Multi-component adhesive mixing device and mixing method thereof

A mixing device and adhesive technology, applied in the field of architectural decoration, can solve the problems of waste of adhesive, influence of bonding performance, uneven proportion, etc., to improve the stirring effect, avoid the problem of inconvenient cleaning and machine damage, and improve the uniformity and work efficiency. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] The present invention will be further described below in conjunction with the accompanying drawings of the description.

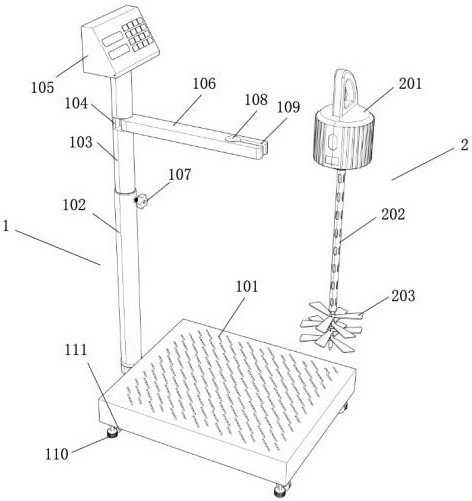

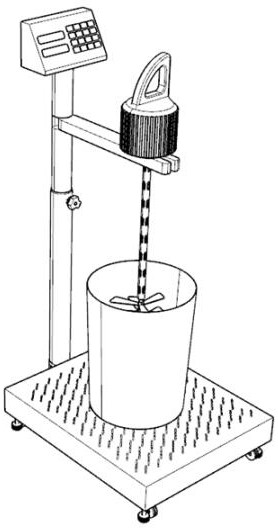

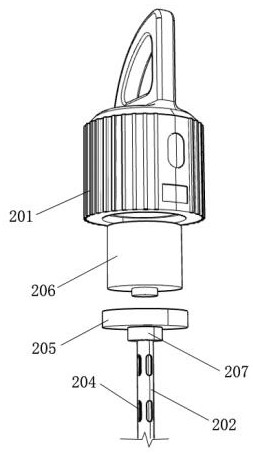

[0031] Such as Figure 1-6 As shown, a multi-component adhesive mixing device includes a weighing device 1, a weighing instrument 101, a sleeve 102, a pull rod 103, a movable connection notch 104, a display 105, a rotating support rod 106, a threaded knob 107, Arc-shaped through groove 108, straight through groove 109, fixed foot 110, folding roller 111, glue mixing device 2, shell 201, stirring rod 202, stirring paddle blade 203, cleaning filter port 204, hollow shaft motor 205, cleaning agent container 206, Coupling 207, cleaning spray port 208, funnel port 209, cleaning agent outlet 210 and rotary valve 211.

[0032] A mixing device for multi-component adhesives. The device part is mainly composed of two parts: a glue mixing device 2 and a weighing device 1. The weighing device 1 includes a weighing instrument 101 and a height adjustment rod fixe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com