Micro device transfer device and transfer method

A micro-device transfer, micro-device technology, applied in semiconductor devices, electric solid-state devices, semiconductor/solid-state device manufacturing, etc., can solve problems such as easily damaged chips, pollution, failure, etc., to prevent unnecessary interference and reduce use costs , the effect of improving the range of adaptation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

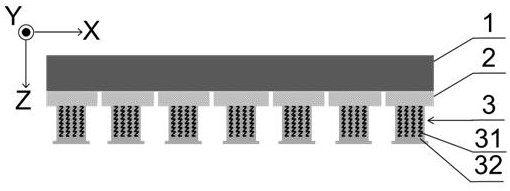

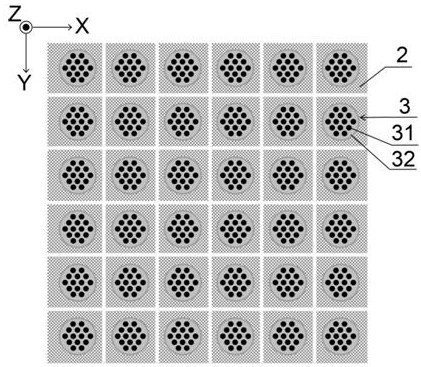

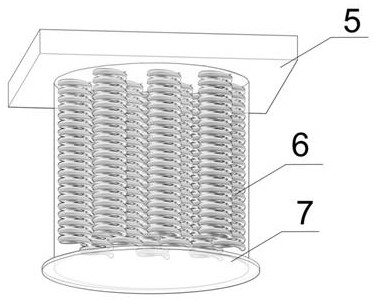

[0047] Such as Figure 1 to Figure 4 As shown, a micro-device transfer device is generally in the shape of a cube, including: a temperature-controlling substrate, a heat-insulating and insulating shape-adapting layer, and adhesive units arranged in multiple rows and columns. The adhesion unit includes an elastic body and a temperature control element group set in the elastic body for controlling its temperature. The elastic body of the adhesion unit is a micron-sized silicone rubber cylinder with a height of 10 microns and a diameter of 20 microns. The thickness of the column top sheet is 1 micron, The diameter is 24 microns; the internal temperature control element of the adhesion unit is a micron spiral column of metal material, and the spiral column is arranged in a hexagonal array to form a temperature control element group. A single spiral temperature control element is 8 microns in height and 4 in diameter. Microns.

[0048] Specifically, the morphology adaptation layer...

Embodiment 2

[0052] Based on the structural design of the controllable micro-device transfer device in Example 1, the shape adaptation layer can be replaced by a polyetheretherketone topological structure adaptation layer manufactured by additives, and the arrangement of the adhesion units can be replaced by a square arrangement, as shown in Figure 5 As shown, the internal temperature control element group of the adhesion unit is replaced by an array of micron wave-shaped temperature control elements made of ceramic material, and the elastomer can be replaced by ethylene-propylene rubber.

[0053] Specifically, the size of the adhesion unit is 10 microns in height and 15 microns in diameter, the thickness of the top sheet is 1 micron and 25 microns in diameter, and the size of a single internal temperature control element is 7 microns in height and 4 microns in width.

[0054] In the adhesion test of the adhesion unit, the test temperature ranges from 20 to 150 degrees Celsius.

Embodiment 3

[0056] Based on the structural design of the controllable micro-device transfer device in Example 1, the shape adaptation layer can be replaced by a polyether ether ketone topological structure adaptation layer manufactured by additives, and the arrangement of the adhesion units can be replaced by a square arrangement. The temperature control element group is an array of micron wave-shaped temperature control elements made of ceramic material, and the elastic body is ethylene-propylene rubber.

[0057] Specifically, the size of the adhesion unit is 11 microns in height and 14 microns in diameter, the thickness of the column top sheet is 1 micron and 24 microns in diameter, and the size of a single internal temperature control element is 8 microns in height and 5 microns in width.

[0058] In the adhesion test of the adhesion unit, the test temperature ranges from 20 to 160 degrees Celsius.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com