Construction process of anti-corrosion thermal insulation coating

A construction technology and thermal insulation coating technology, which is applied in the field of anti-corrosion thermal insulation coating construction technology, can solve the problems of affecting coating adhesion, metal pipe surface corrosion, and affecting the effect of spraying paint, so as to ensure the thickness of spraying and the quality of spraying

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

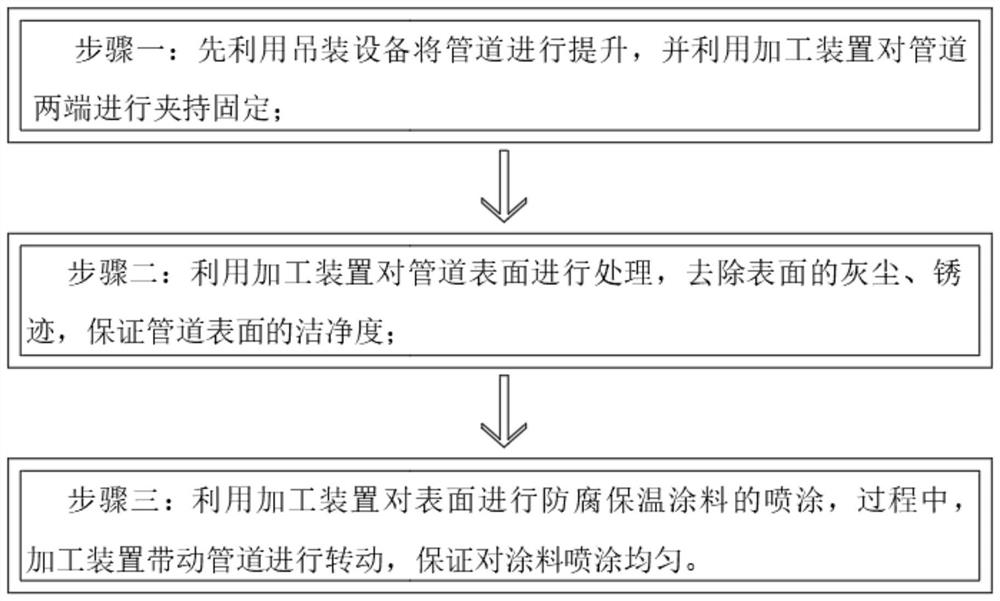

[0041] like Figure 1 to Figure 8 As shown, the embodiment of the present invention provides an anti-corrosion thermal insulation coating construction process, the anti-corrosion thermal insulation coating construction process is based on a processing device, and the anti-corrosion thermal insulation coating construction process specifically includes the following steps:

[0042] Step 1: First, lift the pipeline with hoisting equipment, and use the processing device to clamp and fix both ends of the pipeline;

[0043] Step 2: Use the processing device to treat the surface of the pipeline to remove dust and rust on the surface to ensure the cleanliness of the surface of the pipeline;

[0044] Step 3: Use the processing device to spray the surface with anti-corrosion and thermal insulation paint. During the process, the processing device drives the pipeline to rotate to ensure that the paint is sprayed evenly.

