Method for protecting air film hole and tail split joint hole of blade

A technology of air film holes and blades, which is applied to the supporting elements of blades, engine elements, machines/engines, etc., can solve the problems of small size, difficult protection of air film holes, chemical corrosion of alloy substrates, etc., and achieves simple operation and detection. And easy to repair, environmentally friendly effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach 1

[0053] The blade protection process is as follows:

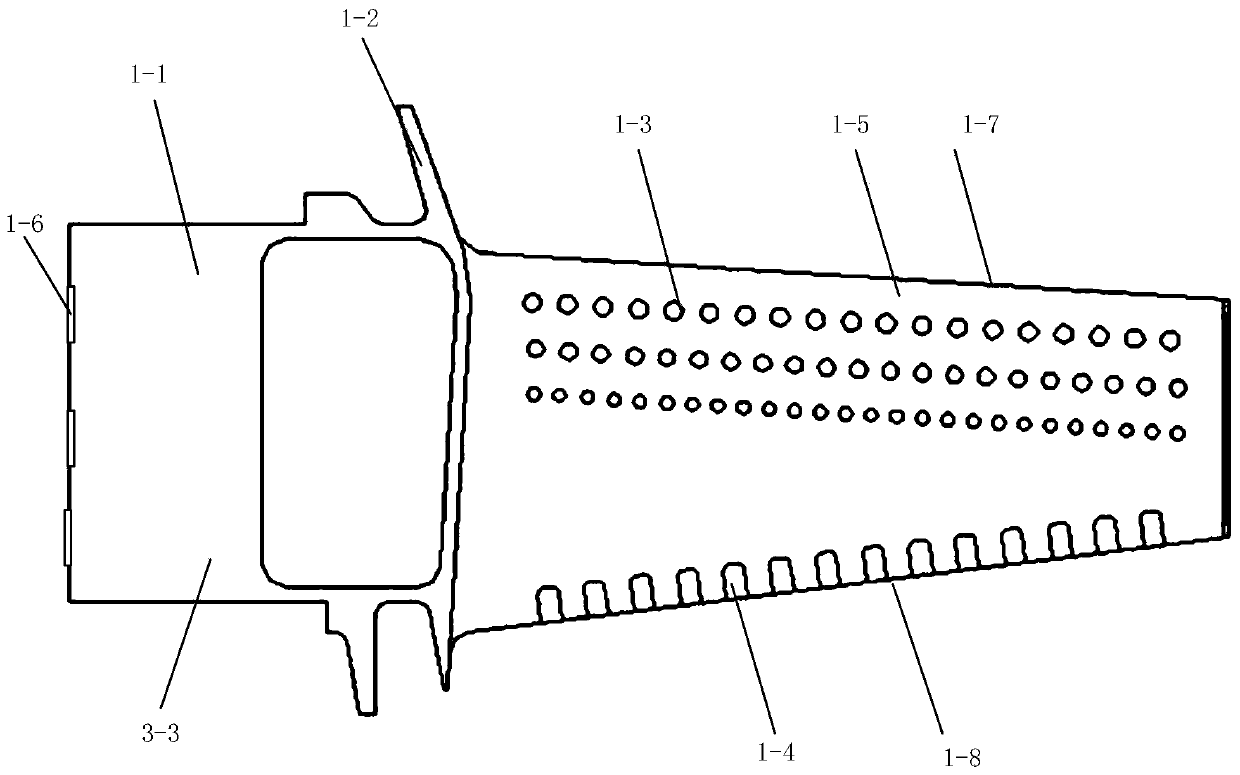

[0054] (1) Leaves 3-3 pre-treatment. Before protection, degrease the surface and inner cavity of the entire part, especially degrease the tenon 1-1, edge plate 1-2, air film hole 1-3, and split hole 1-4. The treatment method is: use acetone as the cleaning agent, soak the parts in the acetone solution, use the ultrasonic method to vibrate and clean for 10 minutes, then take it out and dry it with argon or compressed air;

