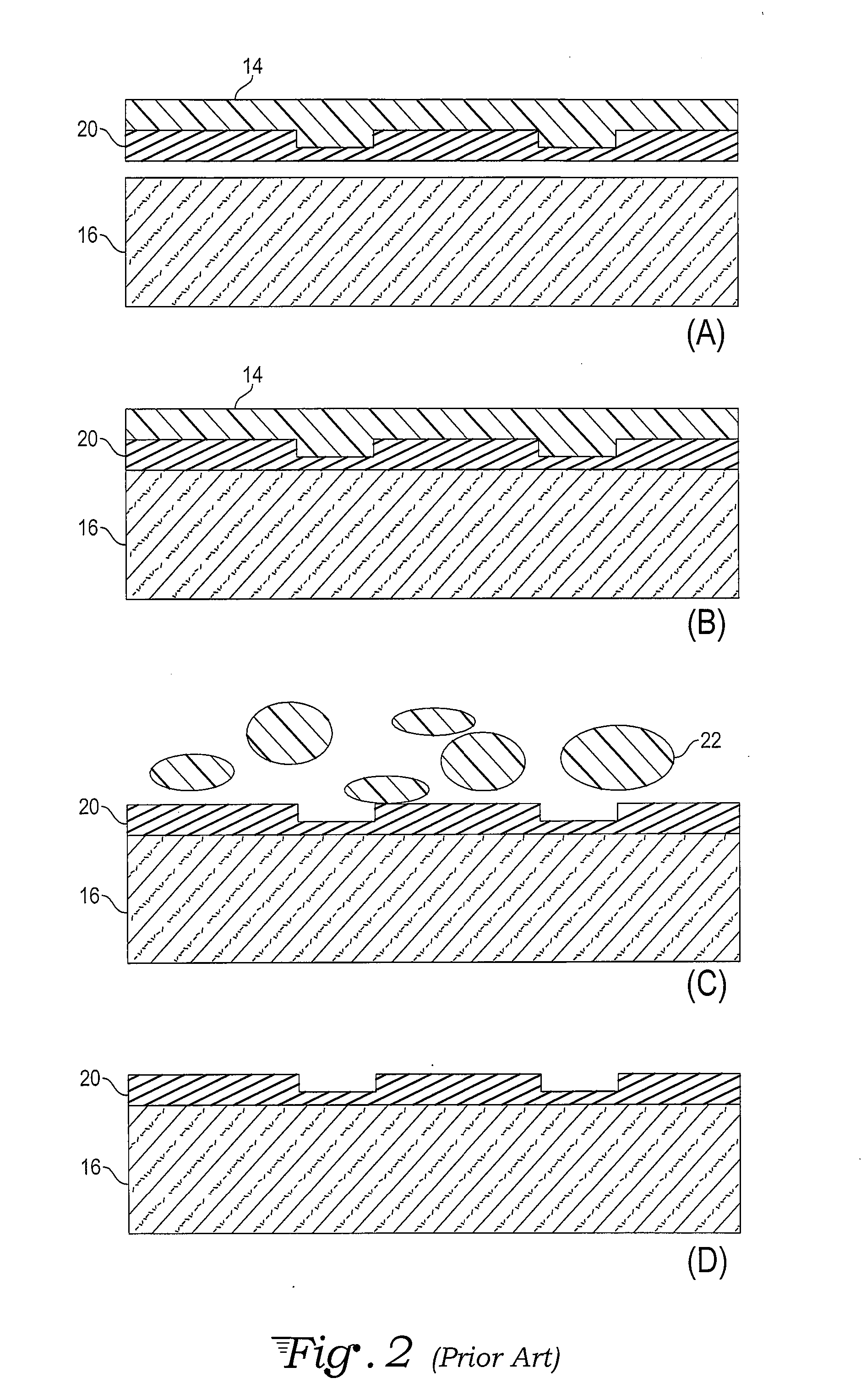

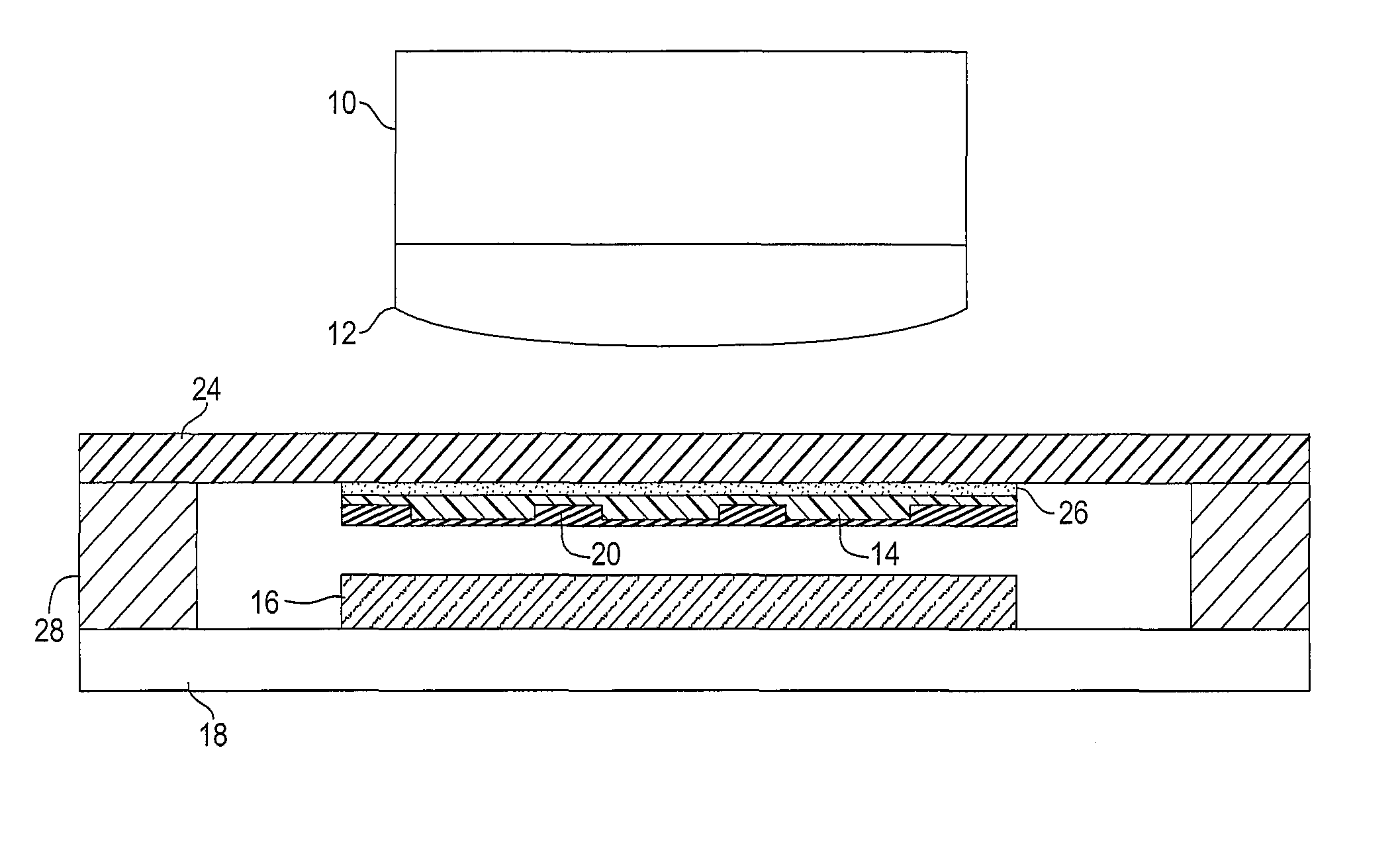

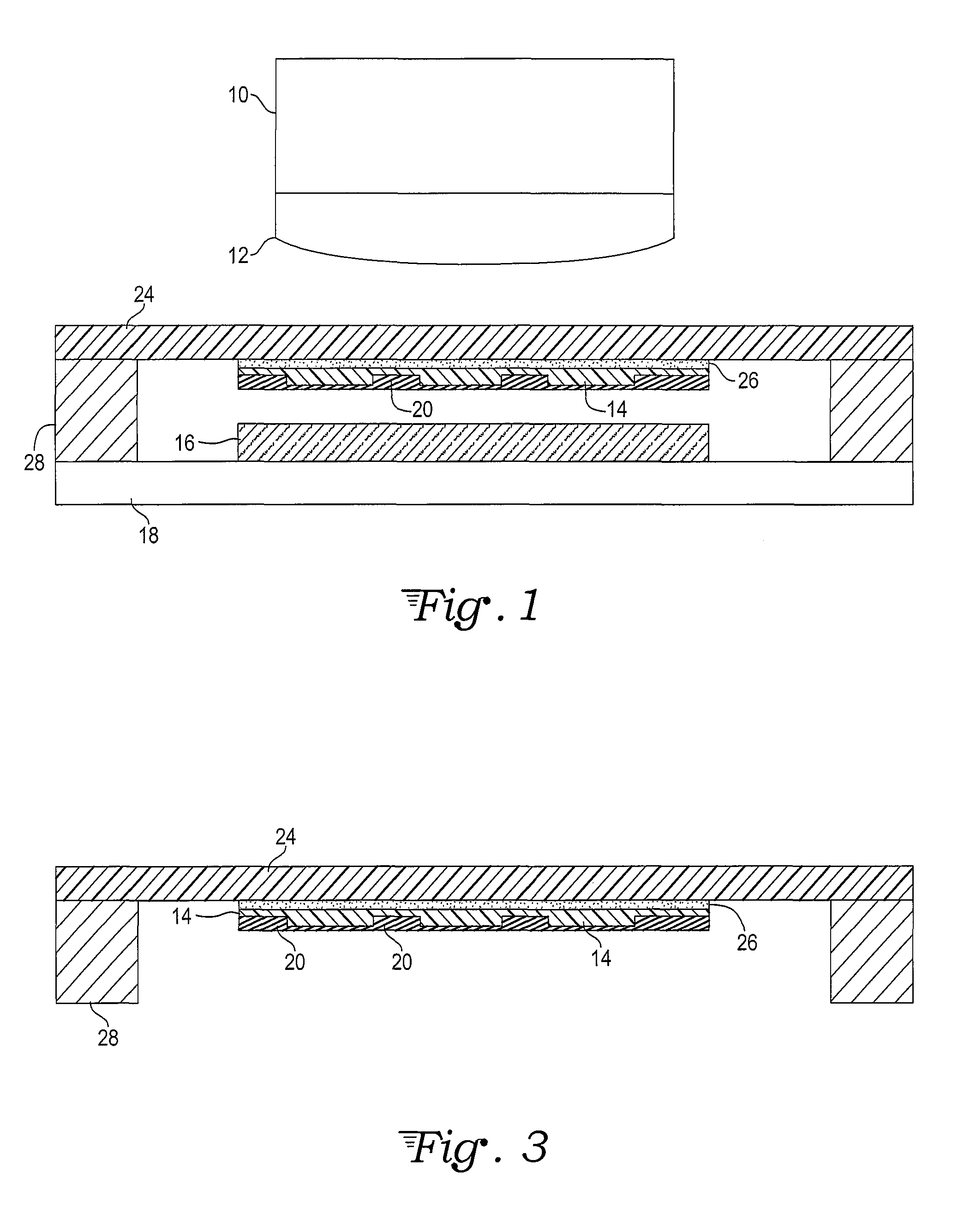

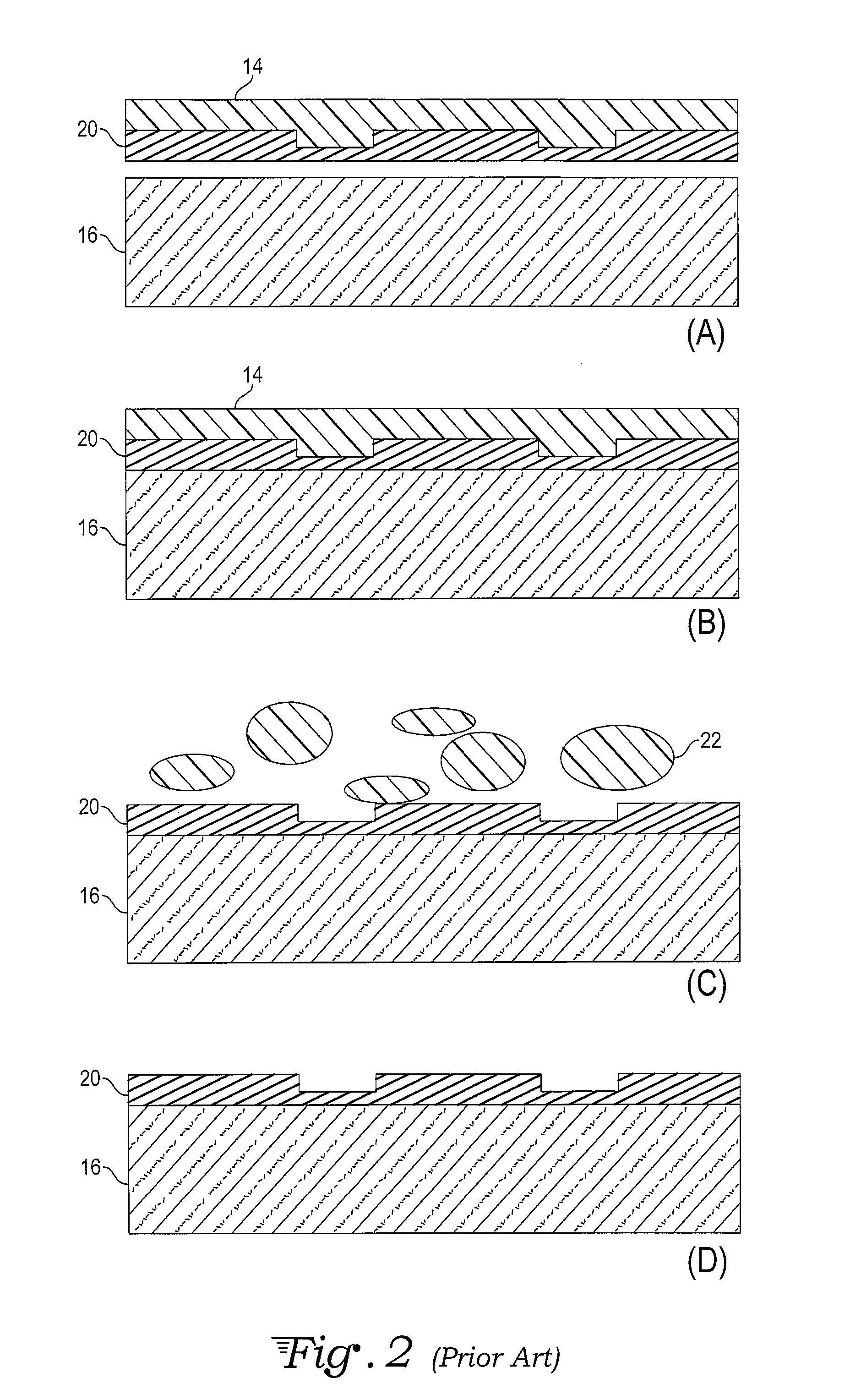

Molecular transfer lithography apparatus and method for transferring patterned materials to a substrate

InactiveUS20110058150A1Affect adhesionInhibition formationNanoinformaticsPhotomechanical apparatusWater bathsLithographic artist

A system and method to implement a molecular transfer lithography process is described. A destroyable nanopatterned template coated with functional material is attached to a removable carrier that is held suspended over a substrate, and a shaped pressure pad brings the functional material into contact with the substrate, initiating adhesion of the functional material to the surface of the substrate, and then detracting the pressure pad from the substrate. The substrate with destroyable template and removable carrier is then sent for further processing. In a preferred embodiment, the system and method are used to process a patterned polyvinyl alcohol template coated with a functional material that is thermal adhered to a substrate and after pressing, subjected to a water bath to dissolve away the template and carrier, leaving the functional material patterned on the substrate.

Owner:TRANSFER DEVICES

Semiconductor device and manufacturing method thereof

InactiveUS7713800B2Improve adhesionImprove reliabilityDischarge tube luminescnet screensNanoinformaticsIndiumManganese