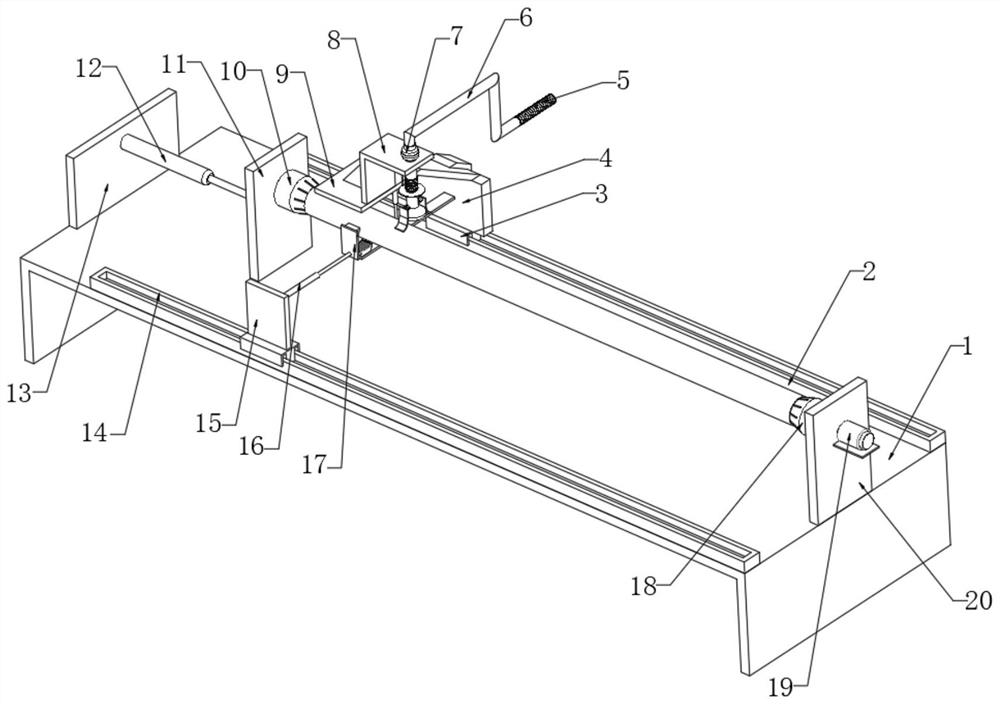

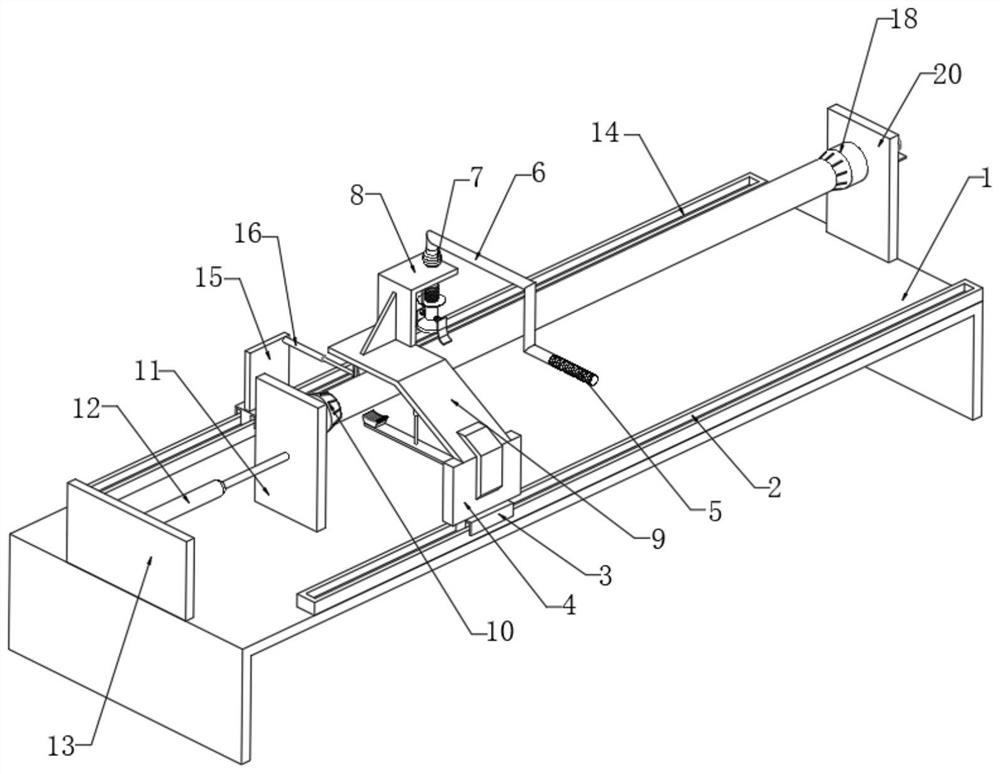

[0045] Further, the processing device includes a workbench 1, and ...

Embodiment 2

[0063] like Figures 9 to 10 As shown, in the processing device of this embodiment, compared with the first embodiment, an air cavity 38 is opened at the center of the driving cone-shaped clamping block 18 and the driven cone-shaped clamping block 10, and one end of the air cavity 38 is fixedly connected with an extension end. Pipe 36, two air cavities 38 are fixedly installed with a charging and discharging head 39 at one end of the two air chambers 38 away from the extension end pipe 36, the driving motor 19 is fixed on one side of the fixed side plate 20, and the output shaft of the driving motor 19 is connected with a drive The gear 191 is keyed to one end of the driving cone-shaped clamping block 18 with the driven gear plate 37 meshing with the driving gear 191 .

[0064] Further, a plurality of built-in end cylinders 40 are fixedly communicated with the inside of the two extension end tubes 36 , and the inner wall of each built-in end cylinder 40 is slidably connected w...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com