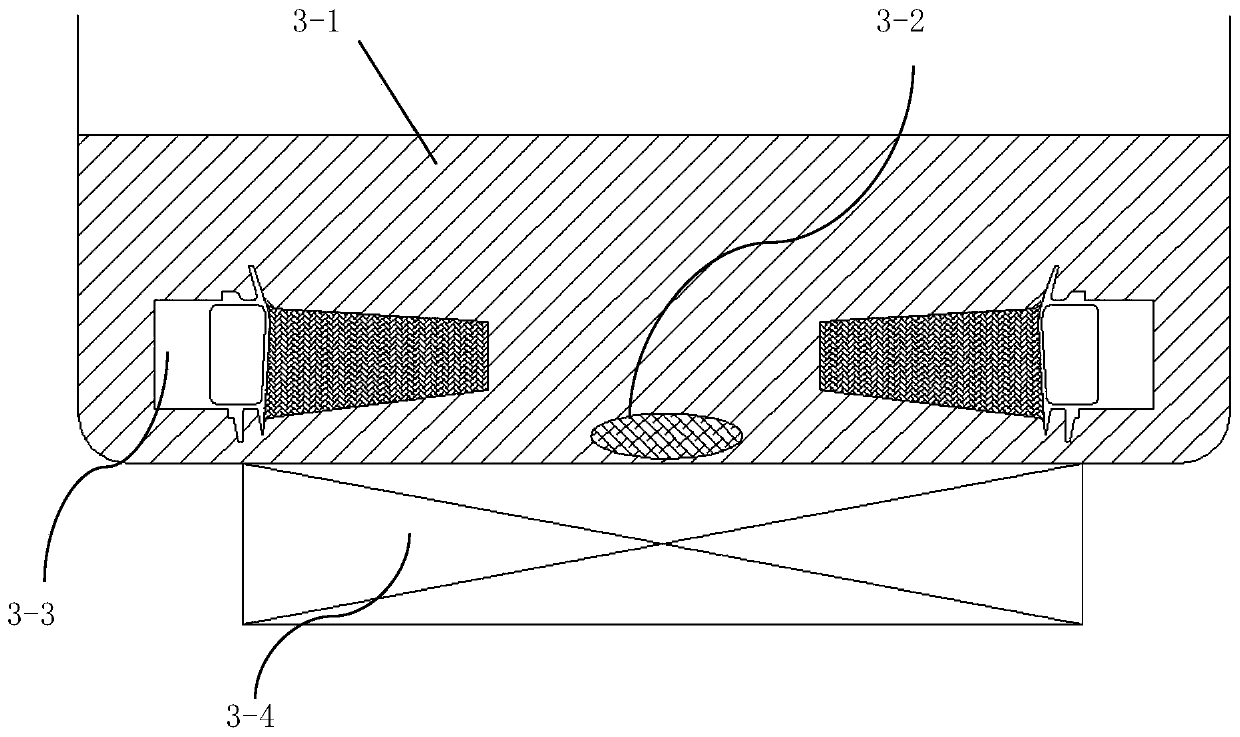

[0055] (2) Paraffin preparation. The paraffin wax is melted by using a magnetic stirrer 3-4 with a heating function, the set temperature is 50° C., the magnetic stirring speed is controlled by a gradual pulse speed, and the control speed range is 5-100 rpm.

