Novel high-viscosity protective film and preparation method thereof

A protective film, high-viscosity technology, applied in the direction of adhesives, film/sheet-like adhesives, etc., can solve the problems of easy adhesion between the surface layer and the adhesive layer, and it is not easy to peel off, so as to achieve a small effect on the adhesive force with temperature and time changes, Easy peeling, good sticky effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

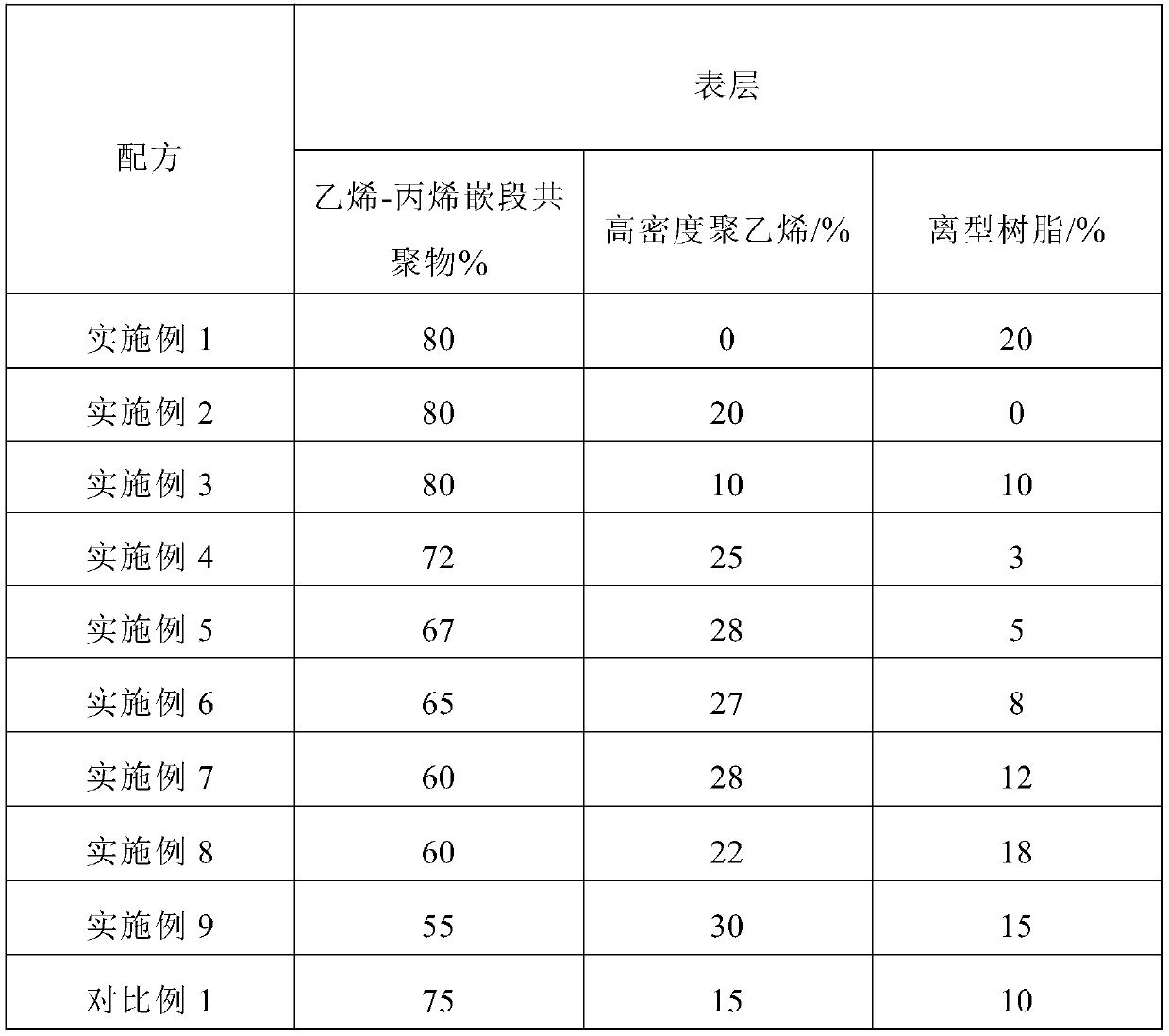

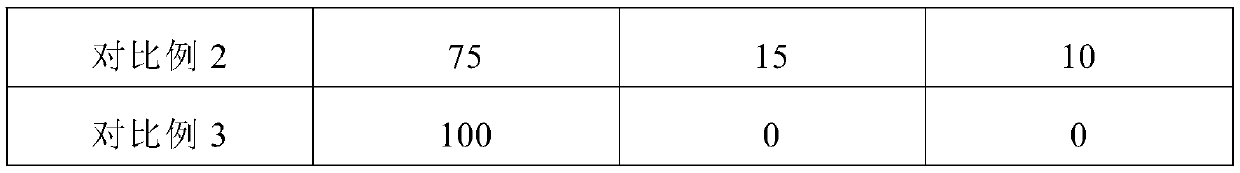

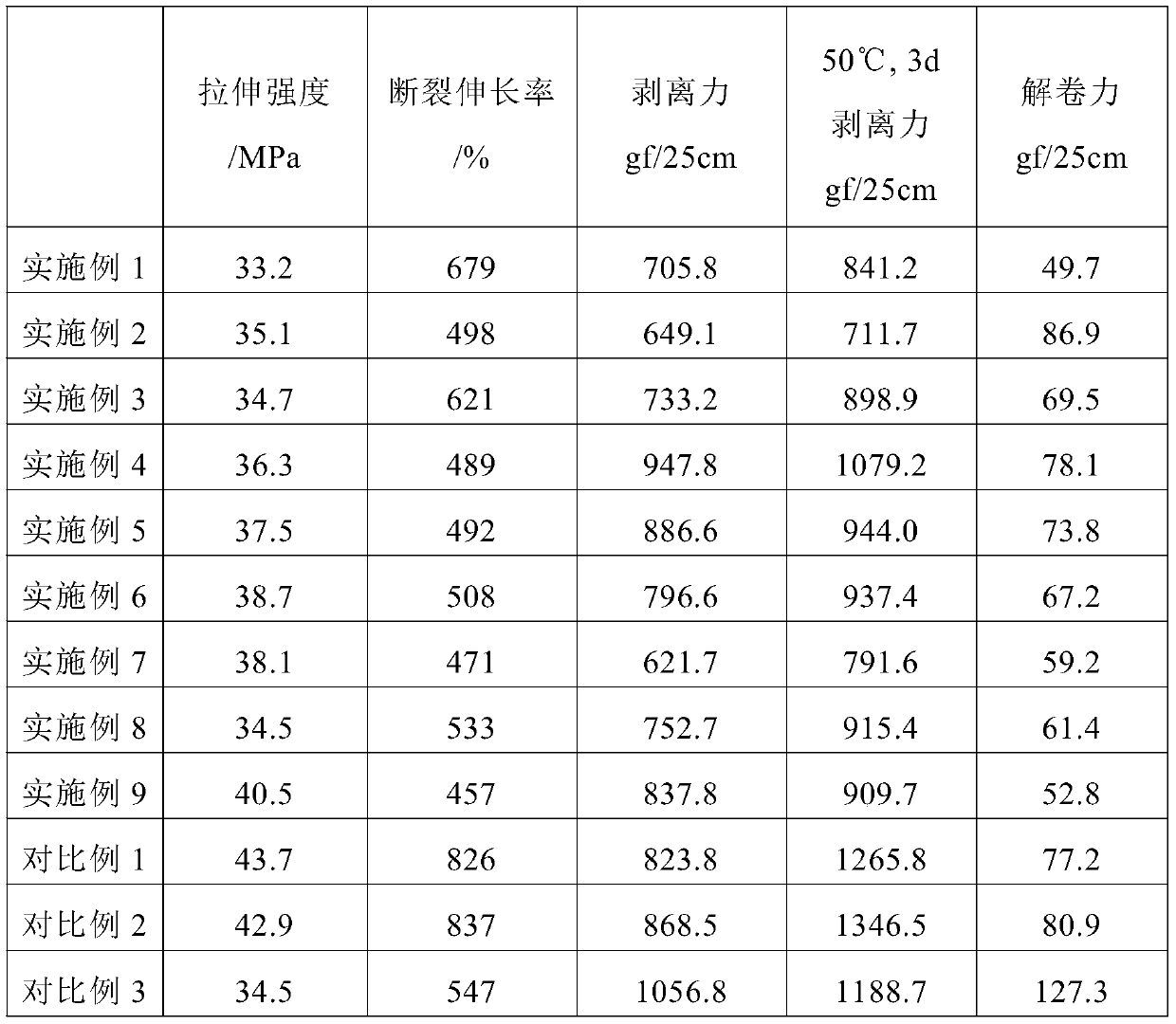

Embodiment 1

[0029] The novel high-viscosity protective film provided by the invention sequentially comprises a surface layer, a core layer and an adhesive layer.

[0030] The surface layer is made of ethylene-propylene block copolymer and release resin at a ratio of 80%:20%. The density of ethylene-propylene block copolymer is 0.90g / cm 3 , The melt index is 9.0g / 10min. The release resin is a vinyl polymer chemically modified by styrene (produced by Mitsubishi Chemical, the brand is W200P).

[0031] The core layer adopts ethylene-propylene block copolymer with a weight percentage of 100%, and its density is 0.90g / cm 3 , The melt index is 5.0g / 10min.

[0032] The adhesive layer adopts methyl methacrylate-butyl acrylate-methyl methacrylate block copolymer with a density of 1.13g / cm 3 , The melt index is 1.2g / 10min.

