Fixed bed catalyst preparation method and fixed bed catalyst

A technology of catalyst and fixed bed, which is applied in the field of preparation of fixed bed catalyst and fixed bed catalyst, can solve the problems of high impregnation temperature, low production capacity, poor heat dissipation effect, etc., and achieve good impregnation effect, improved quality, and uniform impregnation Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

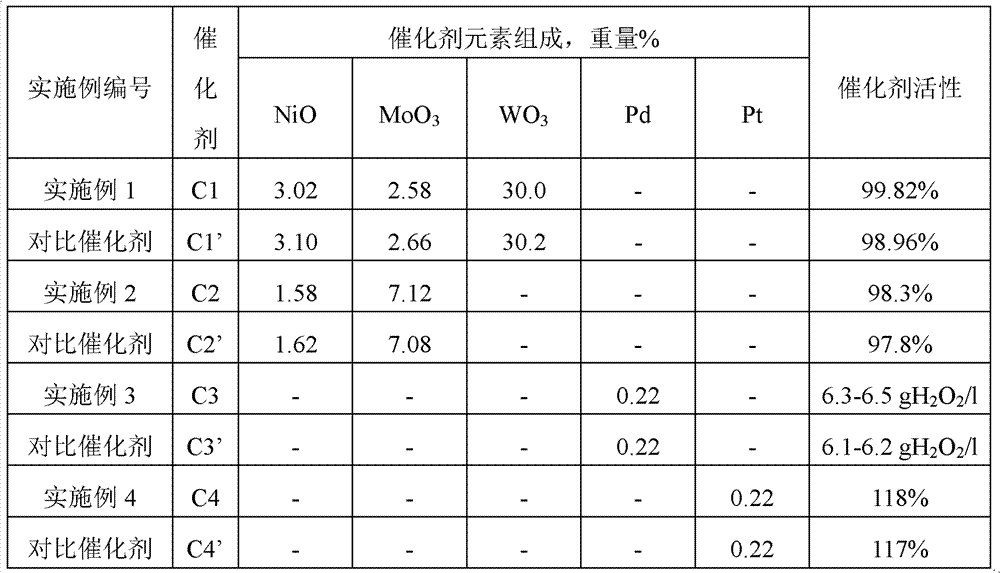

Examples

Embodiment 1

[0069] This example is used to illustrate the preparation of the hydrogenation catalyst provided by the present invention.

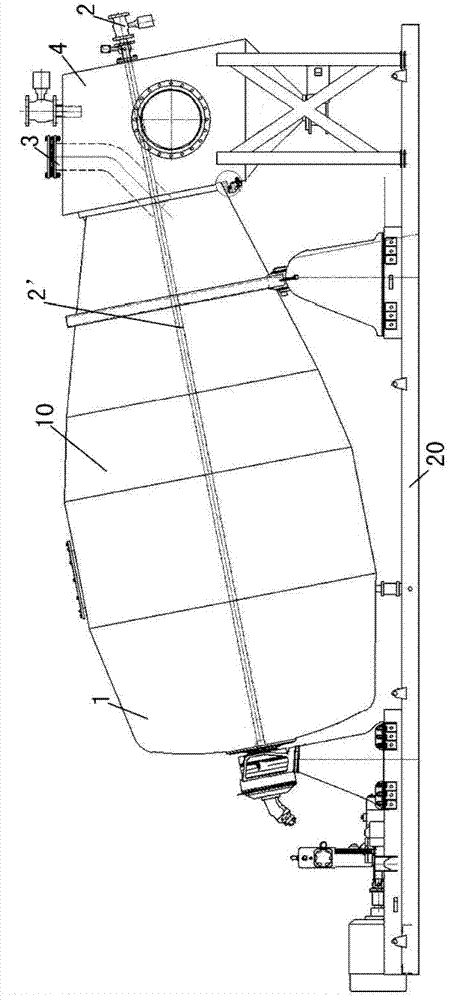

[0070] Prepared as follows figure 1 The macerating machine shown.

[0071] Described macerating machine comprises the cylinder 10 that is inclined to be arranged, driving device (not shown in the figure), feeding device 3, discharge device 4 and base 20, and described cylinder 10 is arranged on the described base 20 obliquely, and the cylinder 10 The tilt angle is 11 degrees. The drum 10 includes a rotatable cylinder body 1, a spraying device 2, and a feed device 3 and a discharge device 4 arranged at one end of the cylinder body 1, and the feed device 3 and the discharge device 4 pass through the cylinder body The mouth of one end of 1 communicates with the inner space of the cylinder 1, and the feed device 3 and the discharge device 4 are respectively sealed and connected with the cylinder 1; the inner diameter of the cylinder 1 is 1.5 meters, and th...

Embodiment 2

[0077] This example is used to illustrate the preparation of the protective layer catalyst provided by the present invention.

[0078] Prepare according to the method of embodiment 1 such as figure 1 The impregnation machine is shown, and its catalyst is prepared, the difference is that the Raschig ring activated alumina carrier S2 (Al 2 o 3The content is 98.5% by weight) (purchased from Yixing Chiba Non-metallic Materials Co., Ltd.) 1000kg is continuously sent into the cylinder 1 through the feed device 3, and vacuumized for 30 minutes, so that the relative pressure (gauge pressure) in the cylinder 1 Be-0.02Mpa, will contain 94 kilograms of ammonium paramolybdate (MoO 3 Content is 81% by weight) and nickel nitrate 72.5 kilograms (NiO content is 25% by weight) aqueous solution 870 liters, under the effect of compressed wind (wind pressure (atomization pressure) is 0.5MPa), at 25 ℃, after spraying The pipe body 2' and the nozzle of the device 2 spray the above-mentioned aque...

Embodiment 3

[0082] This example is used to illustrate the preparation of the anthraquinone hydrogenation catalyst provided by the present invention.

[0083] Prepare according to the method of embodiment 1 such as figure 1 The impregnation machine is shown, and its catalyst is prepared, the difference is that the cylindrical activated alumina carrier S3 (Al 2 o 3 Content is 98.5% by weight) (purchased from Sinopec Catalyst Changling Branch Company) 1000kg is sent into cylinder 1 continuously through feeding device 3, and vacuumized for 30 minutes, so that the relative pressure (gauge pressure) in cylinder 1 is- 0.02Mpa, 800 liters of chloropalladium acid aqueous solution containing 2.2 kilograms of palladium will be passed through the spray device 2 under the effect of compressed air (wind pressure (atomization pressure) is 0.4MPa) by the spray device 2 The pipe body 2' and the nozzle of 2 spray the above-mentioned aqueous solution in an atomized state onto the forming carrier S3 in the...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| angle | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com