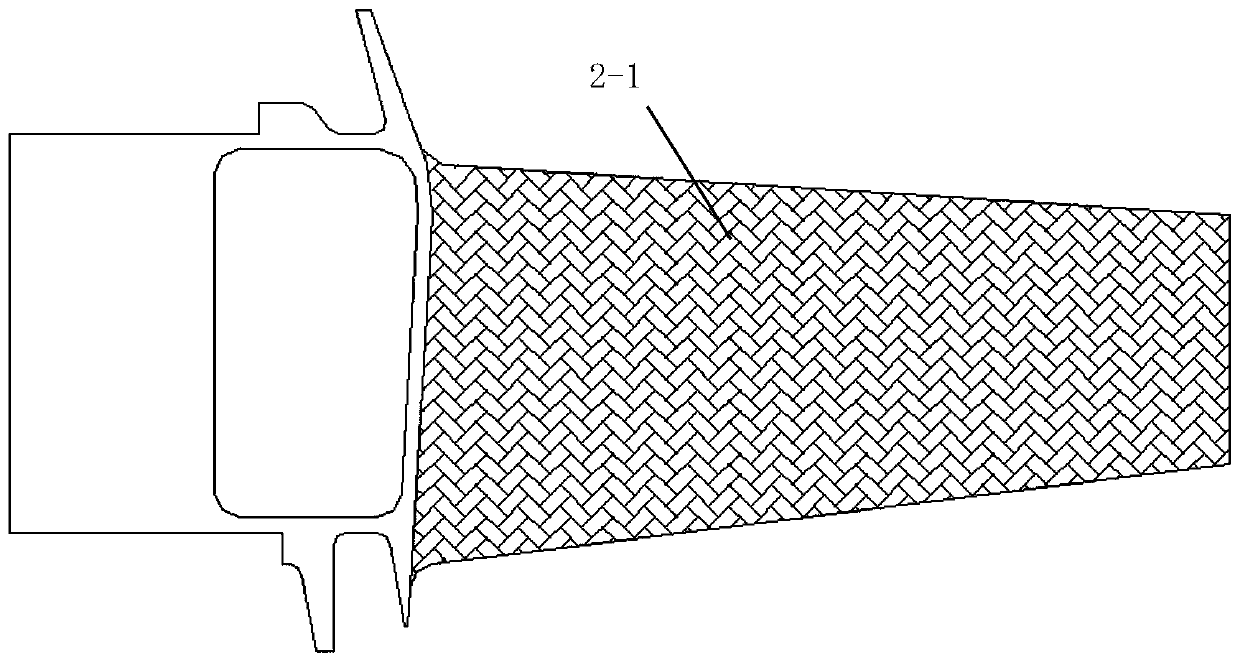

[0056] (3) Pressure-sensitive adhesive tape 2-1 protects the blade body 1-5. Use the pressure-sensitive adhesive tape 2-1 as the raw material for the protection of the blade body 1-5, paste the pressure-sensitive adhesive tape 2-1 along the width d...

Embodiment approach 2

[0063] The blade protection process is as follows:

[0064] (1) Leaves 3-3 pre-treatment. Before protection, degrease the entire part surface and inner cavity, especially for figure 1 The tenon 1-1, edge plate 1-2, air film hole 1-3, and tail split hole 1-4 are degreased. The treatment method is: use acetone as the cleaning agent, soak the parts in the acetone solution, Ultrasonic vibration cleaning is carried out for 60 minutes, and then it is taken out and dried with argon or compressed air;

[0065] (2) Paraffin preparation. The paraffin was melted by using a magnetic stirrer 3-4 with a heating function, the set temperature was 65° C., and the speed of the magnetic stirring was controlled by a gradual pulse speed, and the control speed range was 10-500 rpm.

[0066] (3) Pressure-sensitive adhesive tape 2-1 protects the blade body 1-5. Use the pressure-sensitive adhesive tape 2-1 as the raw material for the protection of the blade body 1-5, paste the pressure-sensitive a...

Embodiment approach 3

[0073] The blade protection process is as follows:

[0074] (1) Leaves 3-3 pre-treatment. Before protection, degrease the entire part surface and inner cavity, especially for figure 1 The tenon 1-1, edge plate 1-2, air film hole 1-3, and tail split hole 1-4 are degreased. The treatment method is: use acetone as the cleaning agent, soak the parts in the acetone solution, Vibrate and clean for 30 minutes by ultrasonic wave, then take it out and dry it with argon or compressed air;

[0075] (2) Paraffin preparation. The paraffin wax is melted by using a magnetic stirrer 3-4 with a heating function, the set temperature is 80° C., the magnetic stirring speed is controlled by a gradual pulse speed, and the control speed range is 100-1000 rpm.

[0076] (3) Pressure-sensitive adhesive tape 2-1 protects the blade body 1-5. Adopt pressure-sensitive adhesive tape 2-1 as the raw material for blade body 1-5 protection, paste pressure-sensitive adhesive tape 2-1 along the width directio...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com