Owner:SEMICON ENERGY LAB CO LTD

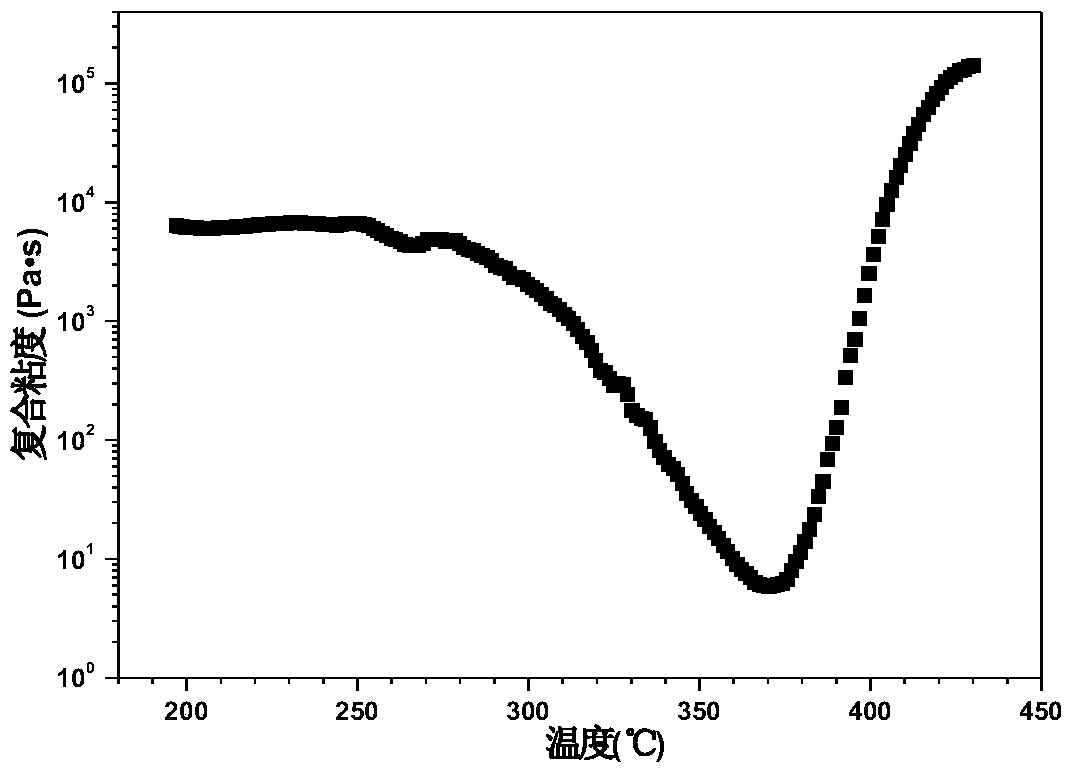

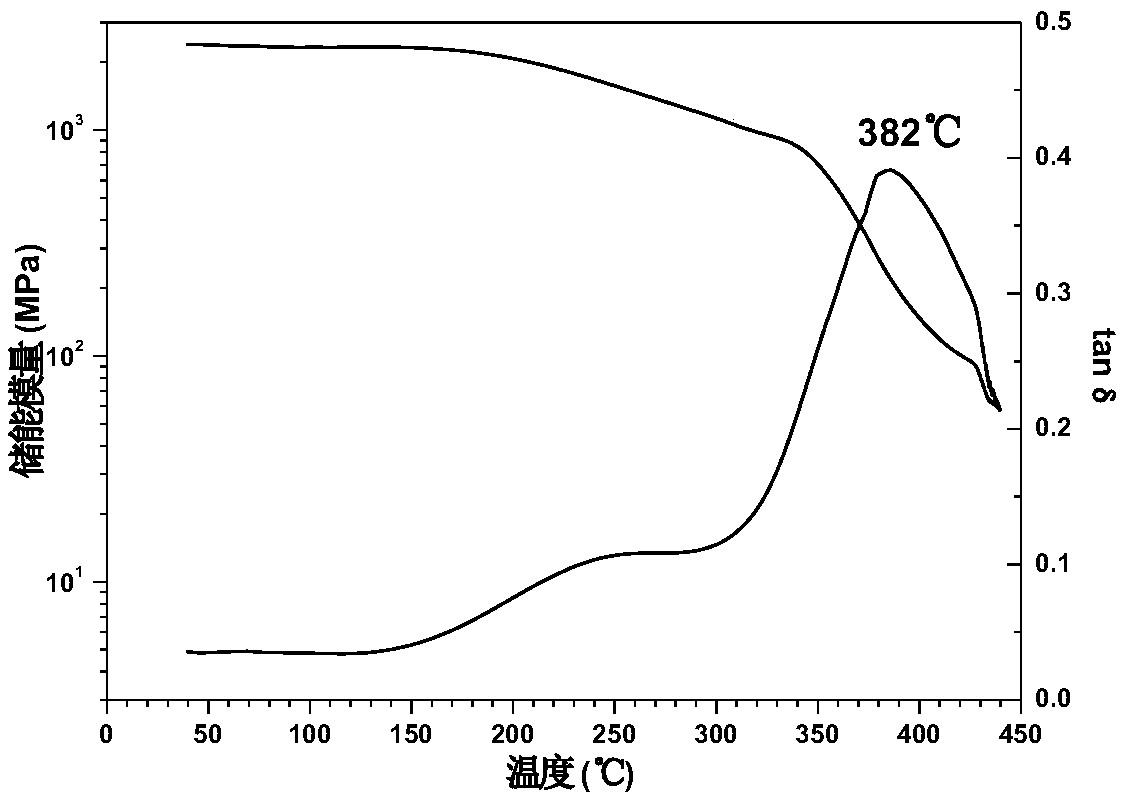

Polyimide adhesive and preparation method thereof

The invention relates to a polyimide adhesive and a preparation method thereof and belongs to the technical field of adhesives. The polyimide adhesive solves the problem that the polyimide adhesive ata temperature of greater than 350 DEG C has poor thermal instability and low adhesive properties. The polyimide adhesive is prepared from a polyimide adhesive prepolymer through curing. The preparation raw materials of the polyimide adhesive prepolymer comprise aromatic diamine containing a biphenyl structure, aromatic diamine containing a siloxane structure, aromatic dianhydride and a blocking agent. The preparation method comprises dissolving the polyimide adhesive prepolymer in an organic solvent to obtain a homogeneous solution, coating the surface of the adherend with the homogeneous solution, removing the organic solvent, carrying out curing to obtain the polyimide adhesive and bonding the adherend The polyimide adhesive can be used for the bonding of high temperature resistant parts in the fields of aviation, aerospace, precision machinery and petrochemical industry.

Owner:INST OF CHEM CHINESE ACAD OF SCI +1

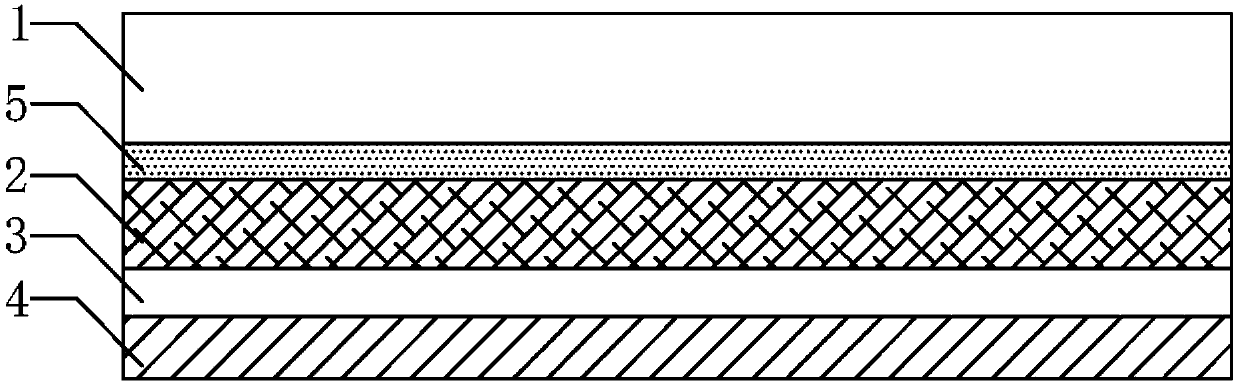

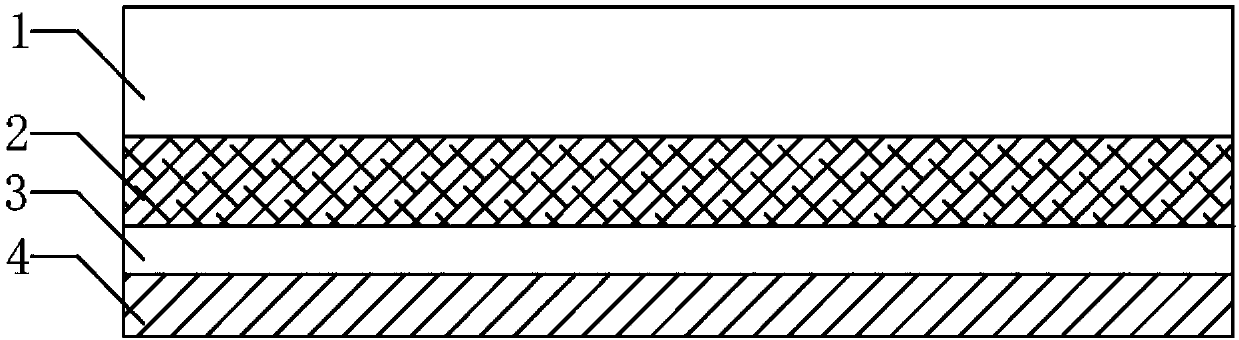

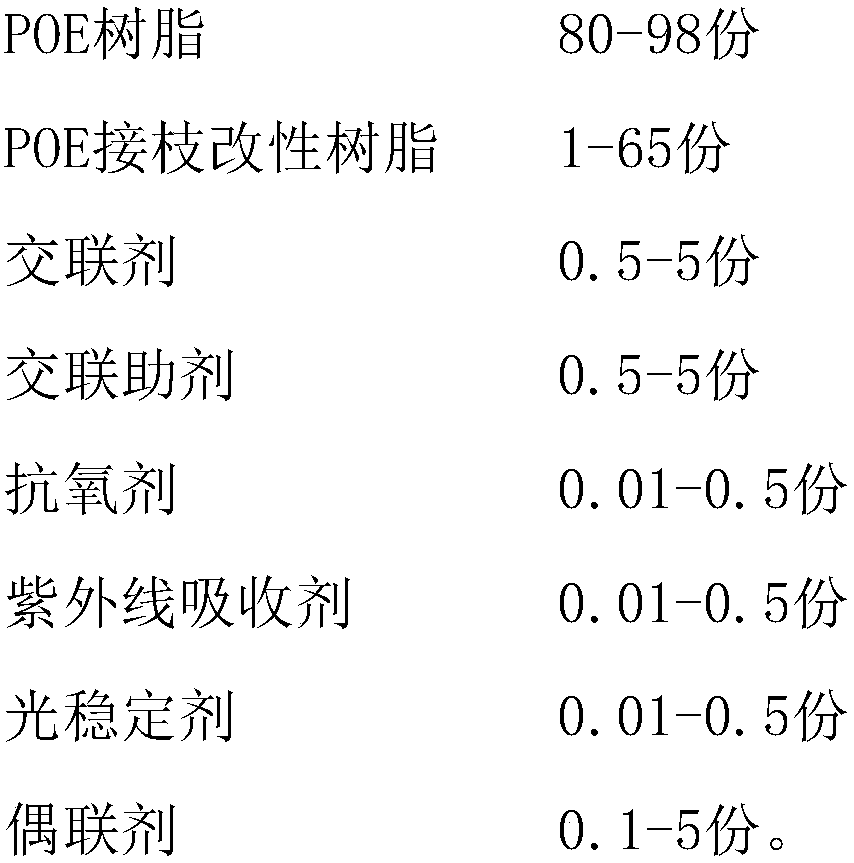

Adhesive film back plate integrated material and preparation process thereof

InactiveCN108034377AGood weather resistanceHigh light transmittanceNon-macromolecular adhesive additivesFilm/foil adhesivesElastomerThermoplastic

The invention relates to the technical field of adhesive film back plates, in particular to an adhesive film back plate integrated material and a preparation process thereof. The adhesive film back plate integrated material comprises an adhesive film layer, a structure reinforcement layer, a bonding layer and a weather-proof layer which are sequentially connected from inside to outside, a frostedlayer is arranged between the adhesive film layer and the structure reinforcement layer, and the adhesive film layer is prepared from modified thermoplastic POE (polyolefin elastomer). The adhesive film back plate integrated material has performances such as better barrier property, heat resistance, aging resistance, toughness, light transmittance and electrical insulating property, and is strongin layer-to-layer bonding power, not easy to fall off and long in service life. The preparation process is convenient to operate and control, high in production efficiency and low in production cost,the POE adhesive film layer and the frosted layer can be firmly adhered and smoothly curled, the thicknesses of the POE adhesive film layer and the frosted layer can be controlled, the prepared adhesive film back plate integrated material is excellent in performance, the assembly procedure of a component is simplified, and the assembly cost of the component is reduced.

Owner:MING CROWN ADVANCED MATERIAL CO LTD

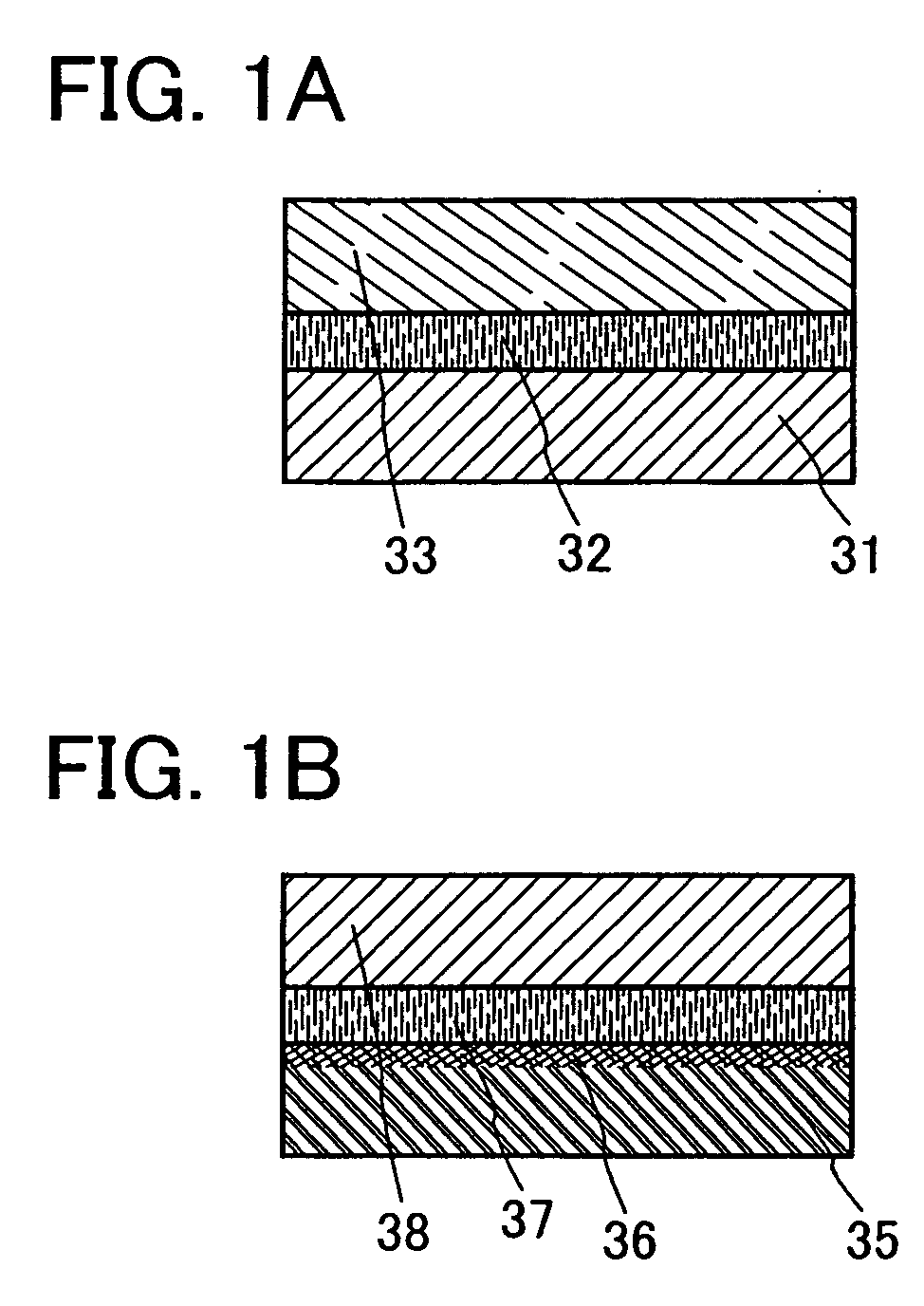

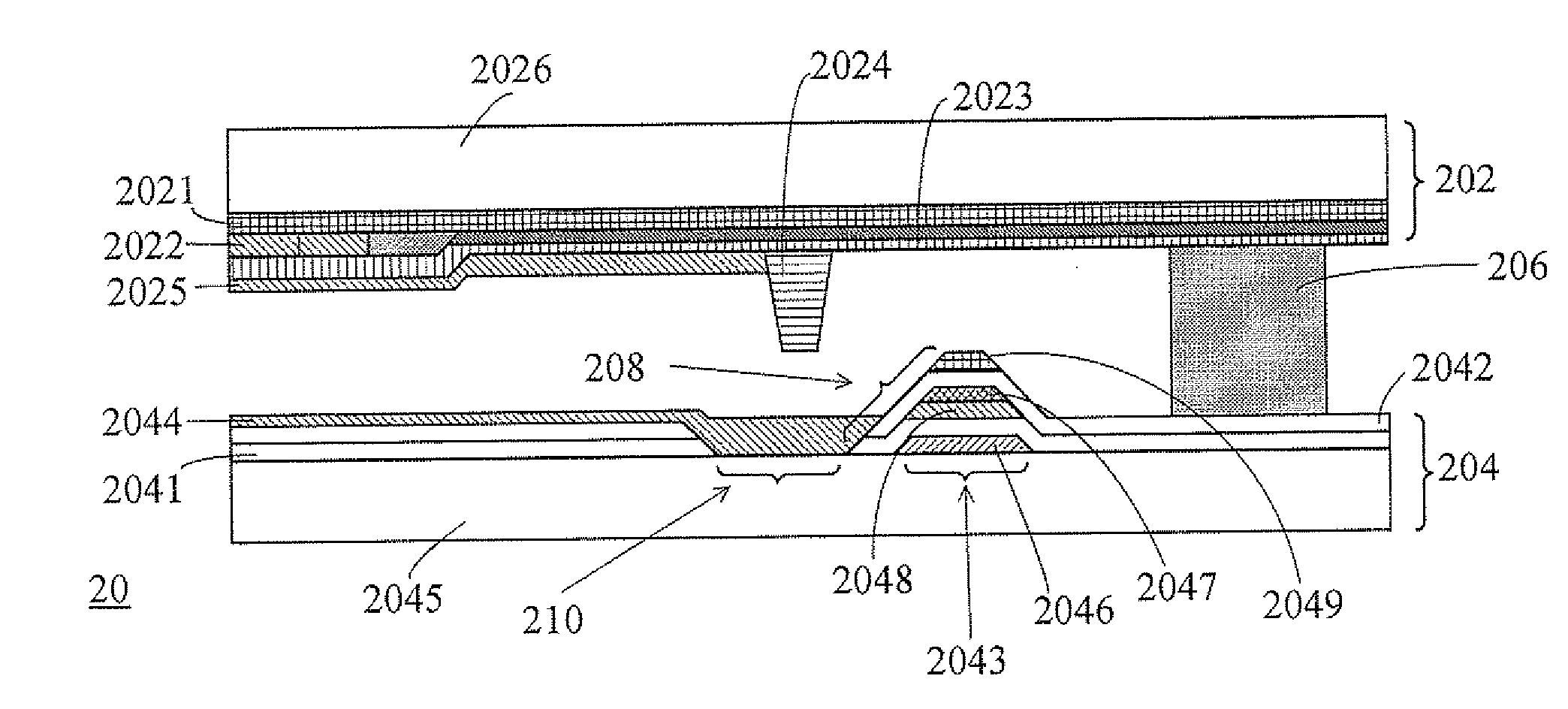

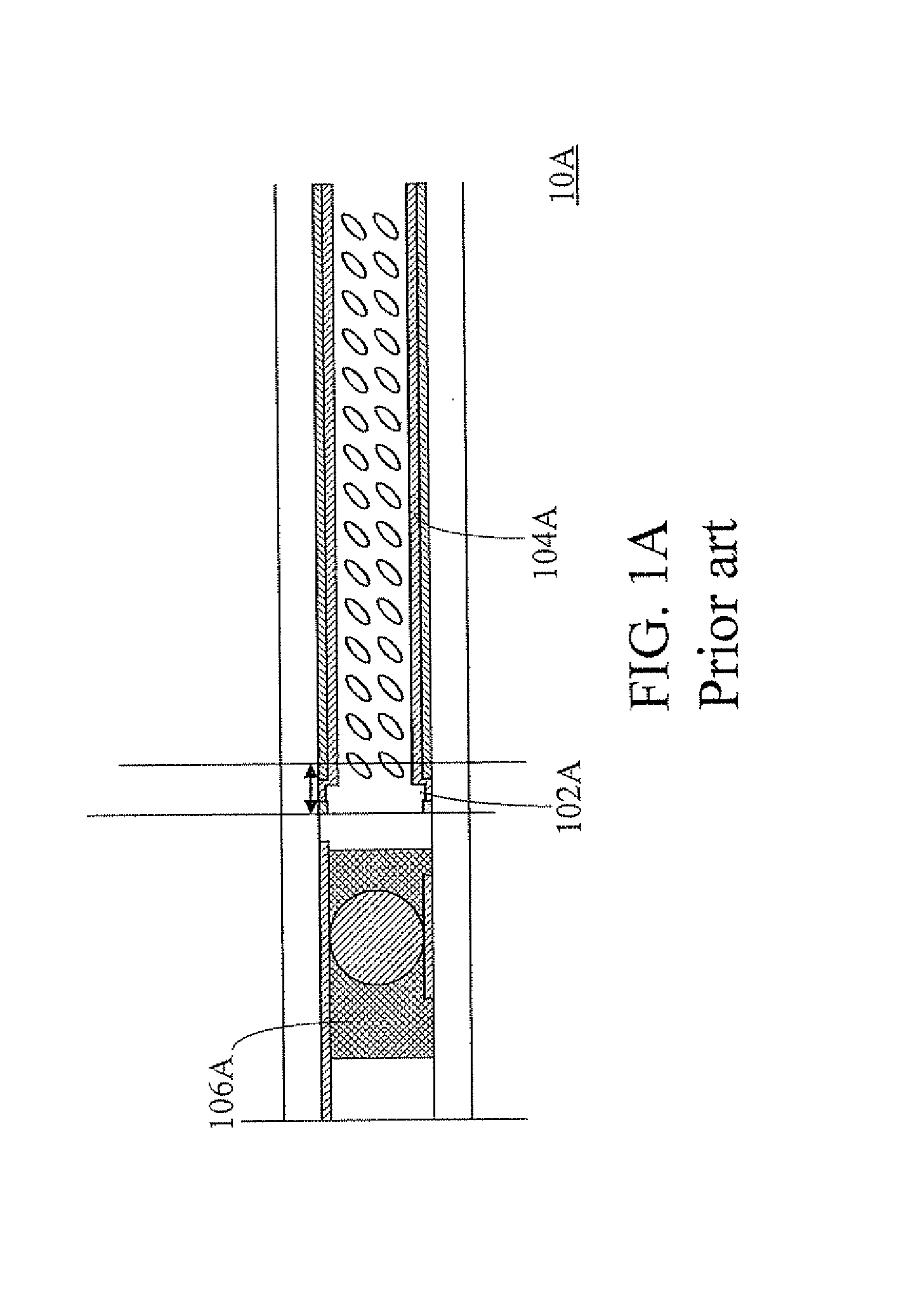

Liquid crystal panel and manufacturing method thereof

InactiveUS20150168752A1Affect adhesionInhibited DiffusionNon-linear opticsCold cathode manufactureEngineeringSealant

