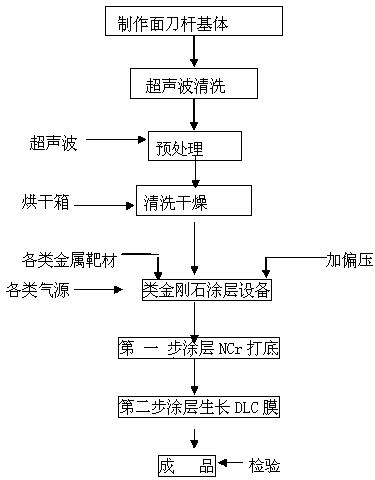

Preparation process of chromium oxynitride and diamond-like carbon film composite coating fine dried noodle knife roller

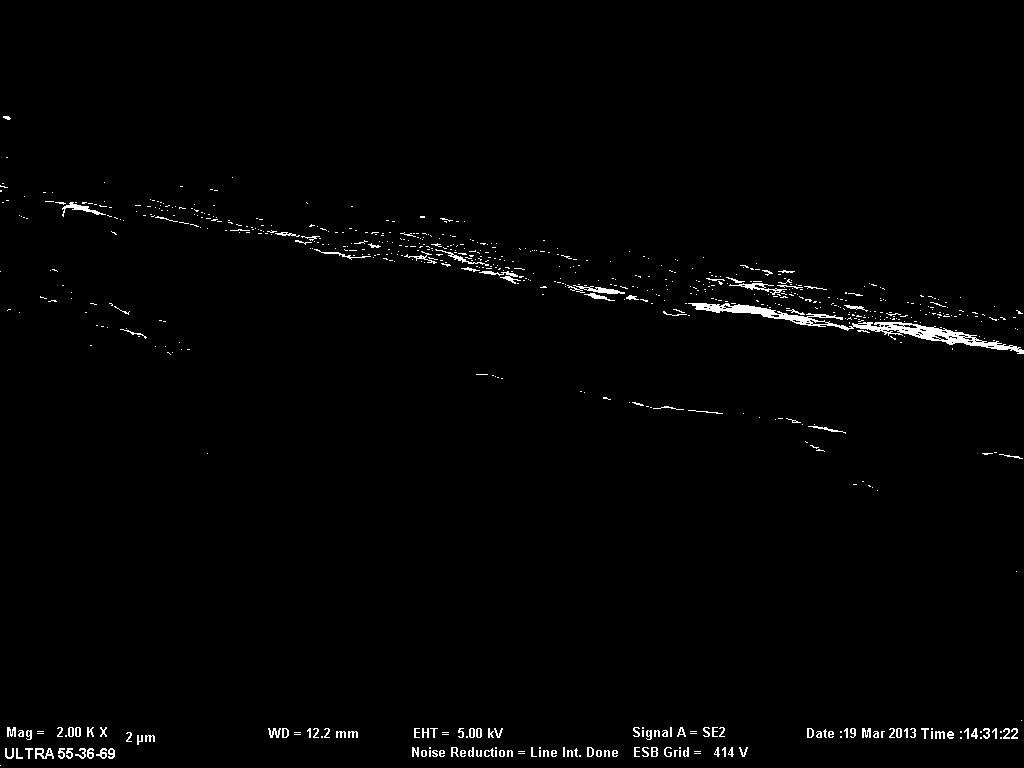

A technology of diamond-like film and composite coating, applied in metal material coating process, coating, ion implantation coating and other directions, can solve the problems such as the lack of affinity of the coating, the short service life of the blade, and the easy breeding of bacteria, etc. To achieve the effect of excellent surface morphology, uniform thickness and excellent composition quality of the coating

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0033] Embodiment 1, taking a 550×1.5mm round knife thickened noodle knife (referred to as "workpiece") as an example:

[0034] Step 1: Cleaning and drying: Clean and remove the large grooves and small grooves densely covered with rust-proof oil and stains on the surface of the knife rod in a constant temperature drying room, and use metal detergent and degreaser for cleaning in a weight ratio of 1:1 The liquid cleaning and drying linkage device puts the cleaned workpiece into the drying oven, the temperature is controlled at 60°C, and the dried workpiece is loaded into the special fixture to enter the next step. The cleaning and drying linkage device adopts a high-pressure spray cleaning machine;

[0035] The second step: workpiece pretreatment sandblasting: spray the outer circle with diamond W10 micropowder, and use physical methods to etch the surface of the workpiece, so that the coated diamond-like film forms the frame foundation;

[0036] The third step: pretreatment a...

Embodiment 2

[0048] Example 2: Take the 330×1.5mm thickened noodle knife as an example:

[0049] The first step: cleaning and drying: clean and remove the large grooves and small grooves densely covered on the surface of the knife rod in a constant temperature drying room. The liquid cleaning and drying linkage device puts the cleaned workpiece into the drying oven, and the temperature is controlled at 60-70°C. The dried workpiece is loaded into the special fixture to enter the next step.

[0050] The cleaning and drying linkage device is: the high-pressure spray cleaning machine is sent to the workpiece to be cleaned by the conveyor belt or the suspension line, and after a certain procedure, the workpiece is degreased, cleaned, dried, and then automatically sent out by the conveyor belt;

[0051] The second step: workpiece pretreatment sandblasting: spray the outer circle with diamond W10 micropowder, and use physical methods to etch the surface of the workpiece, so that the coated diamon...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| adhesivity | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com