Tool manufacturing method special for radiant tube machining

A manufacturing method and technology of radiant tubes, applied to metal processing equipment, metal processing machine parts, positioning devices, etc., can solve the problems of low efficiency and cumbersome processing steps, and achieve the advantages of convenient use, high processing precision, and adaptability to mass production Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

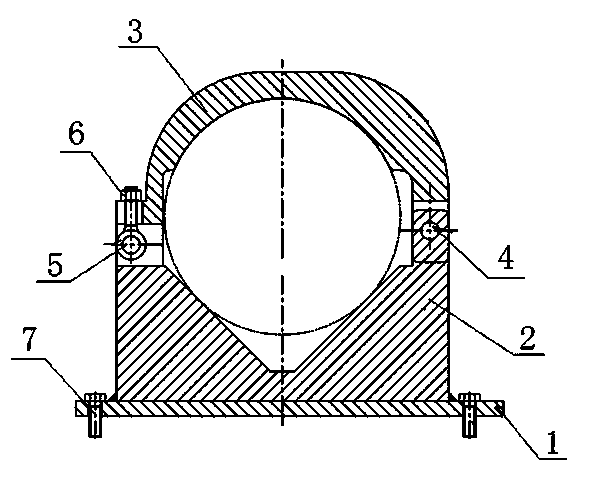

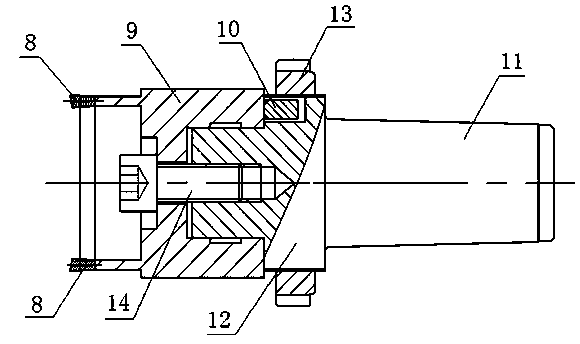

[0021] refer to Figure 1-Figure 2 , the manufacturing method of special tooling for radiant tube processing of the present embodiment, its manufacturing steps are as follows:

[0022] Make the positioning mechanism according to the drawings: fix the V-shaped base 2 on the bottom plate 1; set the rotating pressure plate 3 on the V-shaped base 2 and cooperate with it, and one side of the rotating pressure plate 3 is connected with the V-shaped base 2 through the rotating pin 4, The other side is connected with the V-shaped base 2 through mutually matched bolts 5 and nuts 6 .

[0023] Make cutter mechanism according to drawing: make knife cover 9, the beginning of knife cover 9 is provided with the weld groove that symmetry cooperates with cutter head 8, and cutter cover 9 end both sides are respectively fixed with cutter cover anti-rotation plate 10; Be fixedly arranged on the welding groove of knife cover 9; Make cutter connector, connector one end is cone 11, and the other e...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com