A liquid crystal panel is provided herein and comprises a top substrate, a bottom substrate and at least one sealant. The bottom substrate comprises a display region, a non-display region, a first limiting component and a second limiting component. The non-display region is adjacent to the display region. The first limiting component is formed as a convex at an edge of the non-display region. The second limiting component is formed as a concave between the first limiting component and the non-display region. When an alignment film is coated on the bottom substrate, the alignment film will not be spread to the non-display region by a conjunction of the first limiting component and the second limiting component.

Owner:SHENZHEN CHINA STAR OPTOELECTRONICS TECH CO LTD

Process for plasma coating a polypropylene object

InactiveUS20100227119A1Improve barrier propertiesOxygen permeability is inferiorLiquid surface applicatorsLayered productsPolyolefinPolymer science

A process for improving the barrier performance of a plasma coated object comprising a polyolefin is disclosed. The process involves ensuring that the surface of the object to be coated is smooth as characterized by having a root-mean-square surface roughness that varies by less than the thickness of the coating to be applied, typically less than 100 nm. The invention also relates to a process for improving the stain resistance of polyolefin based articles comprising plasma polymerizing an organosilicon compound under conditions to deposit a polyorganosiloxane layer onto the article and / or (b) plasma polymerizing a organosilicon compound under conditions to deposit a silicon oxide layer directly on the article or onto a polyorganosiloxane layer prepared according to step (a).

Owner:BRASKEM AMERICA

Crack-resistant, flame retardant, halogen-free, cable assembly and coating composition

ActiveUS7964663B2Affect adhesionBonded firmlyLiquid surface applicatorsSpecial tyresAlpha-olefinMelting temperature

Halogen-free, flame-retardant, crack-resistant, cable coatings are prepared from a composition comprising:A) 3 to 10 percent by weight of a low-melting temperature and medium to high grafted level maleic anhydride grafted polyethylene using a VLDPE base resin having density ranging from 0.86 to 0.91 g / cm3 and made with a single-site catalyst;B) 15 to 25% by weight of at least one EEA or EVA;C) 5 to 20% by weight of an α-olefin polymer; andD) 40 to 65% by weight of a flame retardant inorganic filler.

Owner:UNION CARBIDE CORP

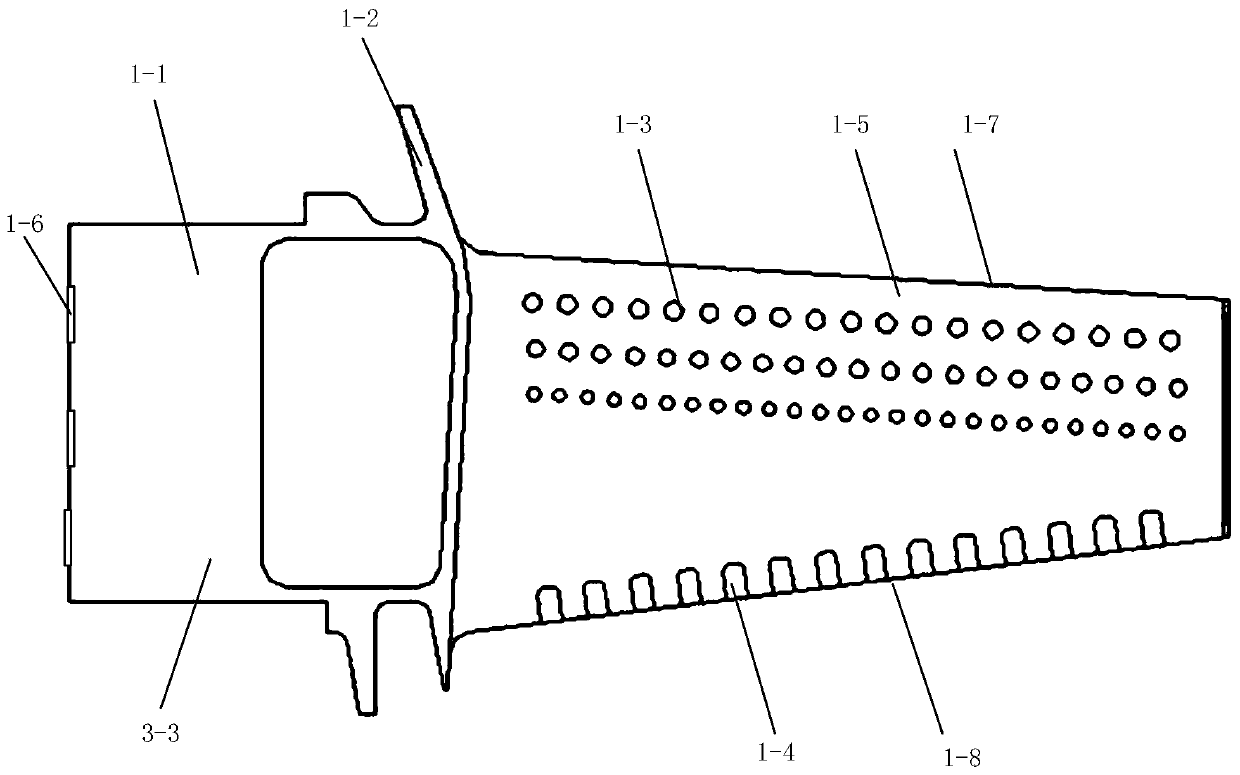

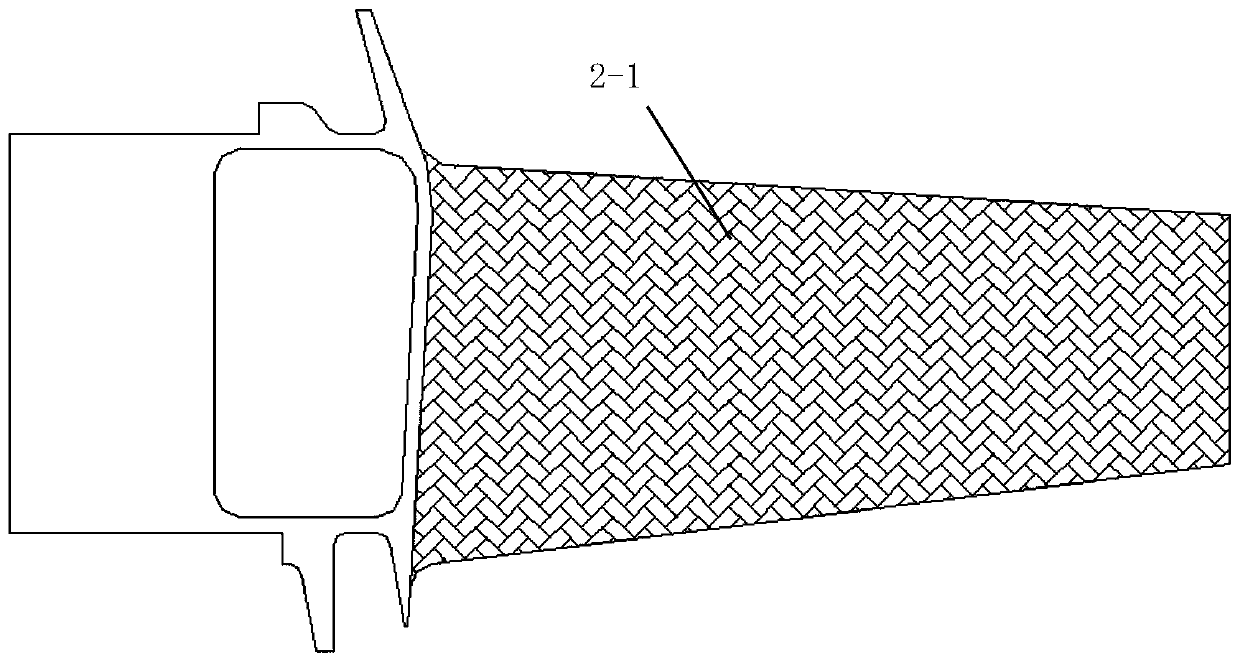

Method for protecting air film hole and tail split joint hole of blade

ActiveCN110439627AEffective protectionPrevent outflowBlade accessoriesMachines/enginesTurbine bladeEngineering

The invention discloses a method for protecting a gas film hole and a tail split joint hole of a blade. According to the method, a pressure-sensitive adhesive tape is wound on the surface of the bladebody, so that liquid paraffin enters a cavity inside a turbine blade from an air inlet, because the cavity is communicated with the gas film hole and the tail split joint hole, paraffin can enter thegas film hole and the tail split joint hole, and meanwhile, the pressure-sensitive adhesive tape prevents liquid paraffin from flowing out. When the blade is taken out and cooled, liquid paraffin issolidified in the cavity, the gas film hole and the tail split joint hole, so that the alloy matrix inside the blade will not be damaged during the chemical erosion process of the blade by acid solution. The method is simple to operate and convenient and quick to detect and repair the protective effect. There is no need to take special protective operations and requirements for different types ofgas film holes, and the gas film holes with different sizes and shapes can be effectively protected. The raw paraffin wax used in the method can be recycled, pollution is avoided, the environment is friendly, and an anti-pollution technology is not needed.

Owner:AECC AVIATION POWER CO LTD

Anti-corrosion glass silver mirror and production process thereof

The invention relates to the technical field of mirrors, and particularly discloses an anti-corrosion glass silver mirror and a production process thereof. The process comprises the following steps: polishing and cleaning the surface of glass; carrying out sensitization for the first time; plating palladium; then carrying out pretreatment; carrying out sensitization for the second time; performingsilver plating for the first time; performing silver plating for the second time; carrying out first passivation; carrying out secondary passivation; preheating; spraying paint for the first time; baking for the first time; spraying paint for the second time; carrying out secondary baking; cooling the surface of the glass to room temperature; cleaning the cooled surface of the glass; and air-drying the surface of the glass after cleaning. According to the production process, the binding power between a silver coating and the glass can be improved, so that the occurrence of edge corrosion is reduced, and the service lifetime of the glass silver mirror is prolonged.