[0033] The surface layer had a thickness of 10 μm, the core layer had a thickness of 30 μm, and the adhesive layer had a thickness of 10 μm.

Embodiment 2

[0035] As the novel high-viscosity protective film that embodiment 1 provides, the difference is:

[0036] The surface layer is made of ethylene-propylene block copolymer and high-density polyethylene at a ratio of 80%:20%. The density of ethylene-propylene block copolymer is 0.90g / cm 3 , The melt index is 9.0g / 10min. The density of high-density polyethylene is 0.945g / cm 3 .

Embodiment 3

[0038] As the novel high-viscosity protective film that embodiment 1 provides, the difference is:

[0039] The surface layer is made of ethylene-propylene block copolymer, high-density polyethylene and release resin at a ratio of 80%:10%:10%. The density of ethylene-propylene block copolymer is 0.91g / cm 3 , The melt index is 4.0g / 10min. The density of high-density polyethylene is 0.963g / cm 3 . The release resin is a vinyl polymer chemically modified by styrene (produced by Mitsubishi Chemical, the brand is W200P).

[0040] The adhesive layer adopts methyl methacrylate-butyl acrylate-methyl methacrylate block copolymer. Its density is 1.11g / cm 3 , The melt index is 1.5g / 10min.

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| melt flow index | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com