Down leak-proofing fabric and processing method thereof

A processing method and anti-drilling down technology, which is applied in the field of textiles, can solve the problems of poor air permeability and wearing comfort of down products, decreased fabric feel and softness, and reduced anti-drilling down performance, so as to achieve excellent air permeability and improve use. The effect of experience, excellent tensile and elongation properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0016] A kind of processing method of anti-drilling velvet fabric, processing method is:

[0017] 1) Cut out several pieces of 60S cotton cloth and PE film with specifications of 41cm*41cm; (the cotton cloth and PE film are both purchased from the market)

[0018] 2) Glue spray coating: evenly spray WS-type hot melt adhesive (provided by Hefei Gaobeisi Nonwoven Products Co., Ltd.) on the cotton cloth, and the spray amount is 1.5g / m 2 ; After the glue spraying is finished, the PE film is laminated with the cotton cloth and subjected to hot pressing treatment with a pressure of 2.0kg / m 2 , The speed is 40m / min.

[0019] Sewing and filling of anti-drilling velvet fabric: iron the coated fabric flat, use a No. 11 sewing needle, the needle density is 8-9 stitches / cm, and sew along the margins of 0.5cm on both sides. 0.5cm to 1cm, and return to the original thread (sewing three and a half sides); then, put the white duck down with 75% down content into the bag, sew the bag mouth a...

Embodiment 2

[0030] A kind of processing method of anti-drill fleece fabric, processing method is the same as embodiment 1:

[0031] The difference from Example 1 is that the textile fabric adopts silk jacquard fabric fabric, and the down bag is processed, and the film covering and filling process are the same as in Example 1.

[0032] Specifications of the silk jacquard fabric used:

[0033] The thickness is 20mm; the warp and weft density is 110*52 / cm

[0034] Finished door width 2.8m

[0035] Yarn count: Warp 2 / 20 / 22; Weft 4 / 20 / 22

[0036] Structure: five pieces of satin

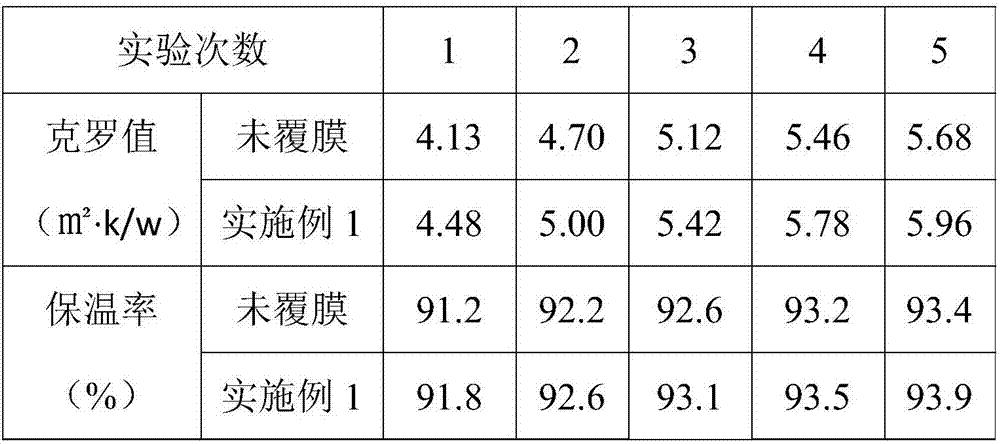

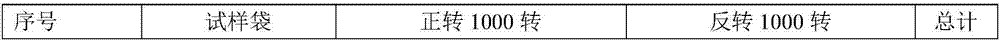

[0037] Utilize the uncoated silk jacquard fabric fabric to prepare down products by the same stitching and down filling method, then test with the down products prepared in Example 2, and test the anti-drilling properties of each sample bag: check whether there are sundries in the box and the remaining down, and then put it into a clean rubber ball and a sample bag to be tested. The number of preset rotations is ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com