Owner:苗东保

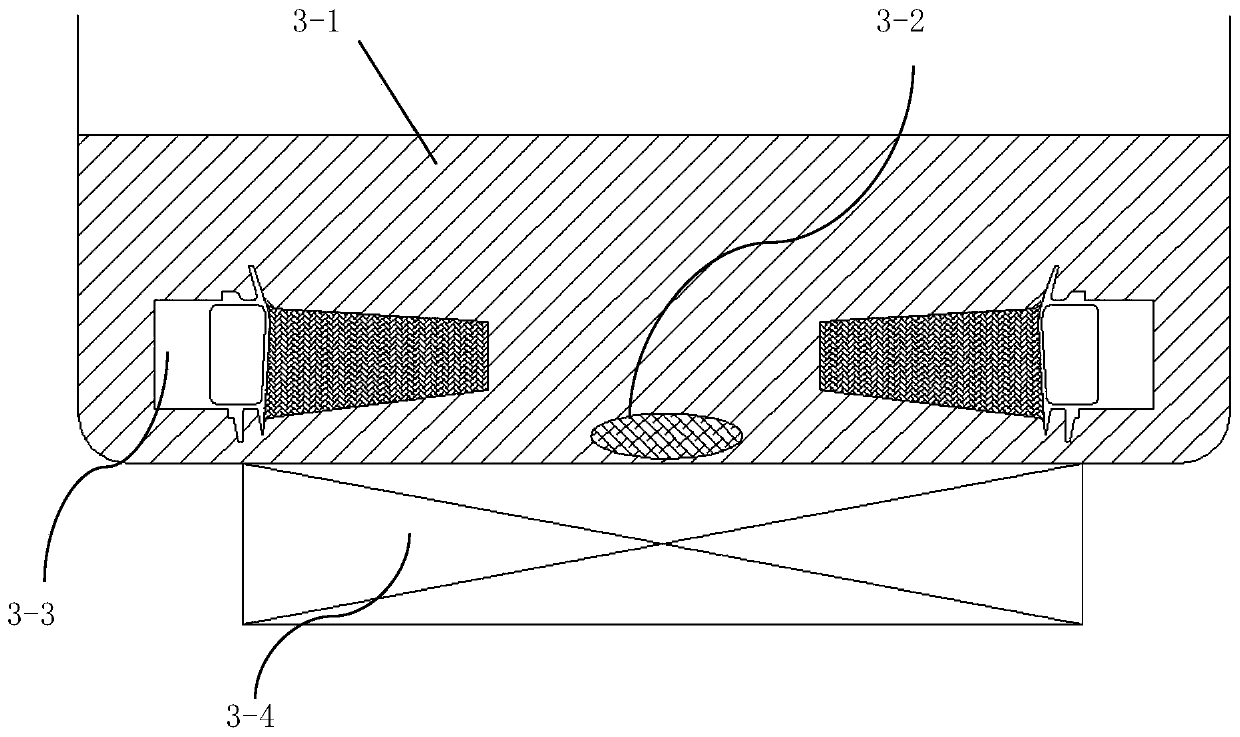

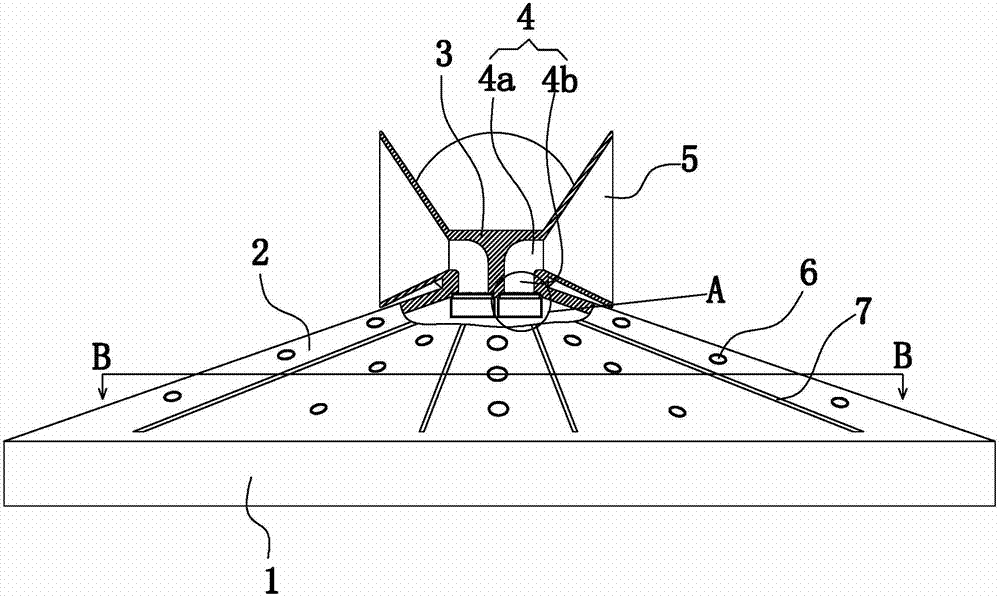

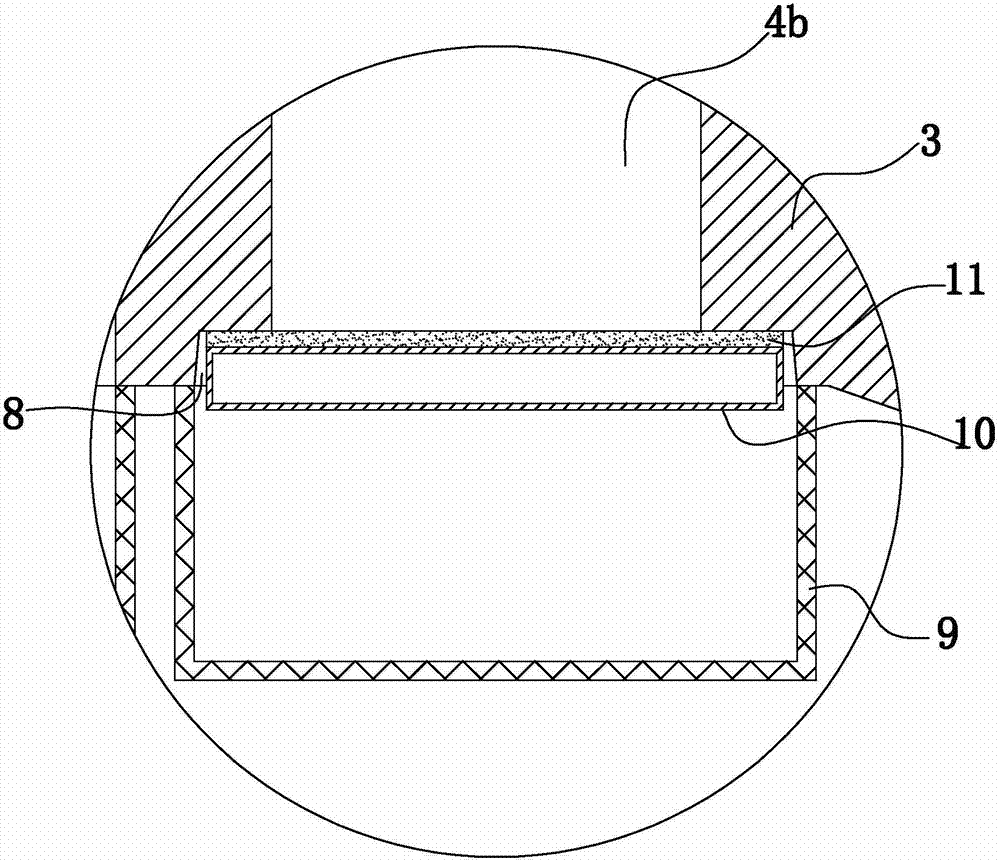

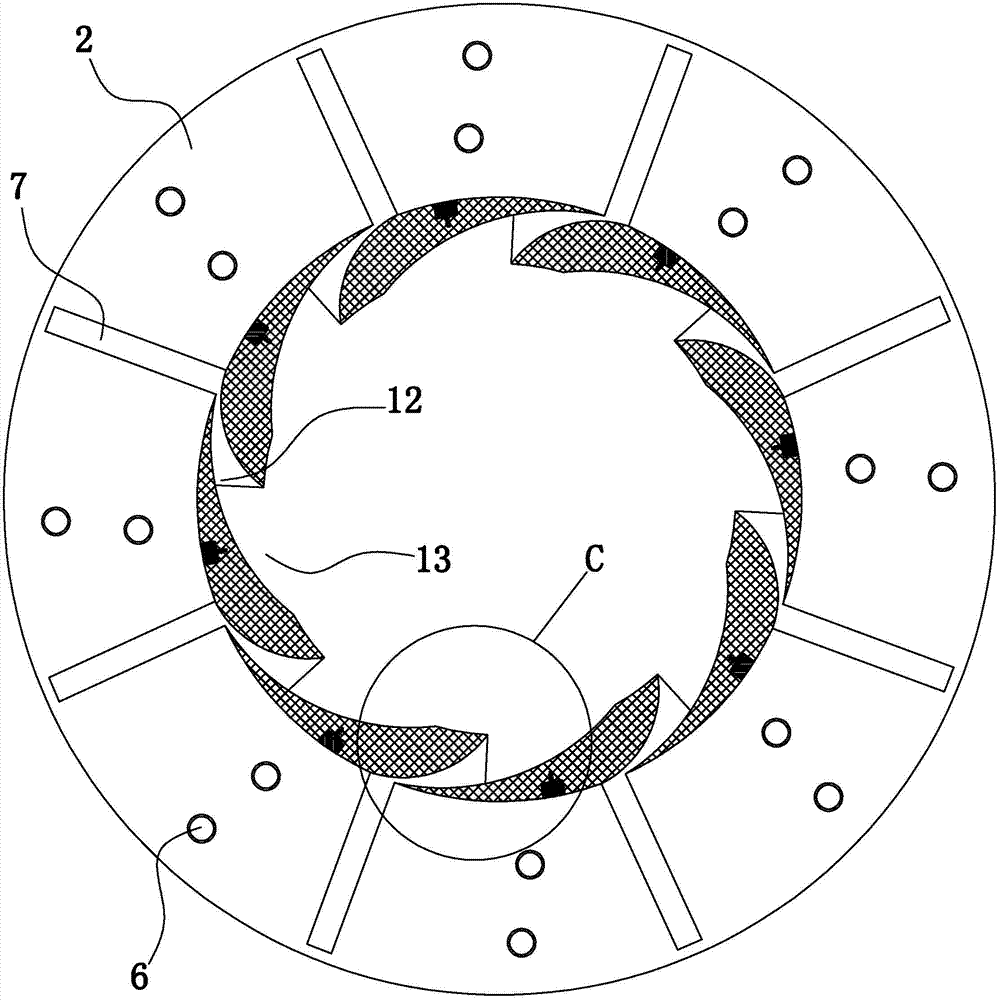

Algal reef with sediment self-cleaning function

InactiveCN103704120AAvoid influenceAffect adhesionClimate change adaptationPisciculture and aquariaGravity centerBiology

The invention discloses an algal reef with a sediment self-cleaning function and aims to provide an algal reef having the functions of clearing surface sediment by ocean current and preventing the sediment from affecting algal attachment and growth. The algal reef comprises a base and a hollow reef body arranged above the base. The center-of-gravity of the algal reef is located on the base or in the lower portion of the hollow algal reef body close to the base; the top of the hollow algal reef body is provided with a flow guide member; a plurality of ocean current guide-in passages communicated with an inner cavity of the hollow algal reef body are evenly and peripherally arranged in the side of the flow guide member; inner ports of the ocean current guide-in passages face down; the edge of the inner port of each ocean current guide-in passage is provided with a dented circular step; a guide mesh cover is arranged below each circular step; a floating cover plate for covering the inner port of the corresponding ocean current guide-in passage is arranged in each circular step; the sidewall of the hollow algal reef body is provided with a plurality of arc guide passages, and the arc guide passages form scour slits in the outer side of the hollow algal reef body.

Owner:MARINE FISHERIES RES INST OF ZHEJIANG

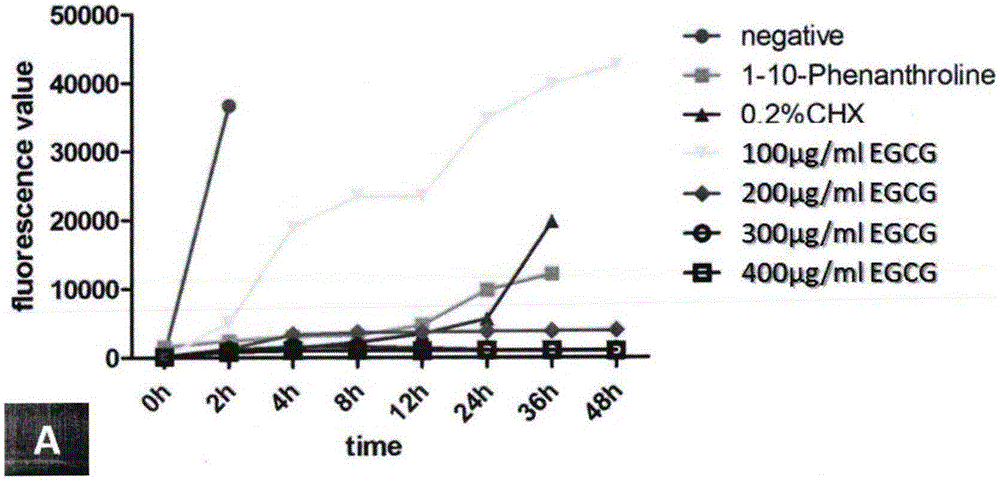

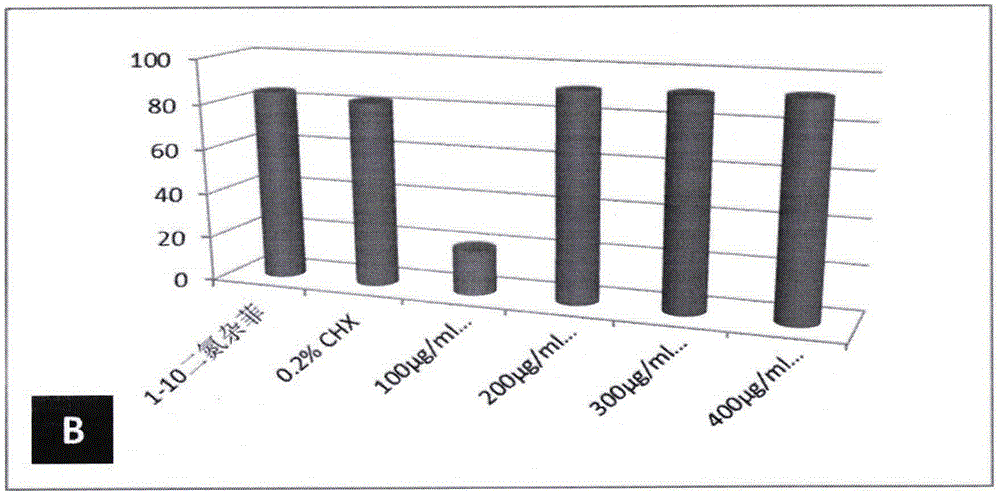

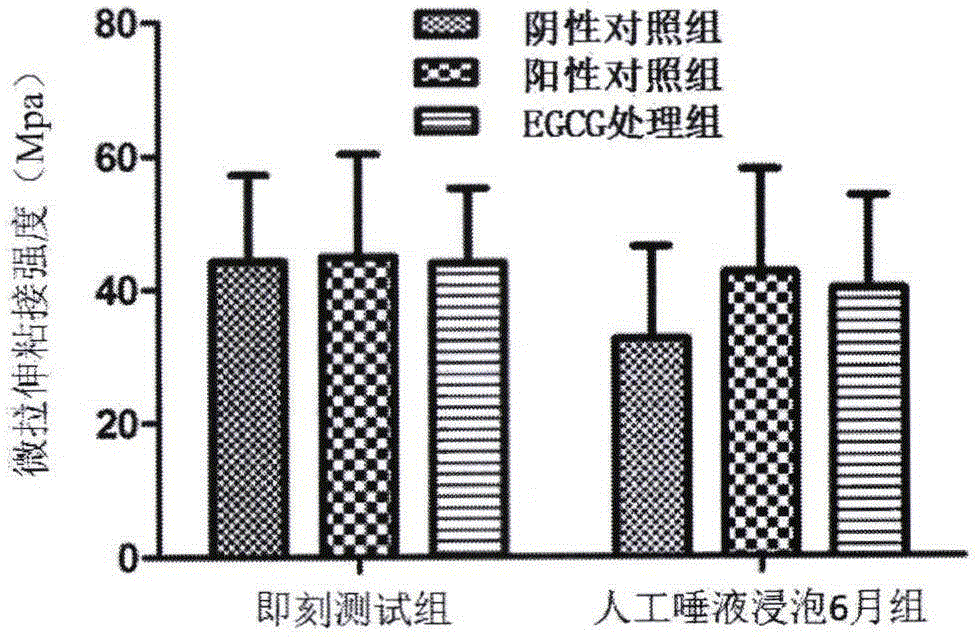

Application of epigallocatechingallate (EGCG) in improving dental resin adhesive material restoration performance

InactiveCN105342863AImprove long-term restorationHighly inhibitoryImpression capsDentistry preparationsPre treatmentDentin

The invention discloses application of epigallocatechingallate (EGCG) in improving dental resin adhesive material restoration performance. The application of the EGCG prepared into a 400 micrograms / ml ECCG ethanol solution used as a pretreating agent in the coronal dentin adhering aspect and the application of the EGCG prepared into the 400 micrograms / ml ECCG ethanol solution used as the pretreating agent in root canal dentin adhering aspect are involved. By means of the characteristic of the EGCG for restraining matrix metalloproteinase activity and inoxidizability, the EGCG is prepared into the pretreating agent to be applied to coronal dentin and root canal dentin adhering, and the long-term restoration effect of a clinic resin adhesive restoration body and the long-term restoration effect on devital teeth with deficiency of a large amount of tooth tissue are effectively improved.

Owner:FOURTH MILITARY MEDICAL UNIVERSITY

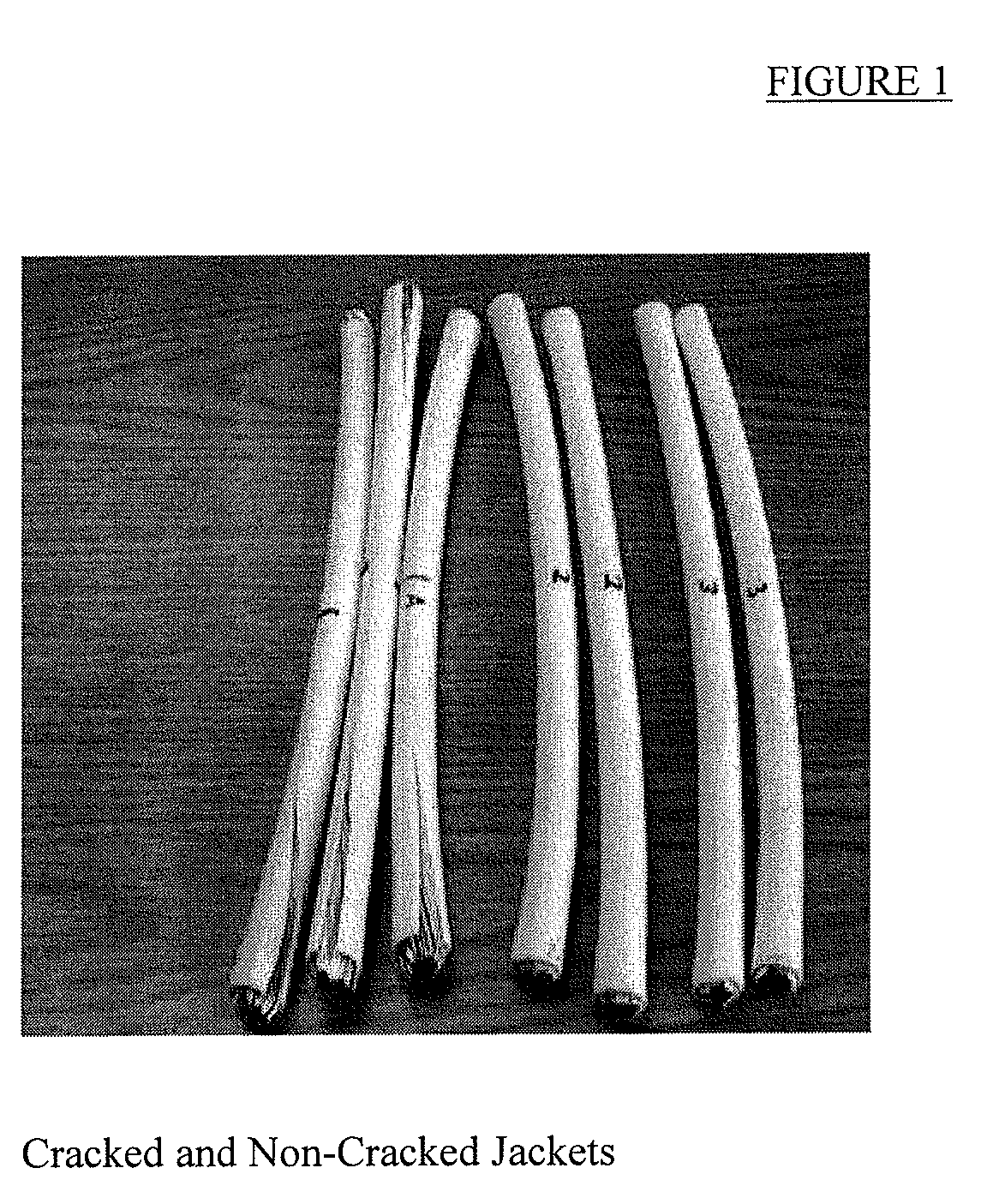

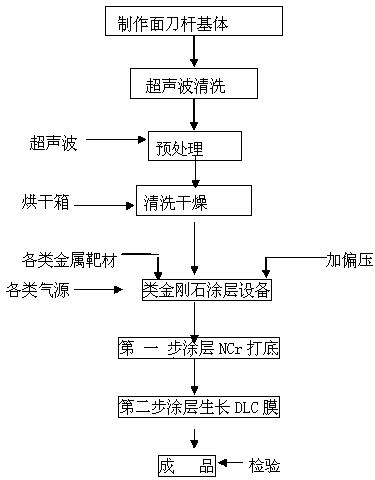

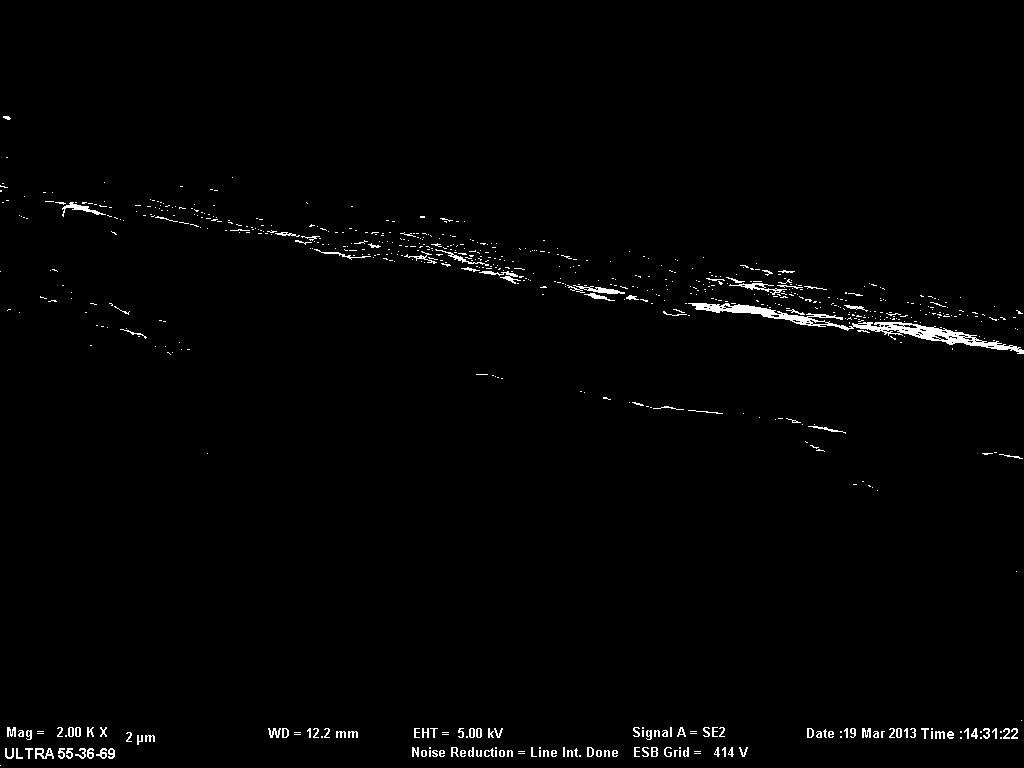

Preparation process of chromium oxynitride and diamond-like carbon film composite coating fine dried noodle knife roller

InactiveCN103741093AAffect adhesionPlay an etching roleVacuum evaporation coatingSputtering coatingCarbon filmAnti bacteria

The invention discloses a process of a chromium oxynitride and diamond-like carbon film (DLC) composite coating fine dried noodle knife roller or stick. The process comprises the following steps of cleaning, drying, performing pre-treatment, coating a NO2Cr film layer as a transition layer (an anchoring layer) and coating a DLC outer film layer. By utilizing the process disclosed by the invention to coat a diamond-like carbon film on the fine dried noodle knife roller or stick, the hardness, toughness, wear resistance, corrosion resistance, antibacterial performance and lubrication performance of a fine dried noodle knife bar can be improved, so that the service life can be prolonged by 8-10 times. The process disclosed by the invention can be widely applied to other food machines.

Owner:武汉世纪中航超强金刚石膜高科技有限公司

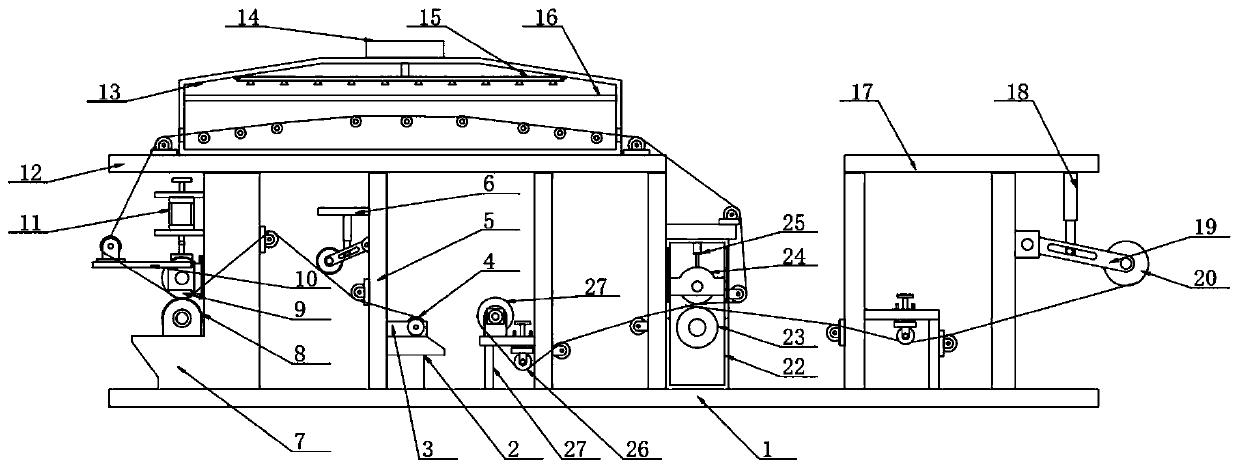

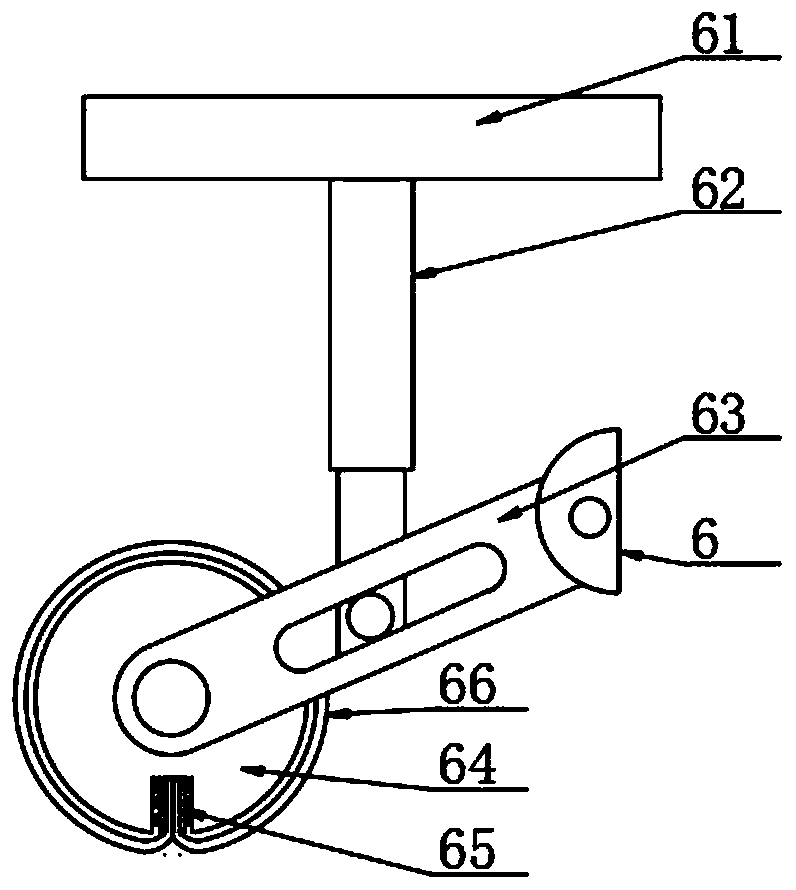

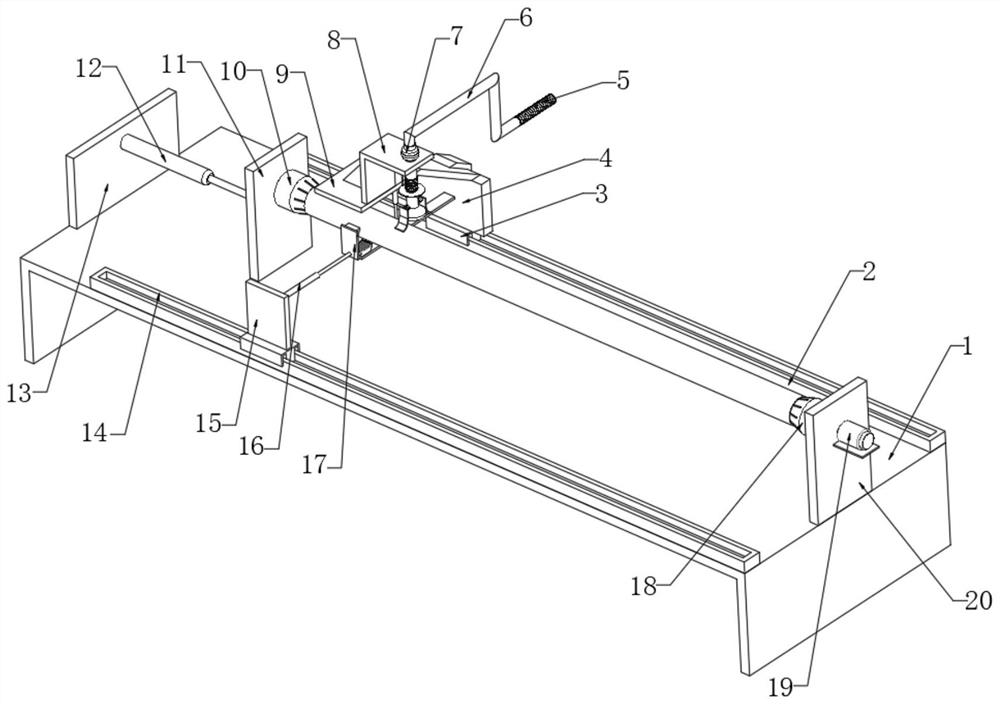

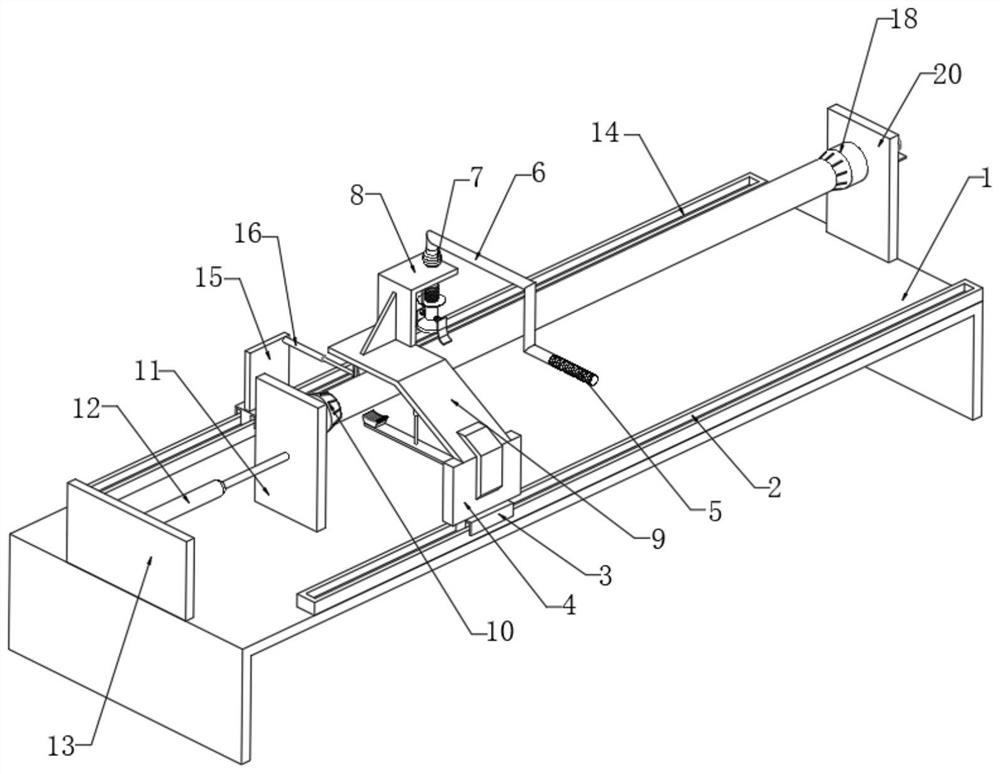

Gold stamping mechanism fixing device and method of gold stamping machine for processing of textiles

ActiveCN110370795AImprove stabilityImprove glue adhesionRotary pressesPrinting press partsPaper sheetEngineering

The invention discloses a gold stamping mechanism fixing device of a gold stamping machine for processing of textiles in the textile processing technology field. The gold stamping mechanism fixing device of the gold stamping machine for the processing of the textiles comprises a bottom seat, wherein a dust removal part is arranged on an upper position on the left side of a first group support frame, a glue spreading frame is fixedly arranged on the left side of the top of the bottom seat, a mounting cover is slidably arranged on an upper position in the inner cavity of a gluing box, a mirror surface roller is movably arranged in the mounting cover through a rotation shaft, and a winding roller is movable arranged on the left side of the top of an L-shaped frame on the left side through twogroups of roller seats. The gold stamping mechanism fixing device of the gold stamping machine for the processing of the textiles is provided with the dust removal part, can remove dust before preforming gold stamping on a film through the dust removal part, improves following gluing stability and glue adhesion force, improves following gluing force, and meanwhile uses a spring and a pressing plate for fixing dust removal paper, thereby conveniently replacing the dust removal paper, and meanwhile uses a gluing part, thereby achieving controllability for flow rate of glue, and not only can prevent the problems that the glue is excessively wasted, and the gluing force is influenced due to the amount of the glue is small, but also simultaneously guarantees uniformity of the glue smeared on the surface of the film.

Owner:苏州沙梦纺织品有限公司

Formula and preparation method of low-surface-energy long-acting anti-fouling paint

InactiveCN105670503AExtended shelf lifeImprove performanceAntifouling/underwater paintsPaints with biocidesTO-18Organic solvent

The invention discloses a formula and preparation method of low-surface-energy long-acting anti-fouling paint. The formula contains the ingredients in percentage by mass: 18.0% to 22.0% of polysiloxane resin polymer, 12% to 18% of polytrifluorochloroethylene resin polymer, 26.0% to 32.0% of organic solvent, 18% to 32% of pigment / filler, 3% to 5% of dispersant, 0.8% to 2.6% of thickener, 0.1% to 0.2% of antifoamer and 0.1% to 0.2% of leveling agent. The prepared paint is used for protecting ocean shipping ships and can achieve a long-acting anti-fouling effect.

Owner:COSCO KANSAI PAINT & CHEM TIANJIN

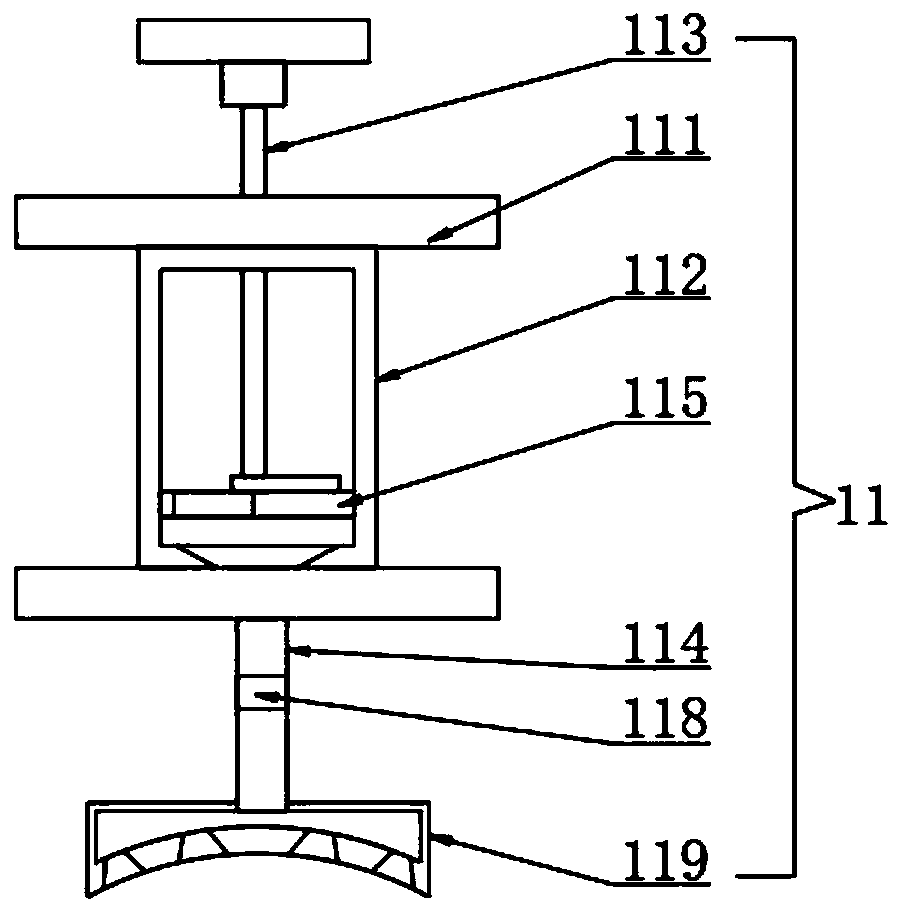

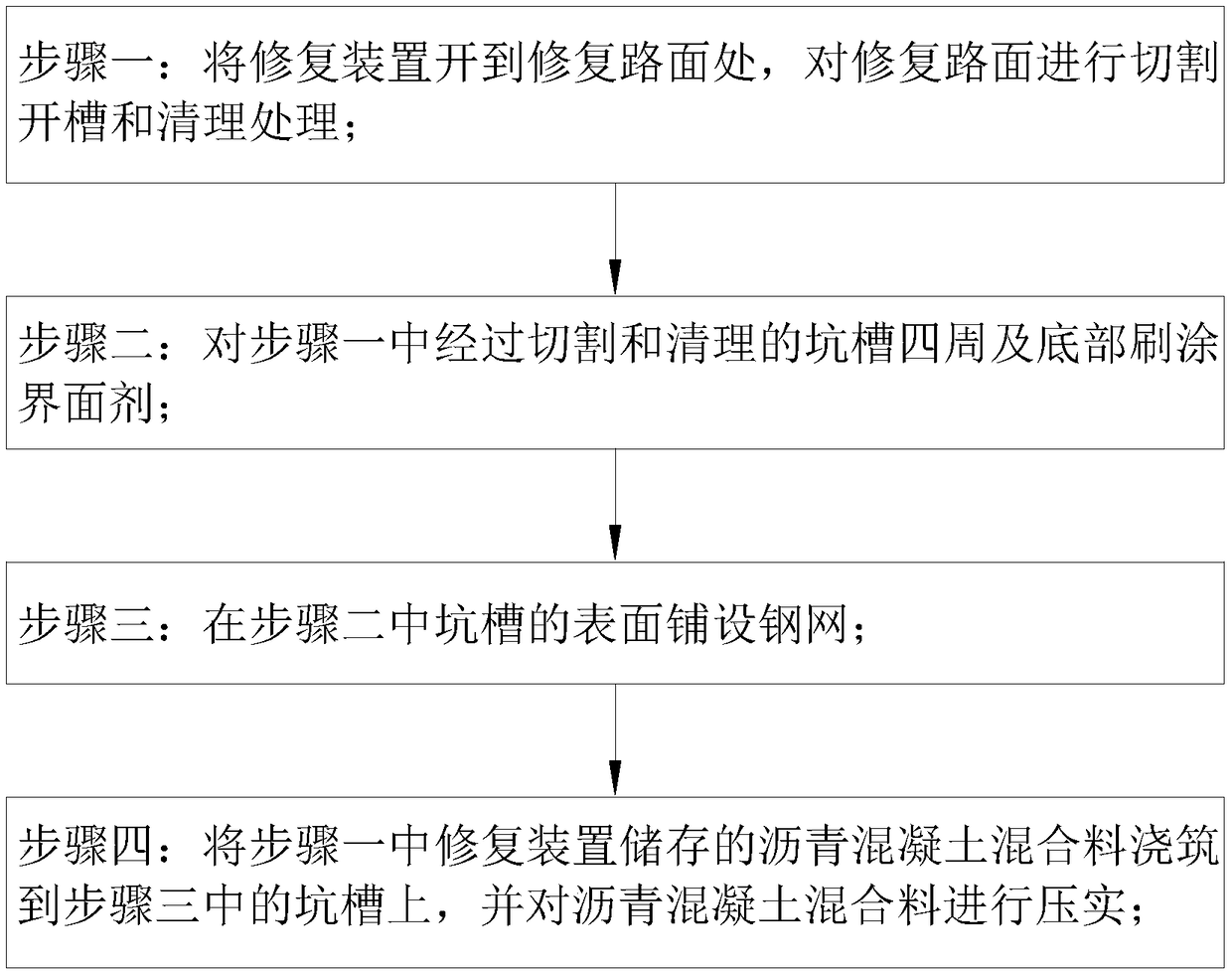

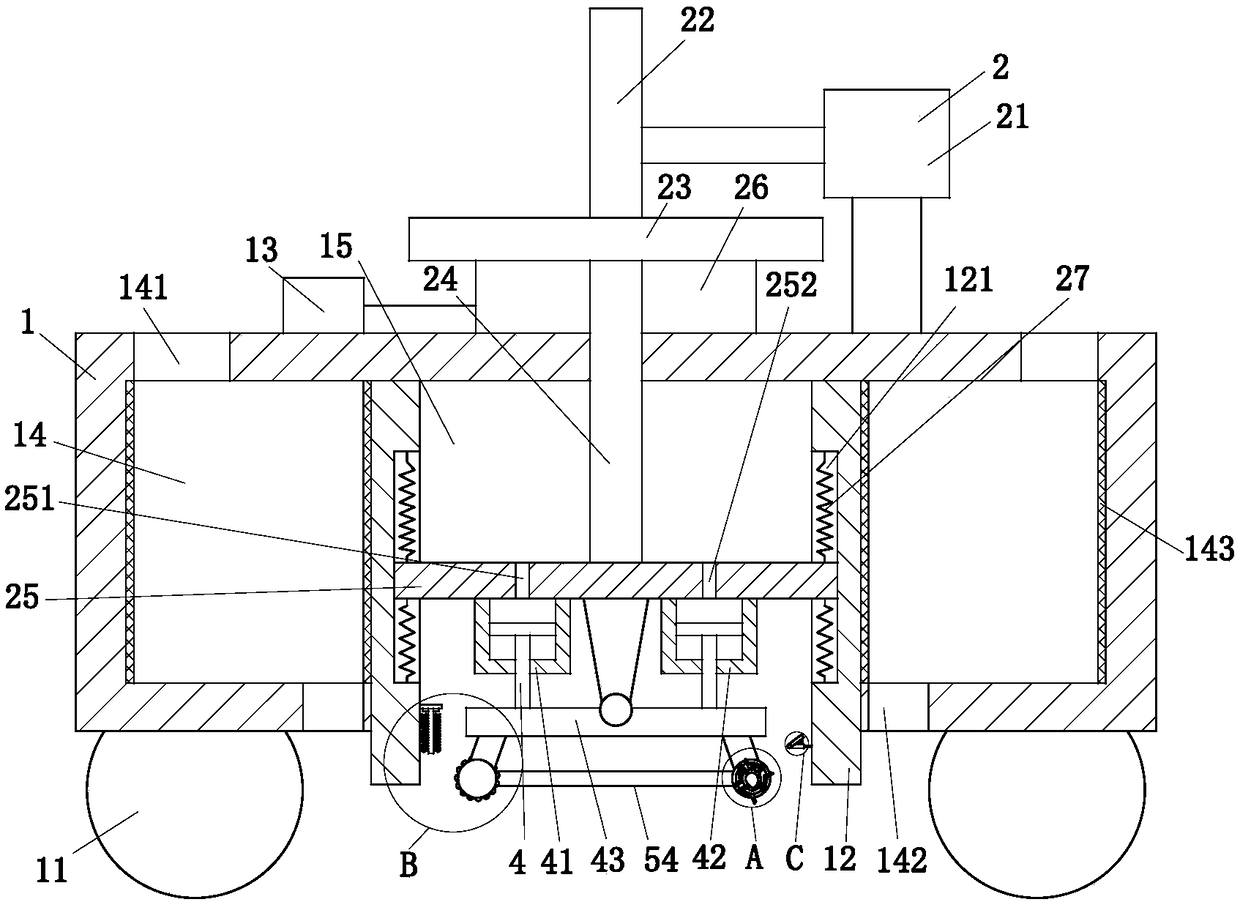

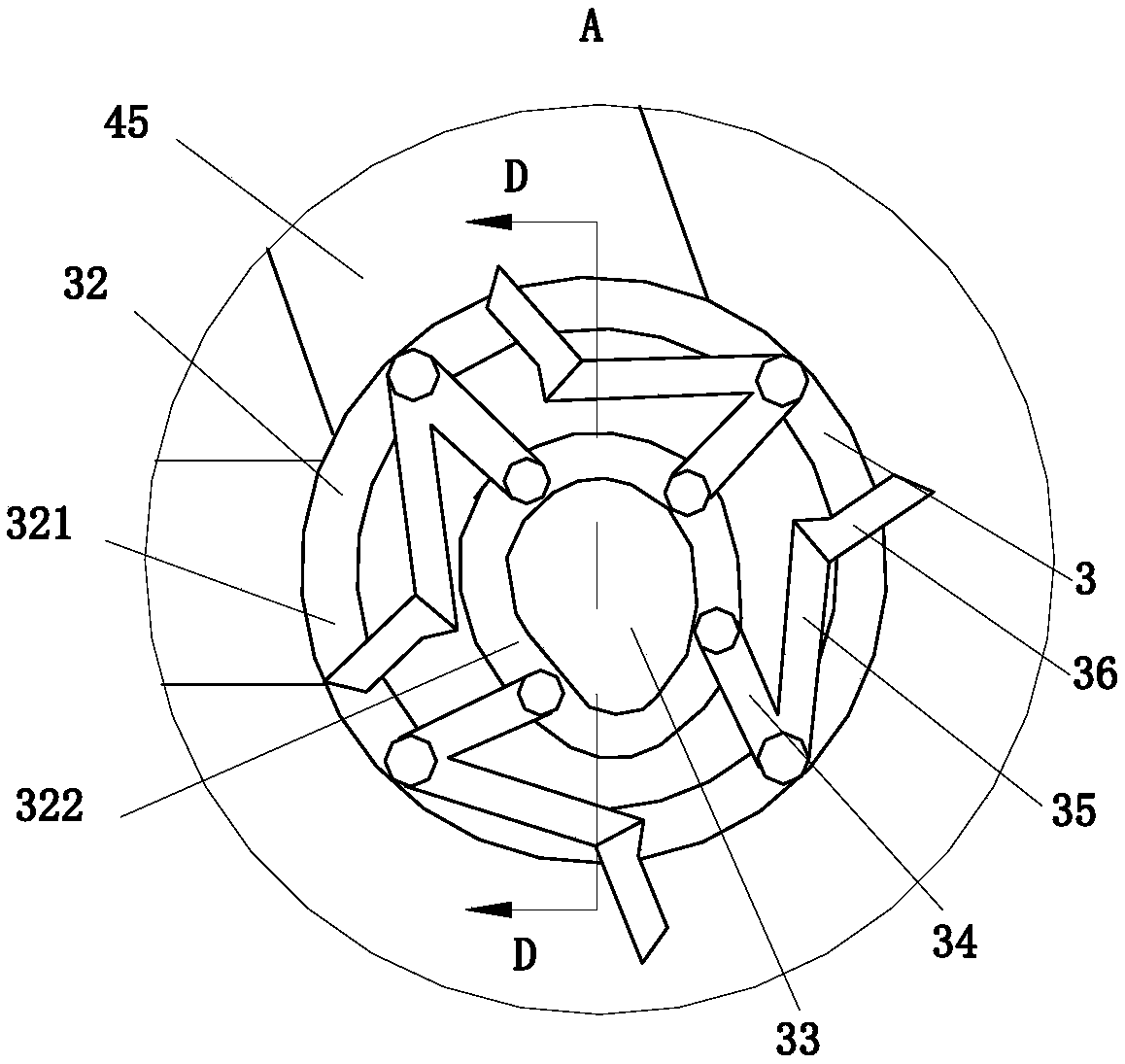

A method for repair damaged asphalt pavement

ActiveCN109082990AImprove securityExtended service lifeDispersed particle separationRoads maintainenceRoad surfaceEngineering

The invention belongs to the technical field of road construction, in particular to a method for repairing damaged asphalt pavement. The method adopts a repairing device which comprises a locomotive and a rolling wheel. The utility model also comprises a No. 1 plate, a driving unit, a cutting unit, a control unit and a No. 1 cleaning unit. The rolling roller is used for tamping the asphalt concrete mixture; The cutting unit is used for slotting the damaged part of the pavement; The No. 1 cleaning unit cleans the slotted road surface. On the one hand, the asphalt concrete mixture is completelypoured into the repairing notch, and the pavement is leveled by the rolling roller, so that the driving safety of the vehicle is improved; on the other hand, the asphalt concrete mixture is completelypoured into the repairing notch by the mutual cooperation of the cutting unit, the cleaning unit No. On the other hand, the dust in the pavement cutting is cleaned out of the notch to increase the bonding force between the asphalt concrete mixture and the notch, thus prolonging the service life of the highway pavement.

Owner:江苏雨梦建设有限公司

Graphene heating slurry and preparation method thereof

InactiveCN110483966AImprove performanceAffect adhesionChemical industryHeat-exchange elementsSolventCarbon black

The invention relates to the technical field of heating slurry, provides a graphene heating slurry and a preparation method thereof which solve the problems of non-uniform heating and low heat efficiency due to the fact that the linear heating materials are used in the electric heating equipment in the prior art. The graphene heating slurry comprises the following raw materials in parts by weightof 30-50 parts of graphene, 5-10 parts of carbon black, 50-70 parts of synthetic resin, 10-16 parts of metal powder, 3-5 parts of an antistatic agent, 5-8 parts of a dispersing agent, 1-3 parts of a thickening agent, 150-300 parts of a solvent, 10-18 parts of a curing agent and 0.6-1.2 parts of a titanate coupling agent.

Owner:牛墨石墨烯应用科技有限公司

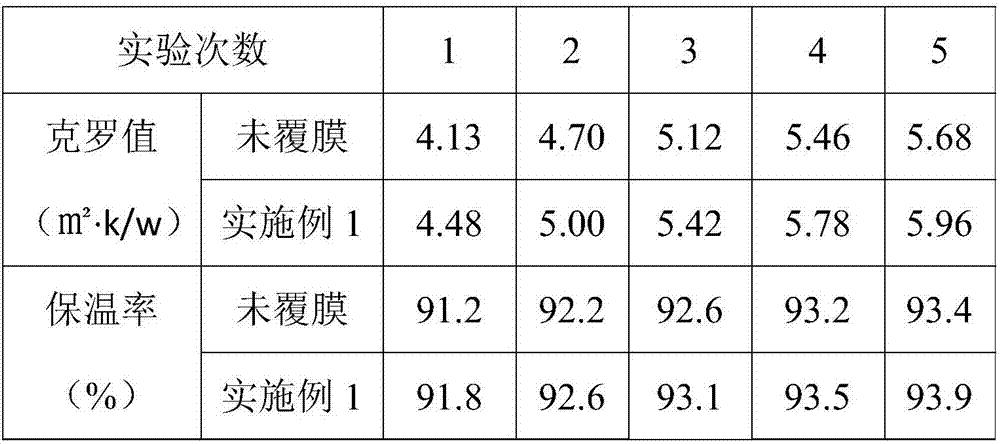

Down leak-proofing fabric and processing method thereof

InactiveCN107877952AImprove breathabilityGood skin affinitySynthetic resin layered productsFilling materialsCompound (substance)

The invention provides a down leak-proofing fabric and a processing method thereof. WS type hot melt adhesives are sprayed on a textile fabric to be laminated with a film-covering material, and hot-pressing treatment is performed to obtain the down leak-proofing fabric. Compared with the prior art, according to the down leak-proofing fabric, a film-covering functional fabric is prepared through ahot melt adhesive laminating process. A natural fiber fabric with good air permeability and good skin-friendly property is selected as the textile fabric, organization structures are not limited, a jacquard fabric can even be selected, and a thin film with high permeability is selected as the film-covering material. The surface of the thin film is in contact with down filling materials, and the human body is in contact with natural fiber fabric components. No chemicals are added to the contact surface of a natural fiber fabric in contact with the human body, which will not lead to phenomena such as sensitization and the like of susceptible population. Moreover, down products processed have high down leak-proofing performance, almost zero down leak of the down products is achieved, and thedown products have broad application prospects. The down leak-proofing fabric has good down leak-proofing performance and fastness and can be washed repeatedly, and the down leak-proofing performanceand wearing comfort performance are not reduced after washing 10 times.

Owner:ANHUI UNIVERSITY OF TECHNOLOGY AND SCIENCE

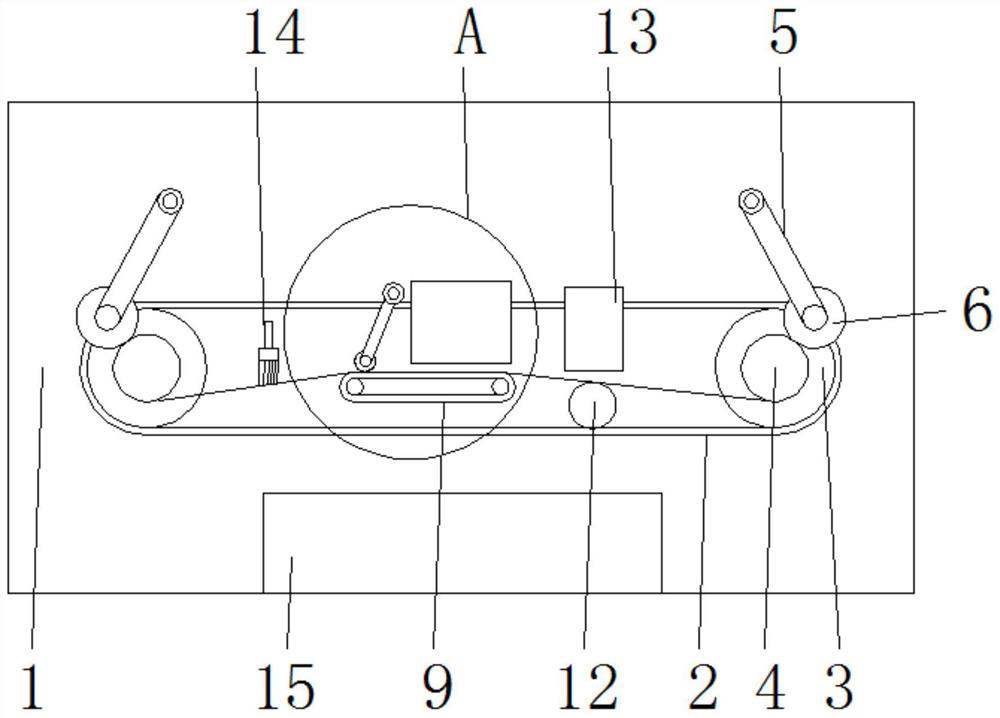

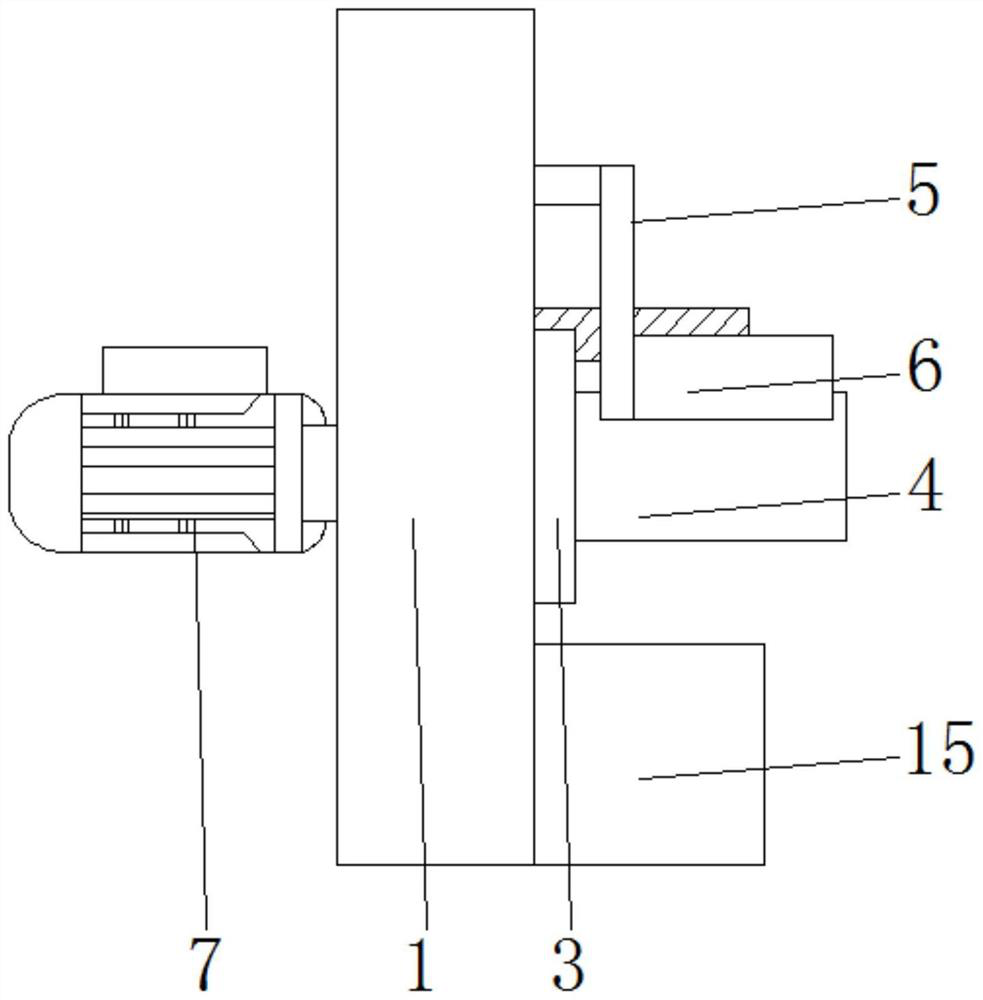

Non-woven fabric sizing equipment

InactiveCN112374265AImprove work efficiencyReduce pullingArticle deliveryElectric machineryStructural engineering

The invention belongs to the technical field of non-woven fabrics, and discloses non-woven fabric sizing equipment which comprises a machine body, wherein a connecting belt is arranged on one side ofthe machine body, two rotating discs are rotatably connected to the two sides inside the connecting belt, the two rotating discs are both rotatably connected to one side of the machine body, and rotating rods are fixedly connected to the sides, away from the machine body, of the two rotating discs; two long rods are rotatably connected to the positions, at one side of the two rotary discs, on themachine body, volute spiral springs are mounted between the two long rods and the machine body, extrusion rods are rotatably connected to the bottom ends of the sides, away from the machine body, of the two long rods, and the two extrusion rods make contact with the top ends of the two rotary rods correspondingly; a sizing device is mounted on the position, at one side of the rotary discs, on themachine body, a motor is fixedly connected into the machine body, the motor is rotatably connected to the rotary discs, a glue sprayer is arranged between the two rotary discs, and the glue sprayer isinstalled on the position, at one side of the rotary discs, on the machine body.

Owner:江门市新会区美力赛无纺布纤维制品有限公司

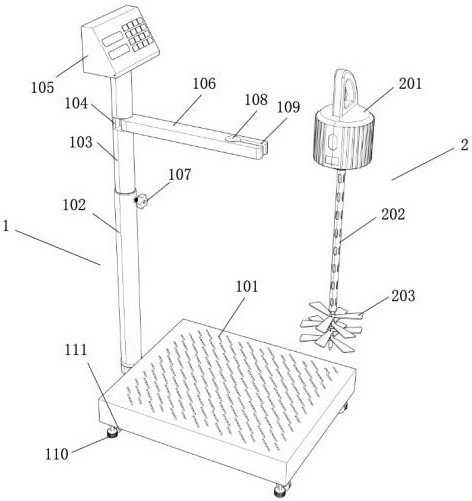

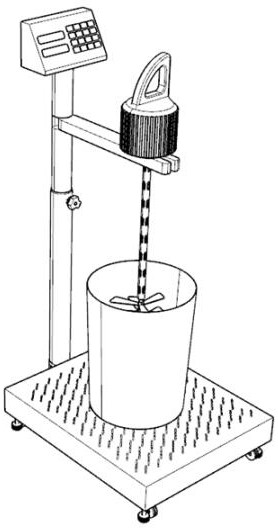

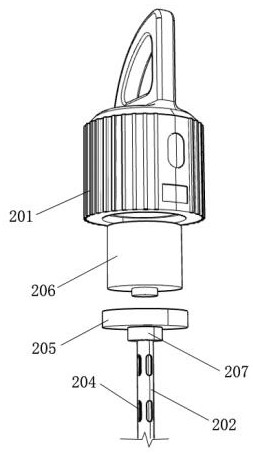

Multi-component adhesive mixing device and mixing method thereof

PendingCN111729604AAccurately control the dosageImprove mixing uniformityRotary stirring mixersTransportation and packagingAdhesive cementElectric machinery

The invention discloses a multi-component adhesive mixing device and a mixing method thereof. The multi-component adhesive mixing device comprises a weighing device and an adhesive stirring device which is arranged on the weighing device, wherein the weighing device comprises a weighing instrument, a height adjusting rod fixedly arranged on the weighing instrument, a display arranged at the top ofthe height adjusting rod and a rotary supporting rod movably arranged on the height adjusting rod; the glue stirring device comprises a shell, a hollow shaft motor arranged at the bottom of the shell, a stirring rod arranged on the hollow shaft motor and a stirring paddle fixedly arranged on the stirring rod. The beneficial effects of the invention are that the device can achieve the precise control of the use amount of an adhesive through the weighing device, enables the proportion of all components to be more reasonable, and irons out the defects that the use amount is uncontrollable and the waste is liable to be caused when the adhesive is manually blended; and the multi-component adhesive can be mixed through the arranged stirring device, so that the mixing uniformity and the workingefficiency of the adhesive are improved.

Owner:ZHEJIANG YASHA DECORATION

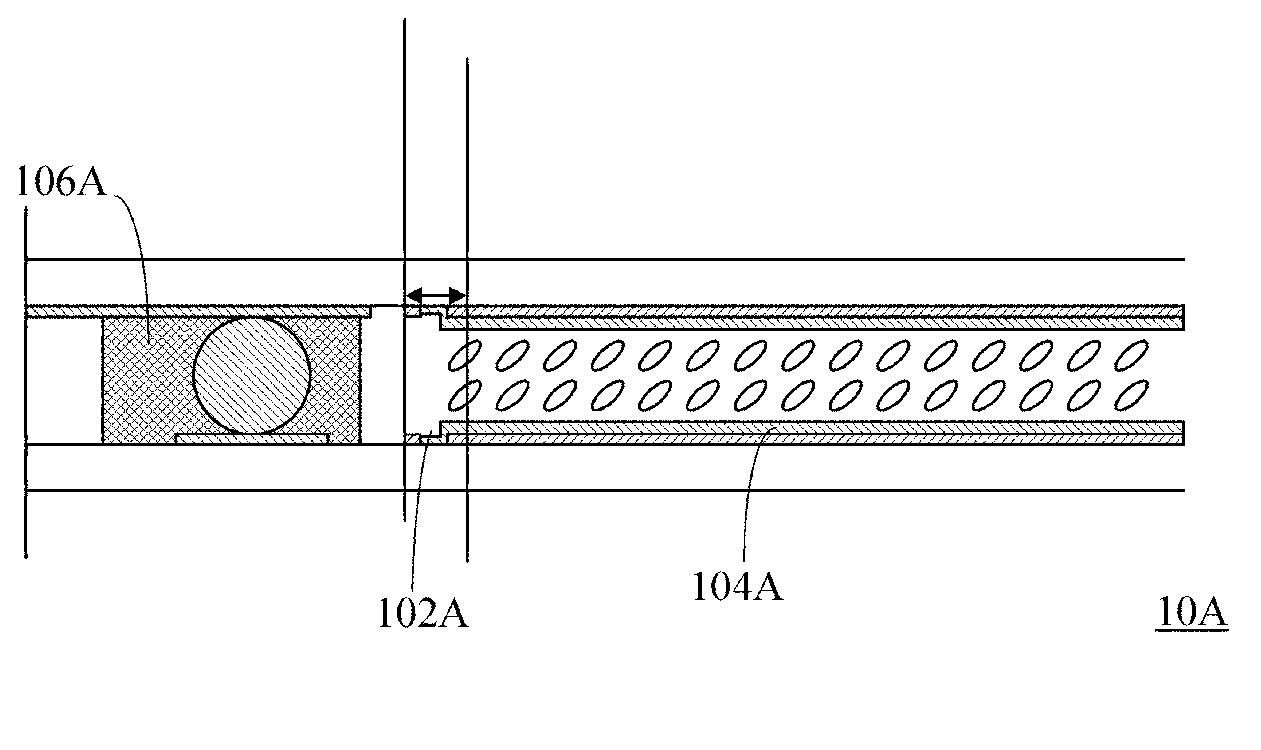

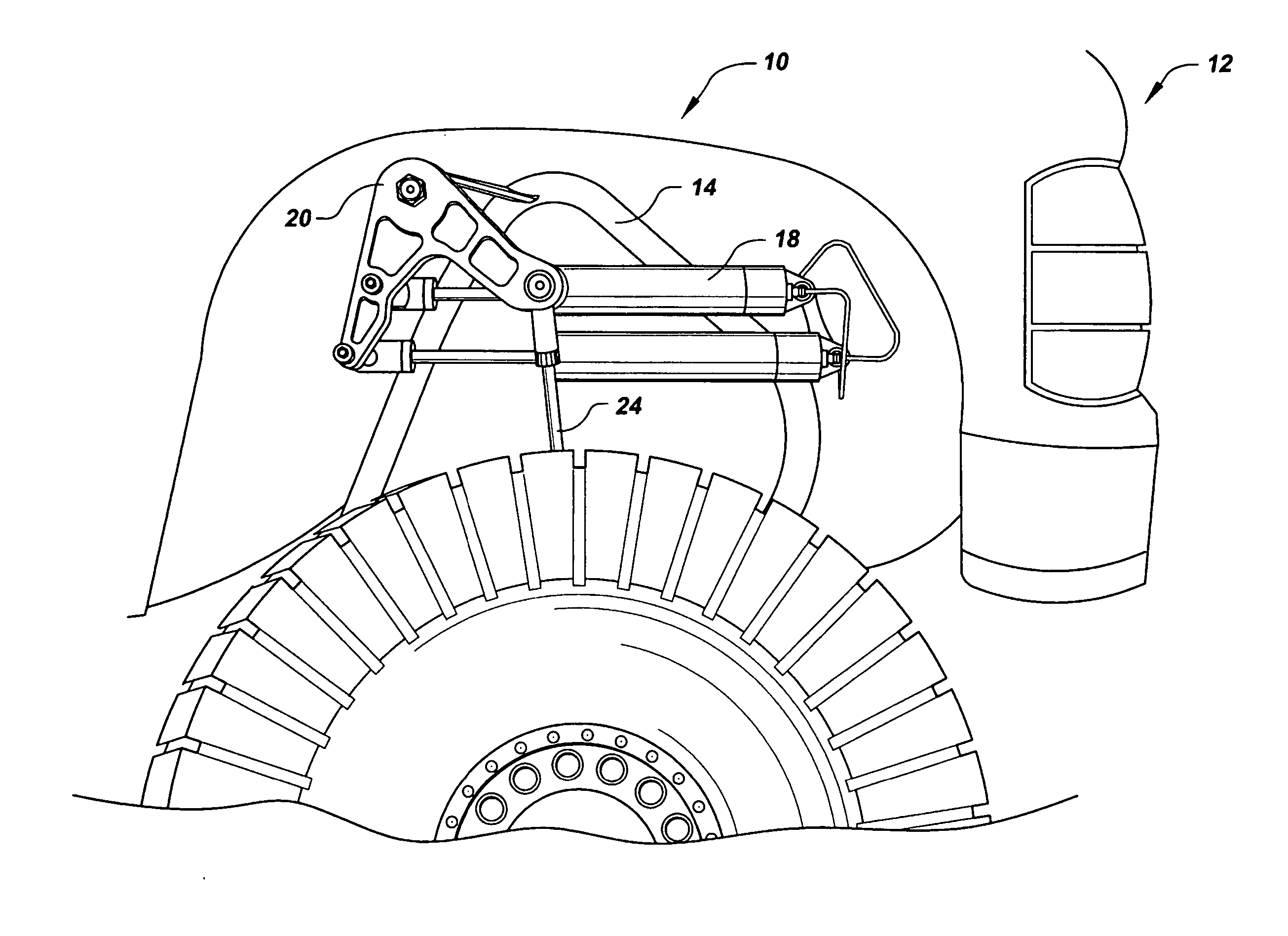

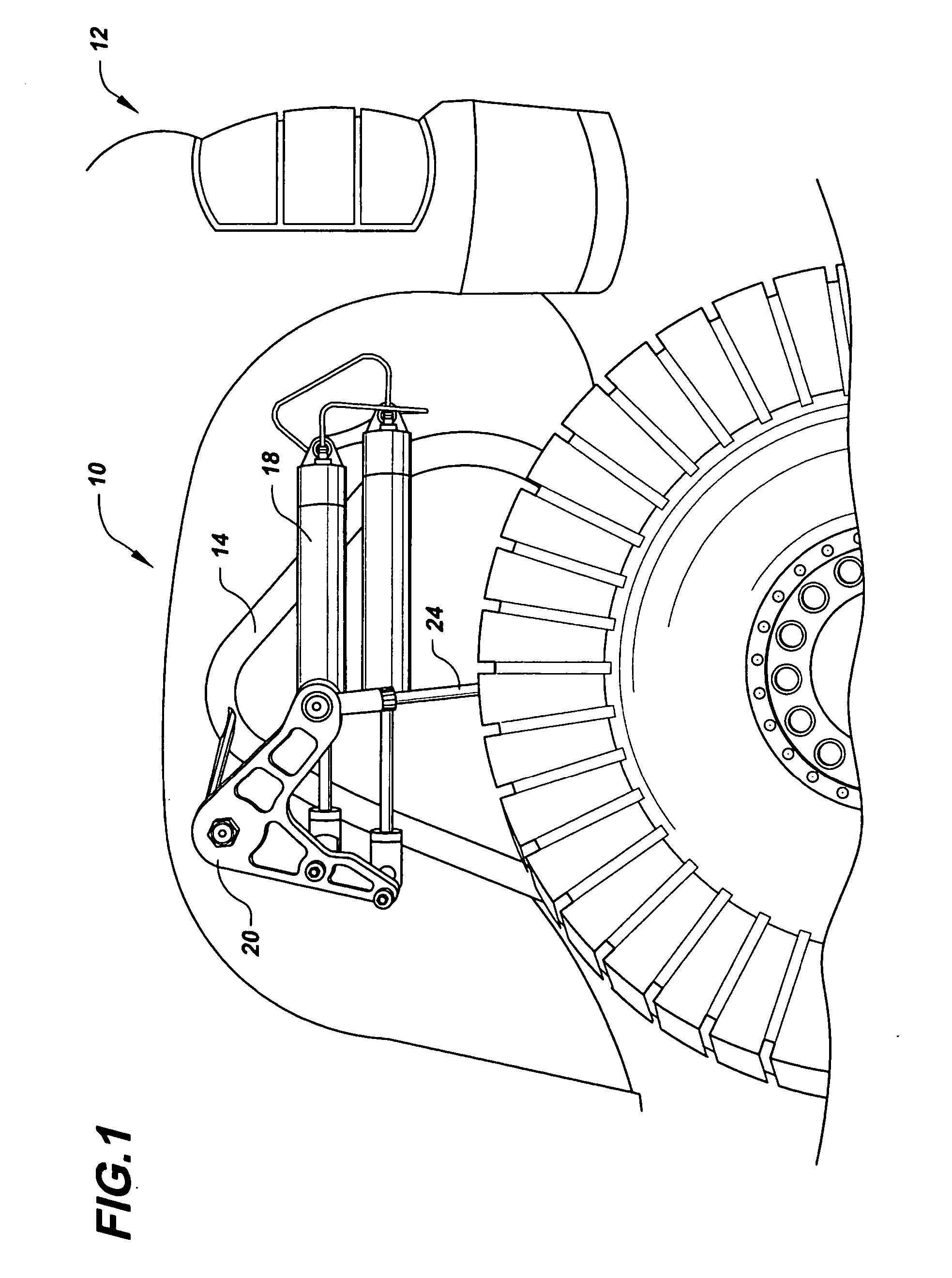

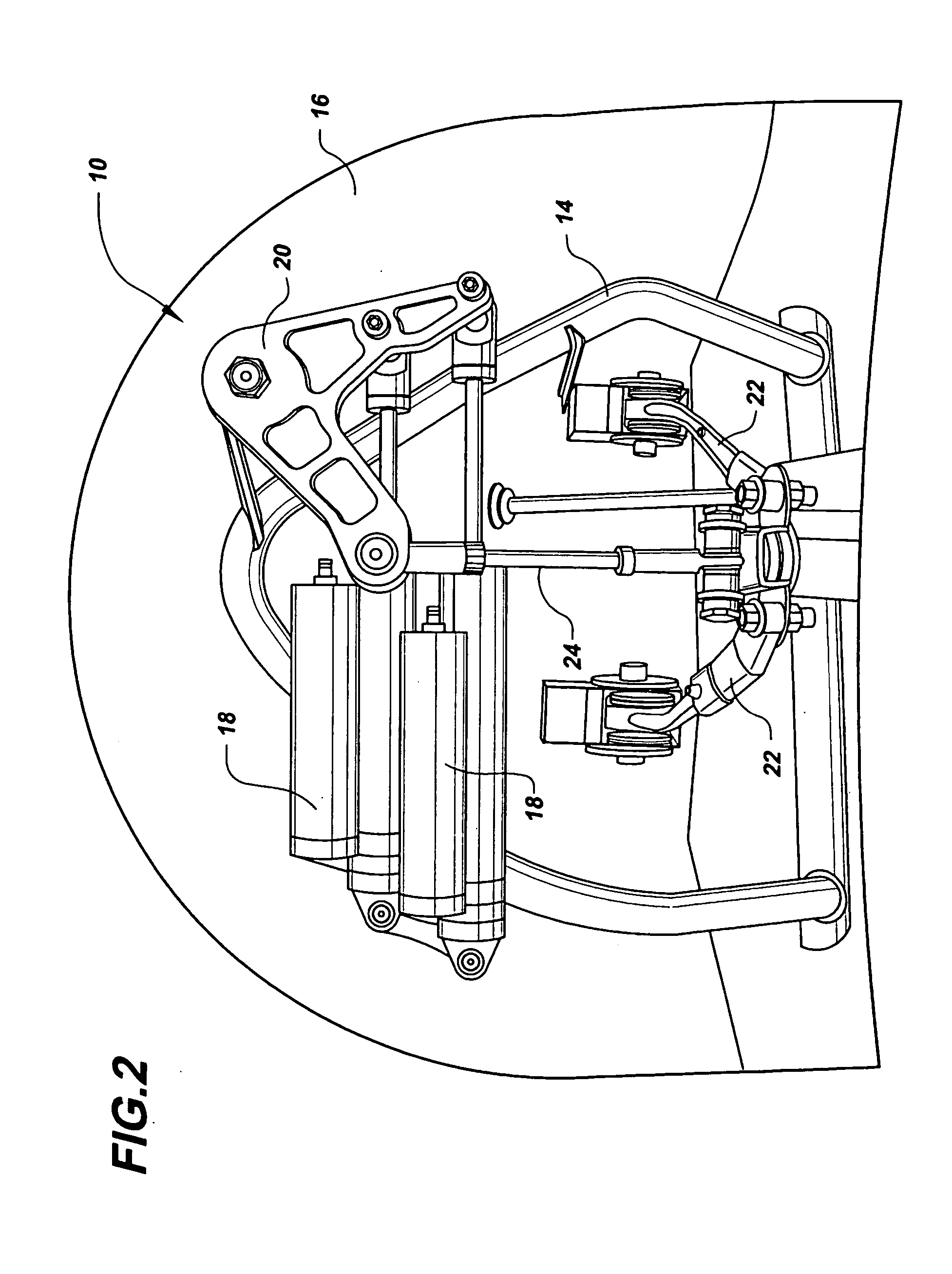

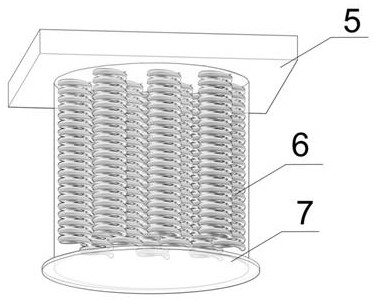

Horizontal shock suspension system

InactiveUS20050253354A1Affect ride qualityImprove efficiencyRigid suspensionsResilient suspensionsEngineeringShock absorber

A horizontally mounted vehicle suspension system is provided. The suspension system contains at least one horizontally mounted shock, which provides for a more comfortable ride within the vehicle. The configuration increases the space to accommodate for the shock or shock strut, as well as allows for the use of full travel shocks in small spaces. The full shock length, with all associated benefits can be used within a smaller space. The suspension system may be used with traditional shock absorbers or shock struts.

Owner:RIZE INDS

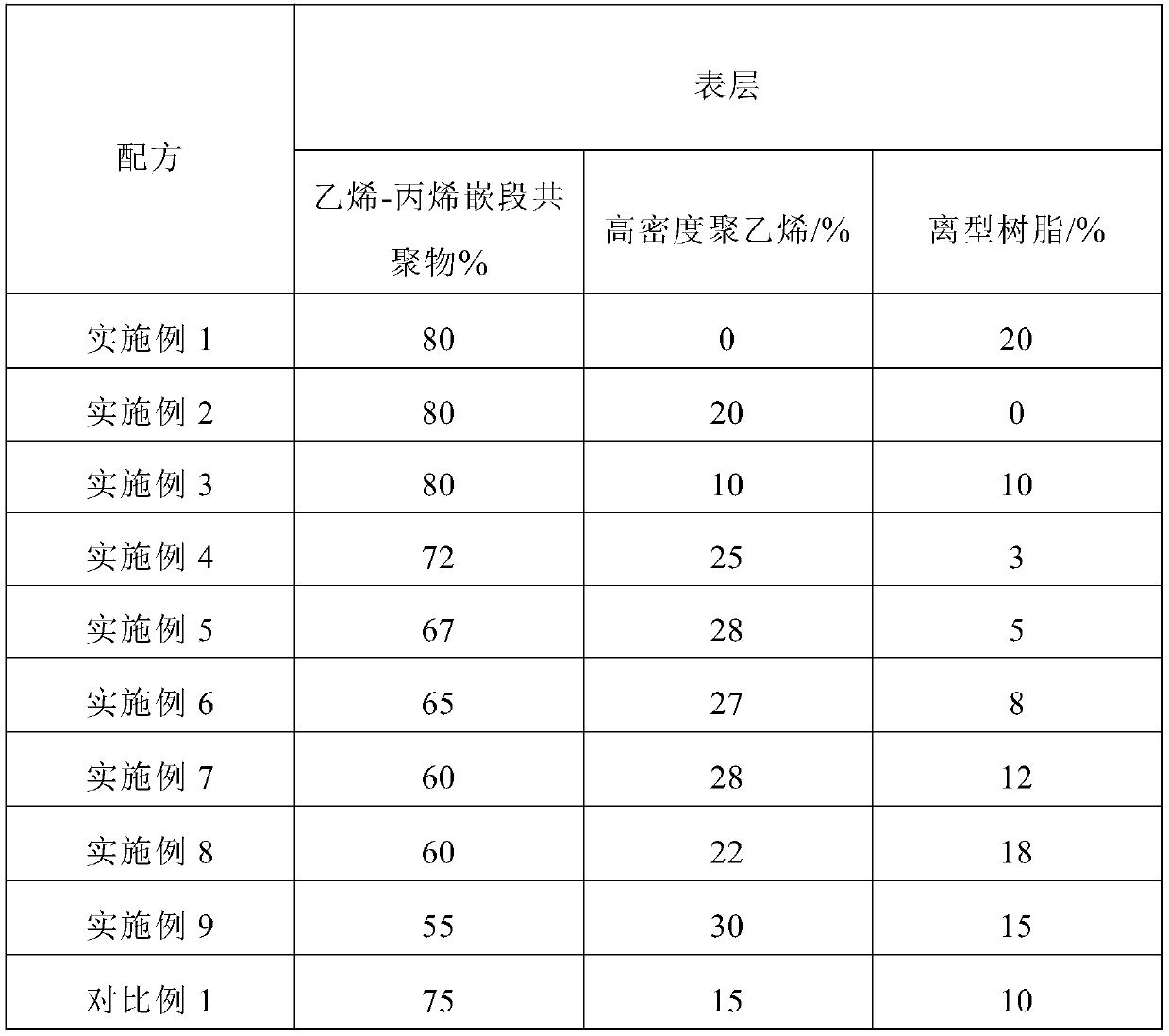

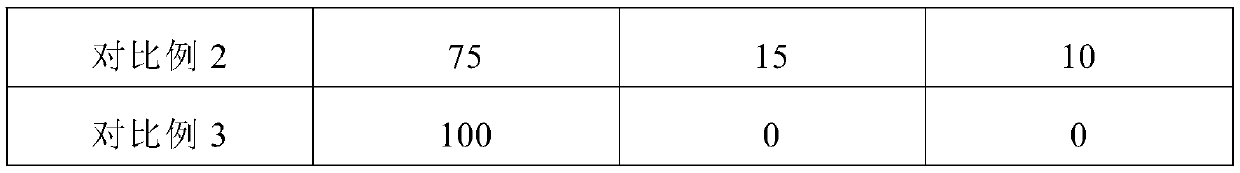

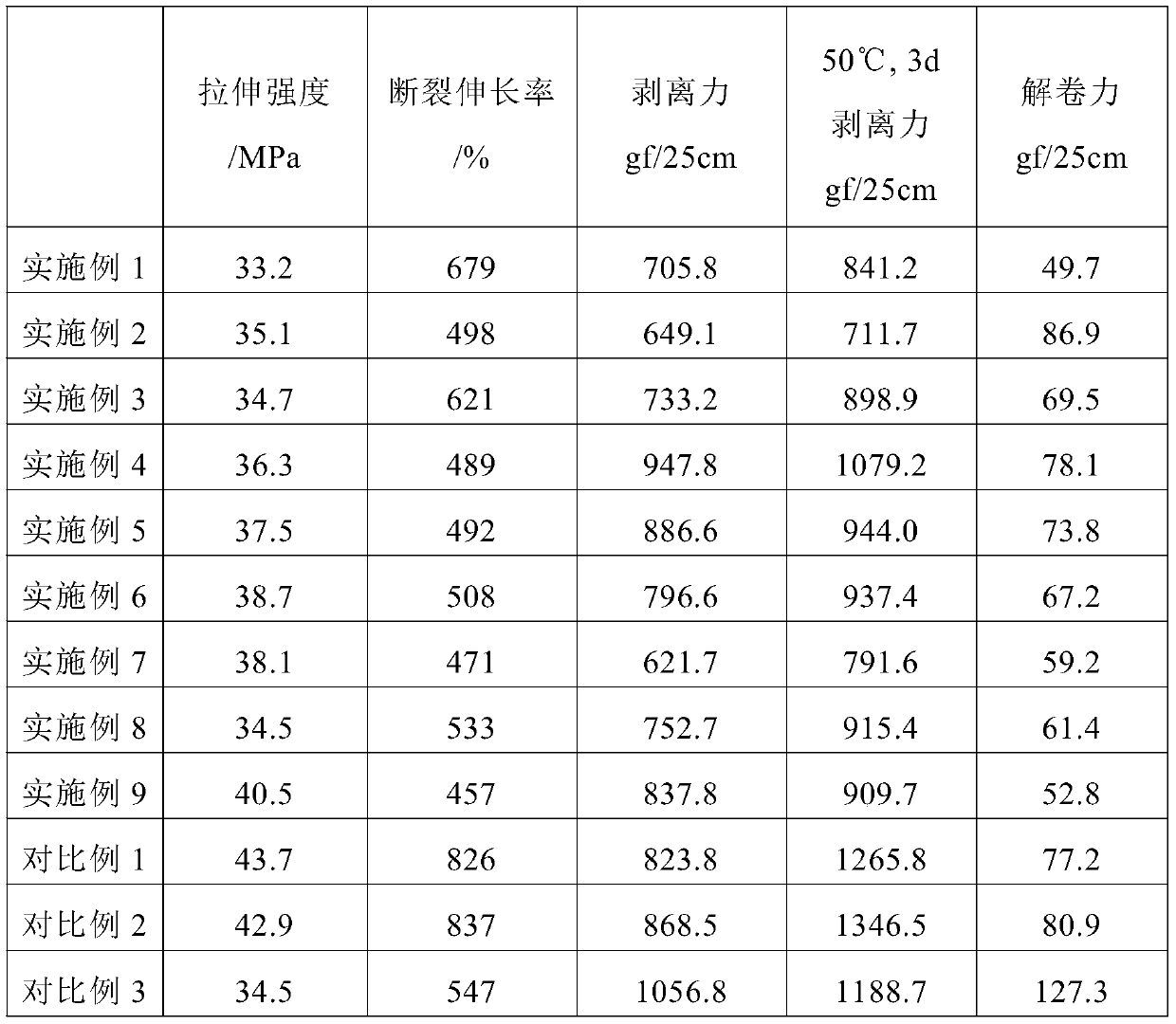

Novel high-viscosity protective film and preparation method thereof

The invention relates to the field of protective film materials, and particularly relates to a novel high-viscosity protective film and a preparation method thereof. In order to solve the problems that in an unwinding process of the high-viscosity protective film, a surface layer is easily adhered to an adhesive layer and peeling is difficult, the invention provides the novel high-viscosity protective film and the preparation method thereof. The high-viscosity protective film sequentially comprises a surface layer, a core layer and an adhesive layer; the surface layer comprises 55-80% of an ethylene-propylene block copolymer, 0-30% of high-density polyethylene and 0-20% of release resin, wherein the total amount of the high-density polyethylene and the release resin is 20-45%. The protective film is high in adhesive force and good in attaching effect, the change of adhesive force is small along with temperature and time, peeling is easy, residual adhesive is avoided, unwinding is easy,and the novel high-viscosity protective film is suitable for being used as an optical material surface protective film with high viscosity requirements.

Owner:NINGBO EXCITON TECH

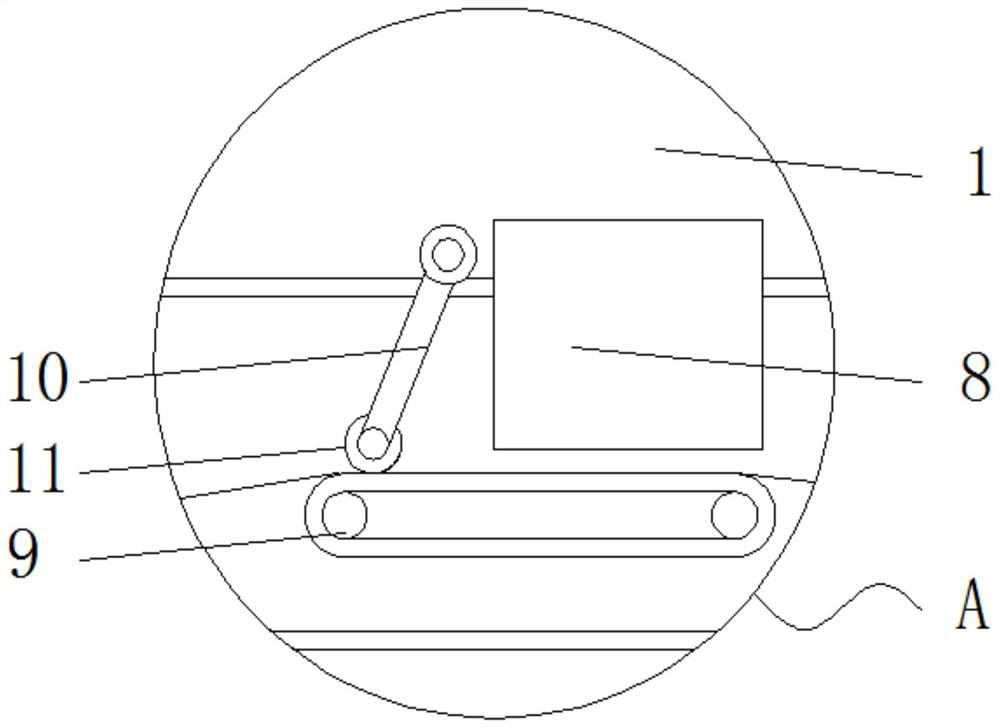

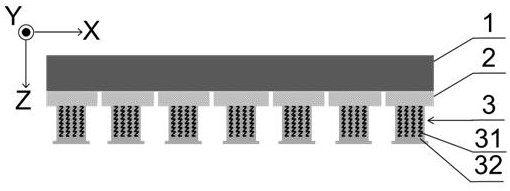

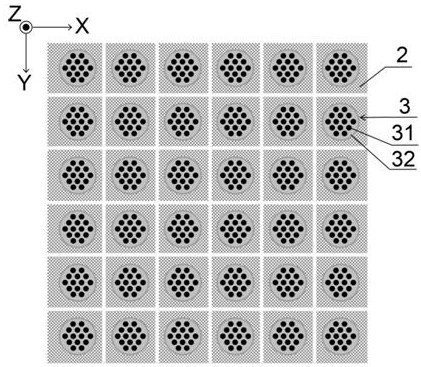

Micro device transfer device and transfer method

ActiveCN112133667AAvoid displacementAvoid damageSolid-state devicesSemiconductor/solid-state device manufacturingElastomerTemperature control

The invention discloses a micro device transfer device and transfer method; the micro device transfer device comprises a temperature control substrate, a morphology adaptation layer and adhesion unitsarranged in an array; each adhesion unit comprises an elastomer and a temperature control element group arranged in the elastomer and used for controlling the temperature of the elastomer, and the elastomer of each adhesion unit is of a micron-scale columnar structure. The elastomer is made of an entropy elastic material, and the temperature control element group is electrically connected with the temperature control substrate. In the transferring process, according to the weight and the shape of a target transferring device, the target temperature of the corresponding adhesion unit is set through the temperature control substrate, and the device is picked up and transferred to the target position after being in good contact with the target device; the temperature control element group ispowered off, the adhesion units are separated from the target device, and device transfer is completed. The adhesive force can be adjusted as required, stress on the device in the transfer process can be basically prevented, and the device and method are particularly suitable for transfer of high-precision devices and ultrathin devices.

Owner:WUHAN UNIV

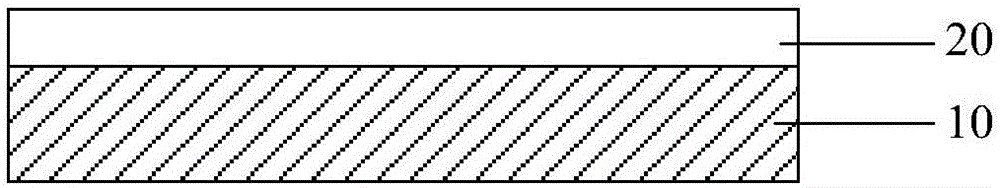

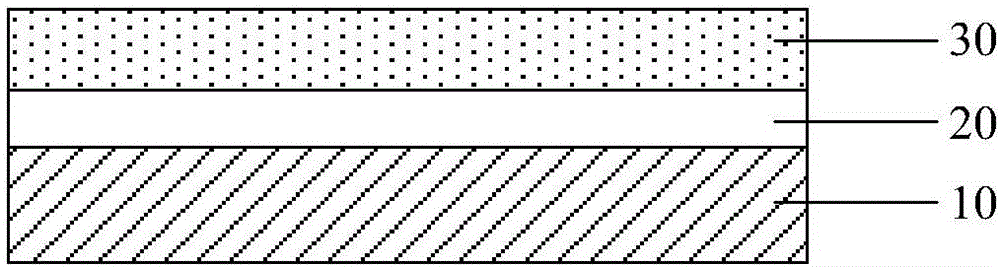

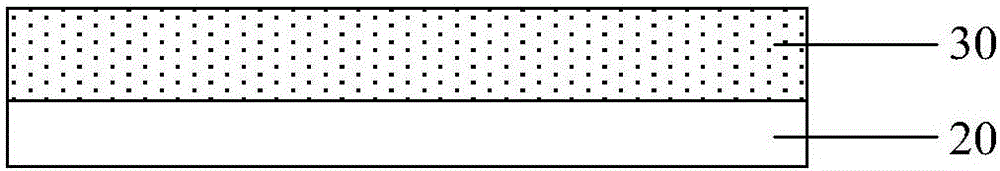

Transfer method of graphene film and base plate

The embodiment of the invention provides a transfer method of a graphene film and a base plate, relating to the technical field of display. The method can improve the phenomenon of cracking of the graphene film in the transfer process, enhances the adhesiveness of the graphene film on the target base plate, and implements transfer of the large-size graphene film. The method comprises the following steps: forming a support layer on a first substrate on which a graphene film is grown, wherein the support layer is formed on one side of the graphene film away from the first substrate; bonding the side of the first substrate with the support layer with the target base plate through a transparent adhesive layer; and removing the first substrate.

Owner:BOE TECH GRP CO LTD

Stainless steel vessel with enamel coating and preparation method thereof

The invention discloses a stainless steel vessel with an enamel coating and a preparation method thereof, and belongs to the technical field of stainless steel vessels. The preparation method comprises the following steps: firstly, sandblasting the stainless steel surface of a stainless steel vessel embryo to form a rough surface on the surface of the stainless steel vessel embryo; then, coating the stainless steel surface of the stainless steel vessel embryo with ground coat slurry, specifically, the coating thickness of the ground coat slurry is 60-100 [mu]m; drying and then sintering the stainless steel vessel embryo with the ground coating; coating the surface of the sintered stainless steel vessel embryo with cover coat slurry, specifically, the coating thickness of the cover coat slurry is 170-230 [mu]; and finally, drying and then sintering the stainless steel vessel embryo with the cover coating, and after the sintering is completed, obtaining the target stainless steel vessel.The preparation method is simple, and the enamel coating can adhere more firmly to the surface of the stainless steel alloy.

Owner:宁波好物家居用品设计有限公司 +1

Molecular transfer lithography apparatus and method for transferring patterned materials to a substrate

InactiveUS8499810B2Affect adhesionInhibition formationNanoinformaticsPhotomechanical apparatusWater bathsLithographic artist

A system and method to implement a molecular transfer lithography process is described. A destroyable nanopatterned template coated with functional material is attached to a removable carrier that is held suspended over a substrate, and a shaped pressure pad brings the functional material into contact with the substrate, initiating adhesion of the functional material to the surface of the substrate, and then detracting the pressure pad from the substrate. The substrate with destroyable template and removable carrier is then sent for further processing. In a preferred embodiment, the system and method are used to process a patterned polyvinyl alcohol template coated with a functional material that is thermal adhered to a substrate and after pressing, subjected to a water bath to dissolve away the template and carrier, leaving the functional material patterned on the substrate.

Owner:TRANSFER DEVICES

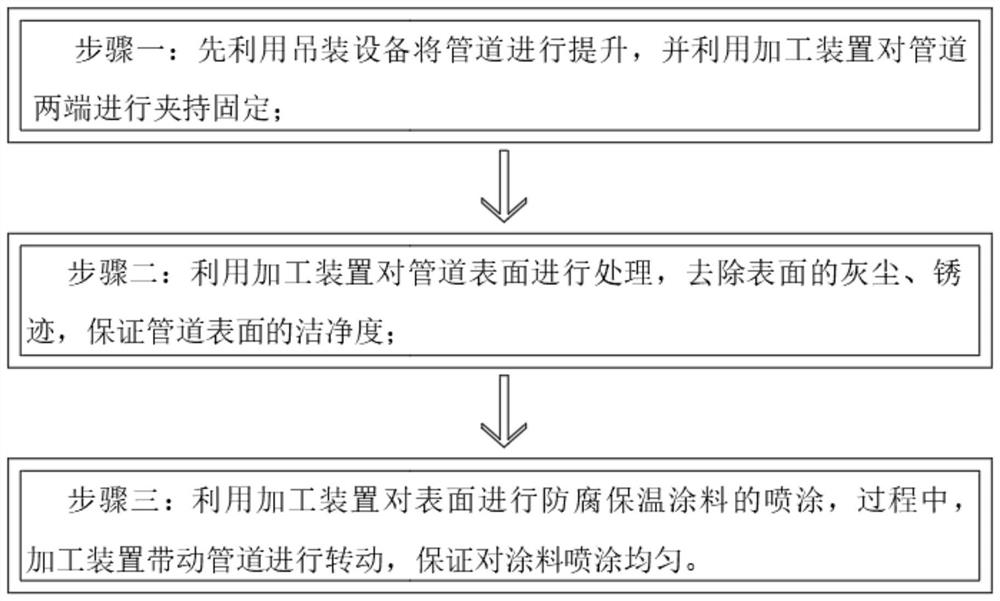

Construction process of anti-corrosion thermal insulation coating

PendingCN114833052AAffect adhesionImprove cleanlinessHollow article cleaningLiquid spraying apparatusThermal insulationHeat conservation

The invention discloses an anti-corrosion heat-preservation coating construction technology, and relates to the technical field of building pipeline machining, the anti-corrosion heat-preservation coating construction technology is based on a machining device, and the anti-corrosion heat-preservation coating construction technology specifically comprises the following steps that firstly, a pipeline is lifted through lifting equipment; the machining device is used for clamping and fixing the two ends of the pipeline; secondly, the surface of the pipeline is treated through a machining device, dust and rust on the surface are removed, and the cleanliness of the surface of the pipeline is guaranteed; thirdly, the machining device is used for spraying the corrosion-resistant heat-preservation coating to the surface, in the process, the machining device drives the pipeline to rotate, and it is guaranteed that the coating is evenly sprayed; according to the dust removal device, the extension rod of the dust removal device extends to push the sponge base plate and the cambered surface sponge block to make contact with the surface of a pipeline, the cambered surface sponge block wipes the surface of the pipeline, dust and rust powder generated in the rust removal process are removed, and the cleanliness of the surface of the pipeline is guaranteed.

Owner:杨凤娇

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com